I don't know the material of the slideway itself, but isn't the 'Peatol' lathe bed a hollow aluminium alloy extrusion filled with a special form of concrete?

This is not really any different from the system I have read a major German manufacturer using for building massive machining-centres, though their casings are welded steel fabrication.

I worked for several years for a leading maker of very high-precision screen-printing machines used in electronics-component manufacturing. These machines had, and their successor designs still have, fabricated steel frames bearing large aluminium-alloy plates machined to complicated shapes as the bases for the moving parts.

My role was materials store-keeper, when the company made a lot of the machine parts itself. Among the stock materials I had to order, read off the drawings, was a lot of aluminium "tool-plate". I am not sure of the alloy grade but it was simply wrought plate machined or ground to precise thicknesses and flatness.

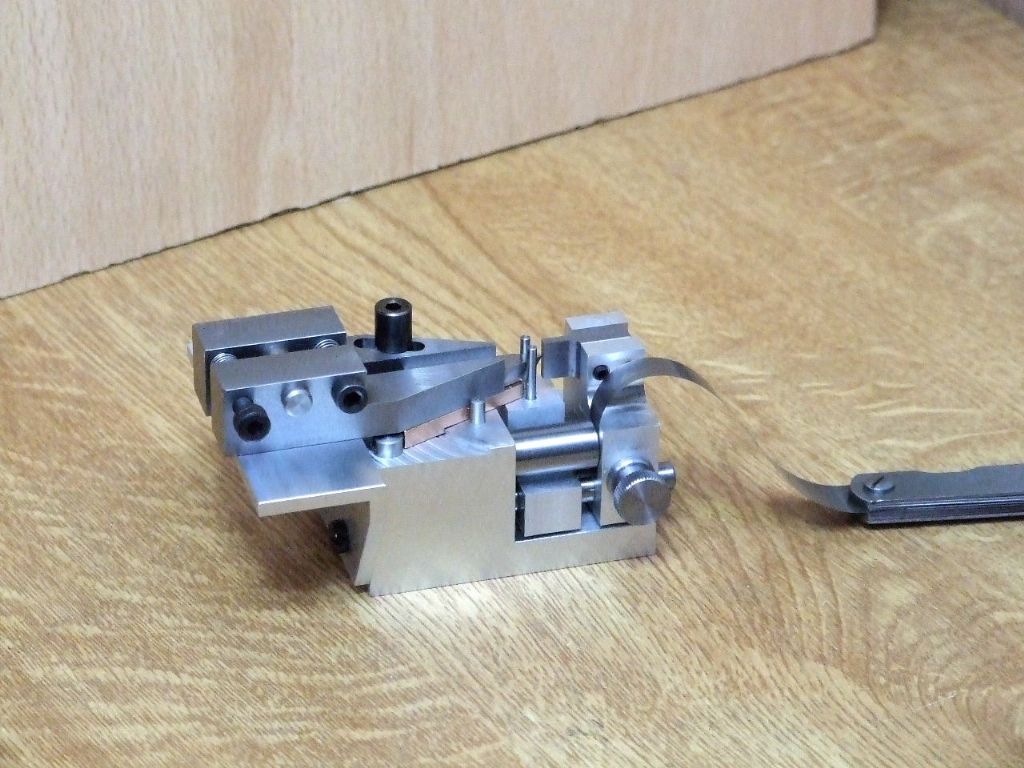

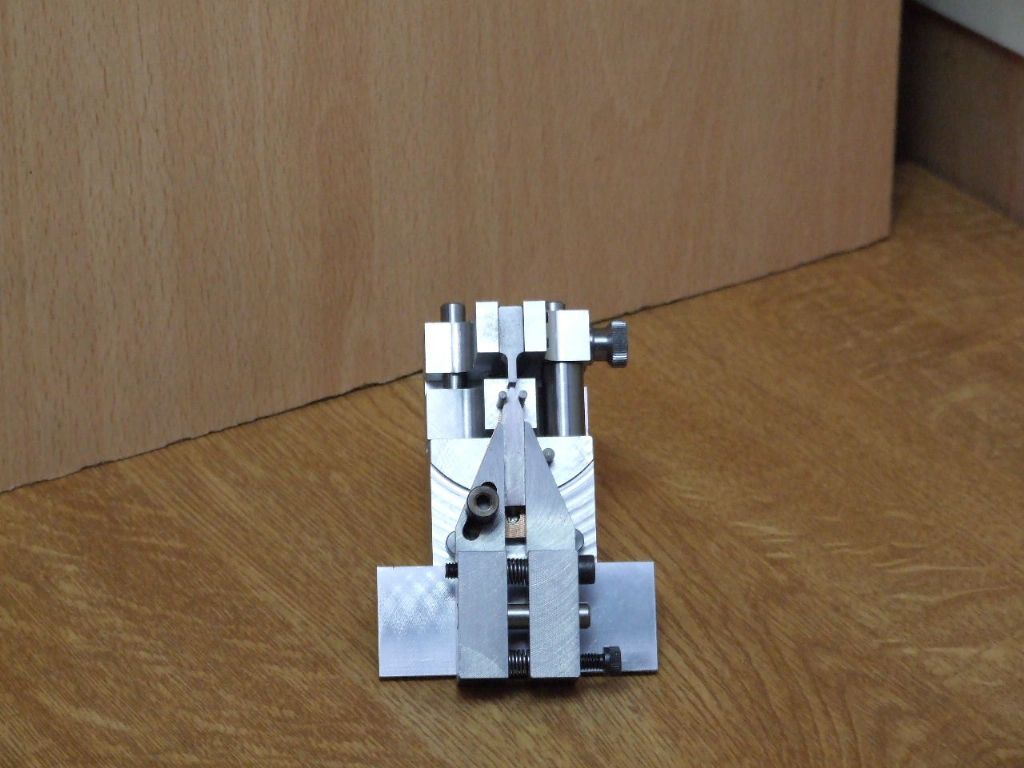

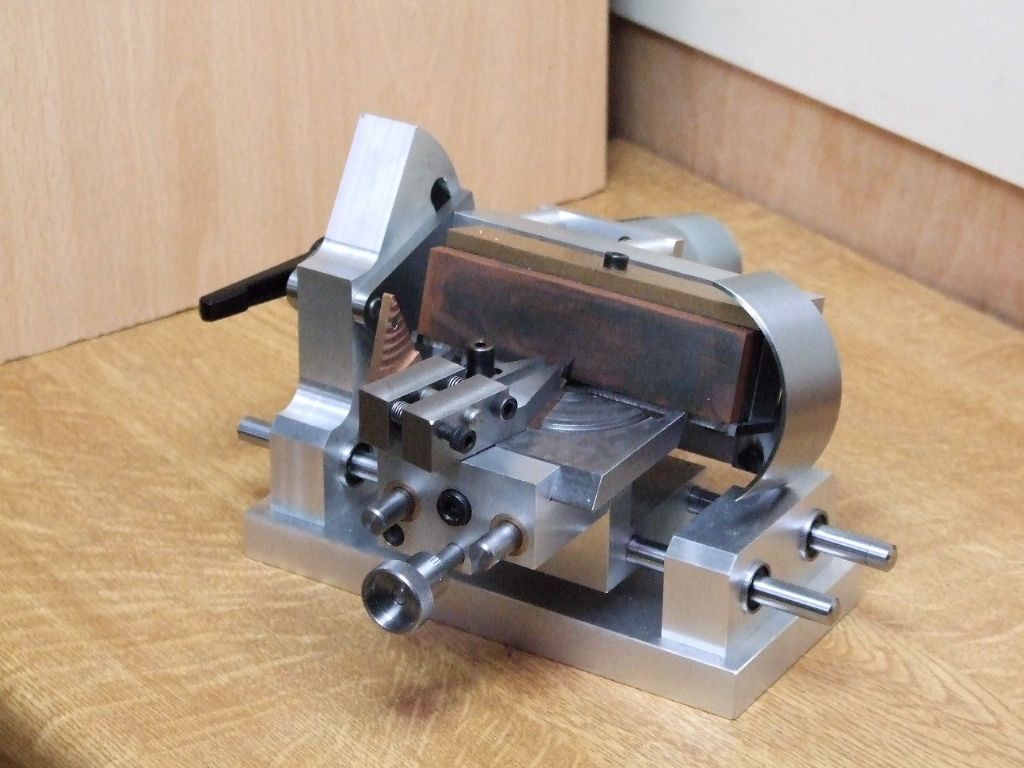

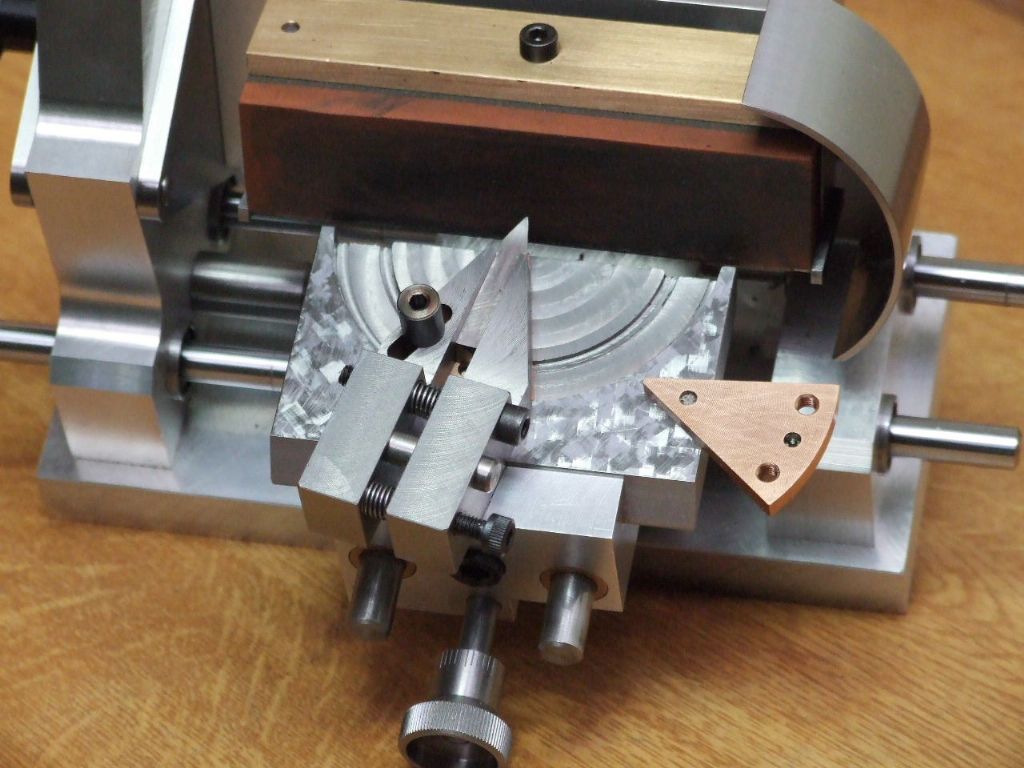

No – there is no logical reason why this tool-grinder could not be made from aluminium alloy.

Same with the commutator lathe cited by Neil Wyatt. I would envisage such a lathe, designed for a special, light task, as having its aluminium-alloy saddle fitted with linear bearings running on parallel round bars rather than dovetailed bed; extending through the end-plates of a box-pattern headstock.

As for purists, I recall at one major exhibition, overhearing one say agree with his pal that some minor detail was "wrong", on the machine I was admiring. It was a traction-engine to 3 or 4-inch scale, clearly well-built but not newly, carrying the honourable patina of a well-loved engine that had seen a rally-field or two, as intended. I wondered which were the critics' exhibits…

Neil A.