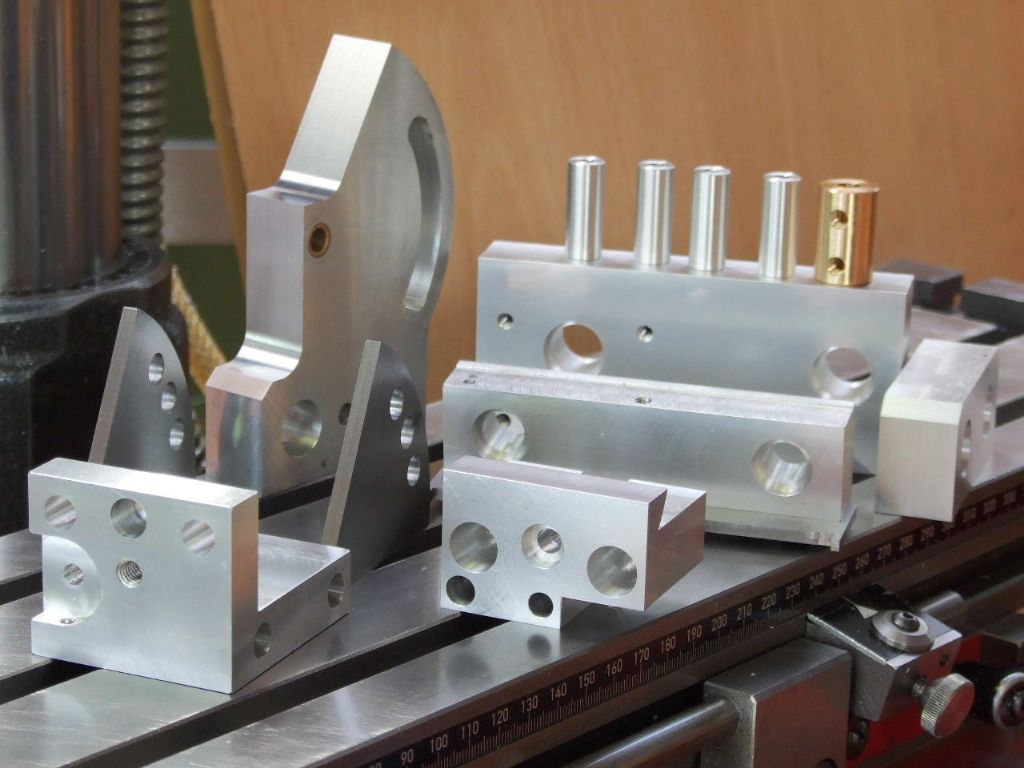

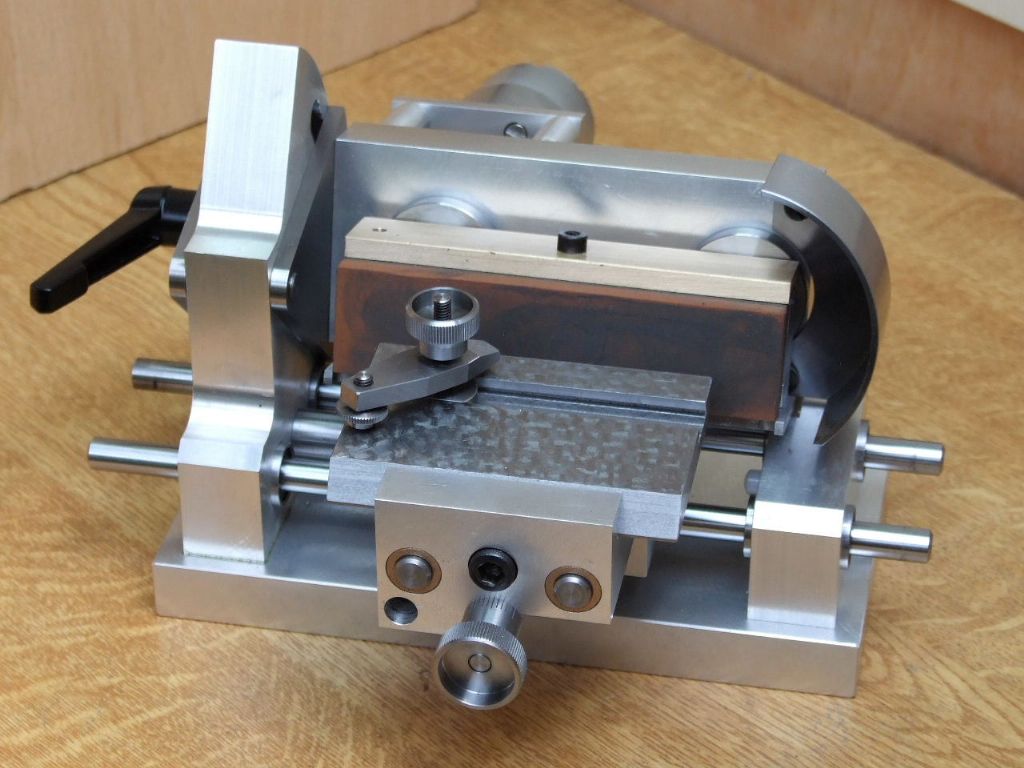

As promised a few days back here are some more shots of the Lathe Tool Honing Machine,

