Well if I might just defend my self. See posts on 1/1/10 where the issue of stretch against HT or mild was specifically addressed.

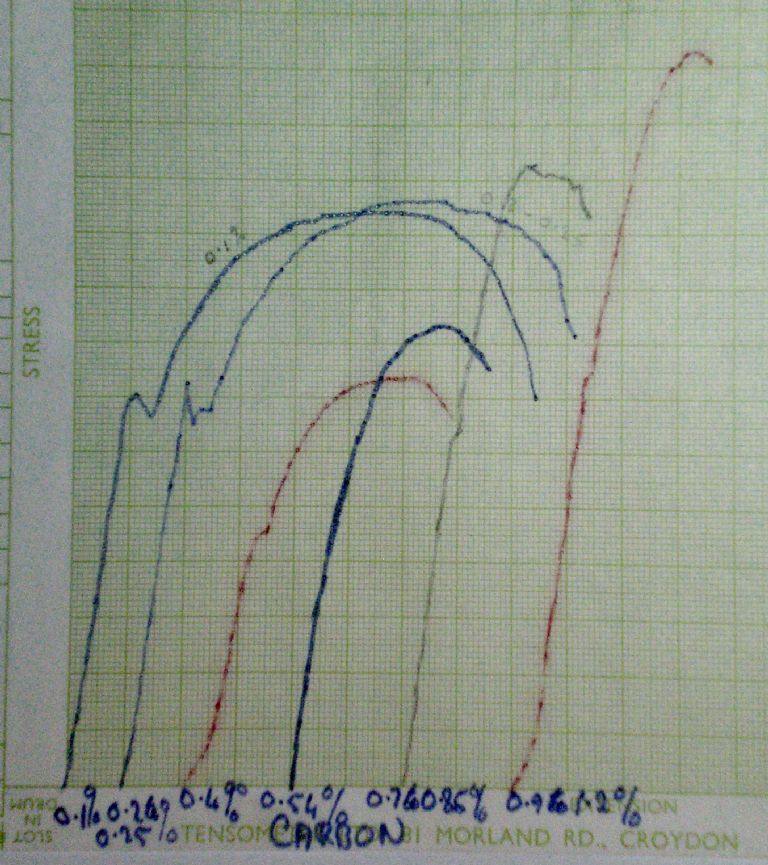

Metallurgical theory – not really. Its actually very basic strengths of materials, which every engineer has to know about. In the same way that women when discussing lingerie ask what colour it is, when it comes to materials, engineers want to know UTS, yield and Youngs modulus of Elasticity or E.

Is it of use to the model engineer, in the conext of this post, and others? Depends on your point of view

If you’l pardon the Freudian slip, with my milling hold down tackle I have deliberately used HT kit more recently, but I have sized my nuts in mild so they will strip before studs, tee nuts and table are damaged.

Just recently I made the point to ChrisH that that some driving crankpins on a model of Metre Maid were safe as houses. An approximation since I ignored any bending moment, but good enough. Then I did the caclulation for the mild conrod and coupling rod bolts specified in the drawings. You get about 7ton tensile in that, for a yield of about 12 tons. safe – well yes, until you add in in the preload geneated by the nut. and of course its a cycling or reversing load. So those are a scrapbin job – just for insurance.

Or on my traction engine. Ordering springs for the safety valves. If you can do the maths without taking shoes and socks off , its pretty easy to end up with the right length of spring, at the right rate, so it fits the turret and works first time. (I had other problems, but spring rates which is the common issue, were not amongst them)

Or the great front and rear toolpost parting off argument, when its very obvious why parting tools jam, and the cure very simple. (Though I have carbide tipped parting blades, I use Eclipse left and right hand ground blades much more often and since Chris Stevens got me to took at the problem properly, It has simply been solved))

So yes, strengths of materials and the associated mechanics or resolution of forces and vectors, affects us as engineers every day of our lives, consciously or otherwise, and sometimes by omission, when something breaks which could easily have been avoided.

At the end of the day, materials and mechanics are what engineering is about -, don’t knock it till you have tried it, because a calculator saves a hell of a lot of grief.

Edited By mgj on 04/02/2011 01:55:11

Ian S C.

.

.