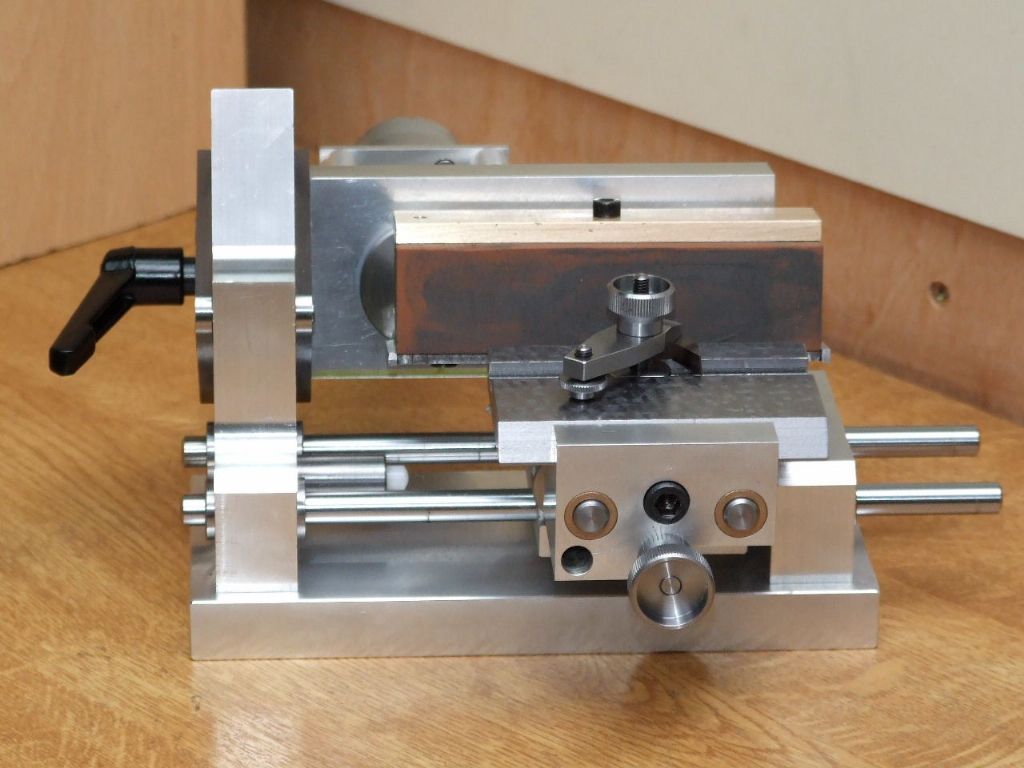

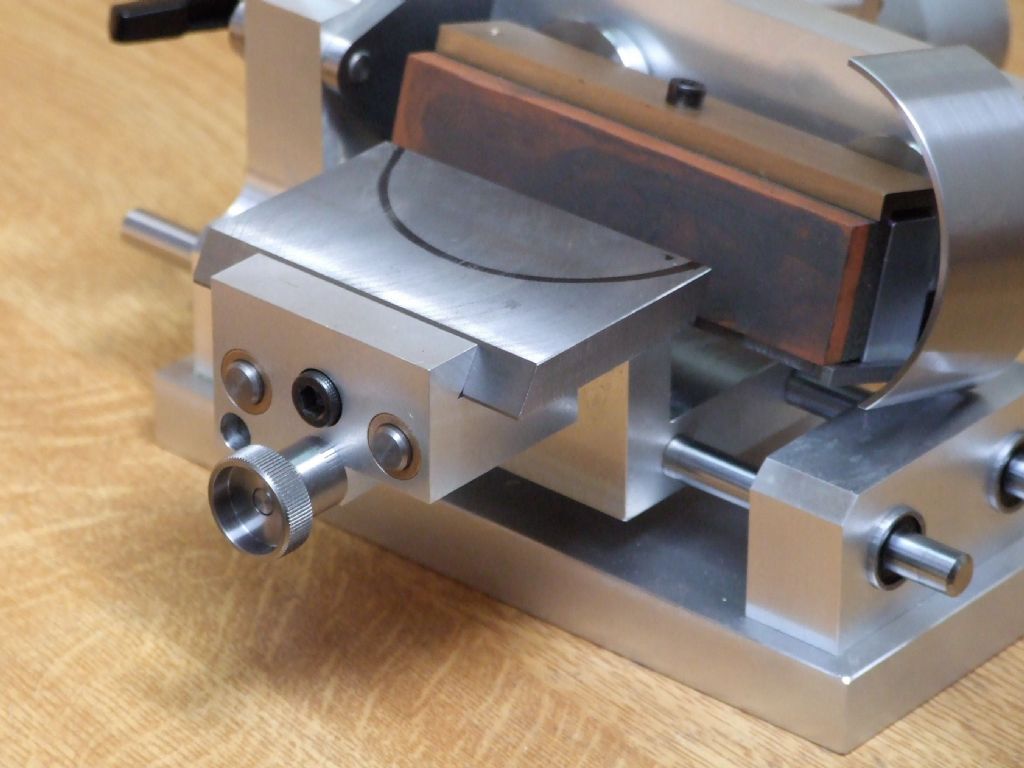

This view differs from the previous one in that a Guard has been added to the Rt hand side. With the stone rotating clockwise there was a distinct pinch hazard.

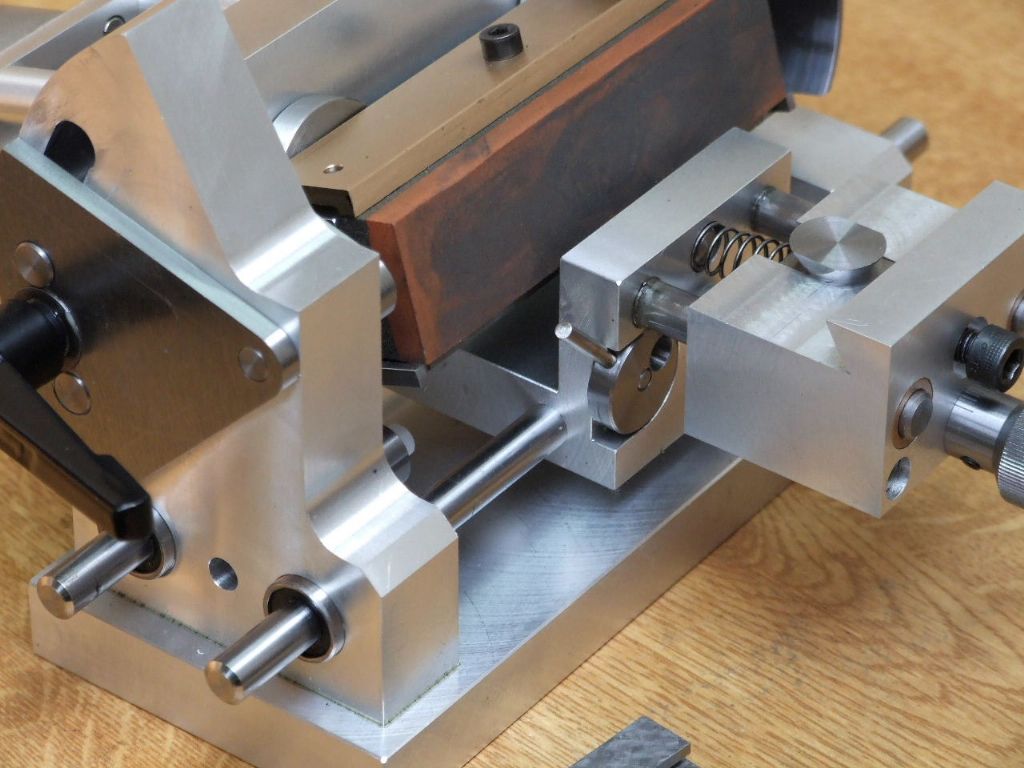

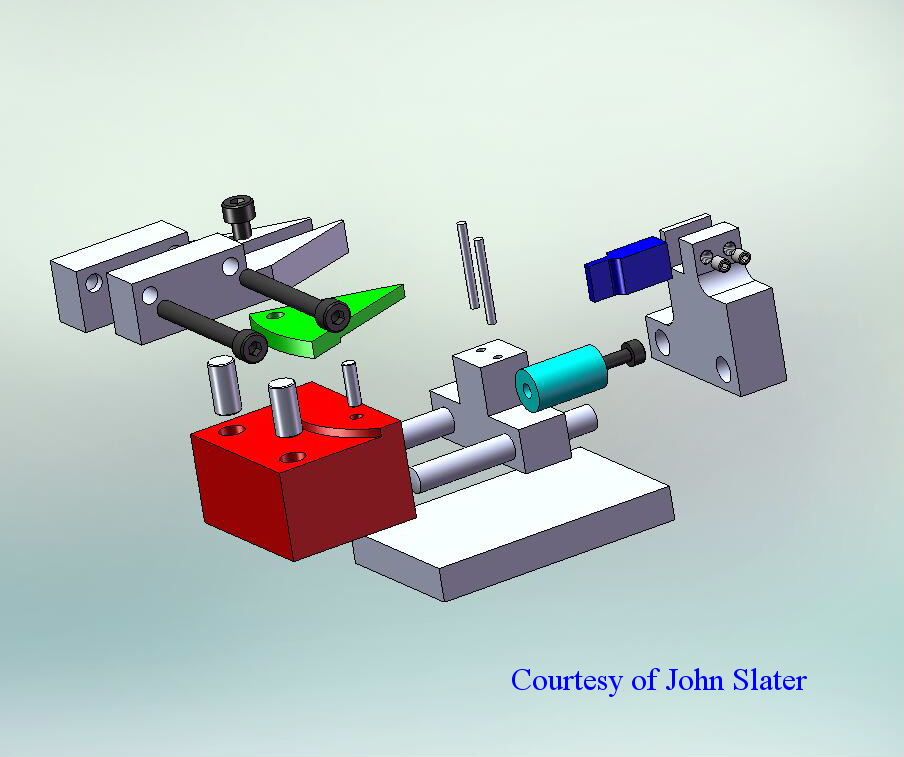

This second view shows several things,

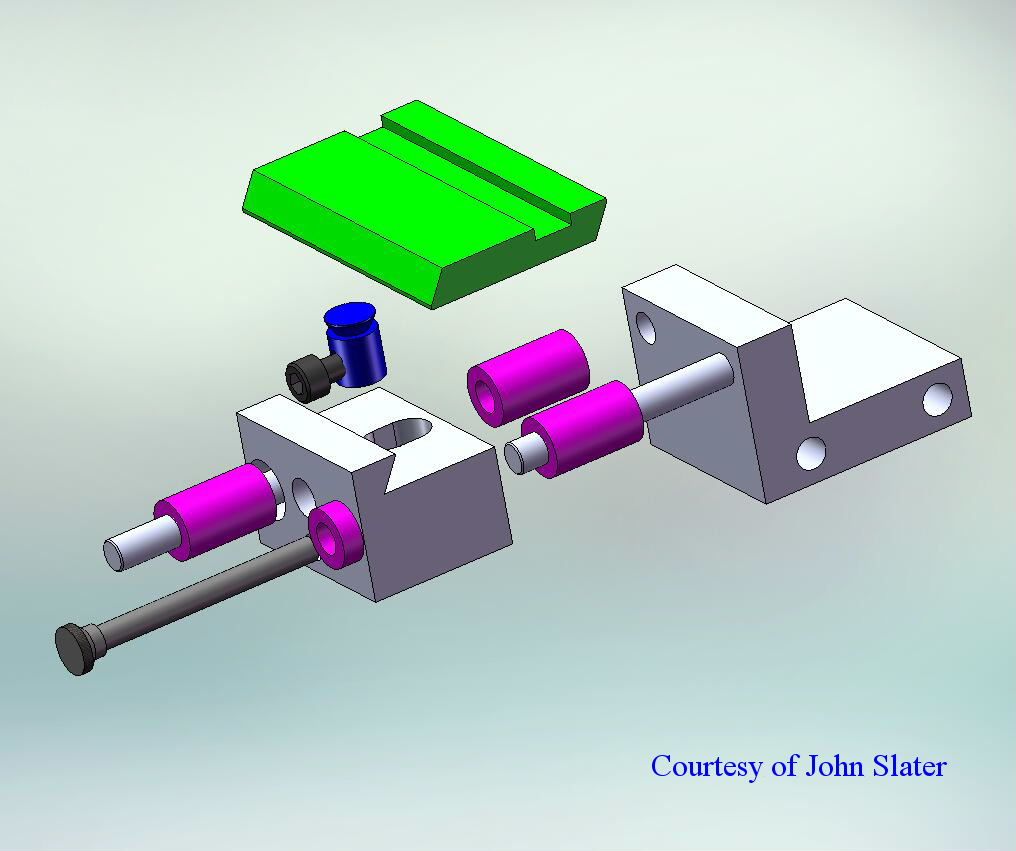

First is the Spring loading that automatically retracts the table and also automatically locates the interchangeable tables in position for locking. The nature of the clamping mechanism means the complete table with the tool still set up can be removed for closer inspection with no loss of positional settings.

Secondly is the two position Deadstop. The primary use of the deadstop is when doing radii with the additional table, (more on that later). It also stops any collision between the edge of the table and the Slip stone.

This view shows the Deadstop in position 2, the hole in the stop allows the table to be advanced by a measured amount past the datum position by using the adjustable stop. The graduations on the collar of the adjustable stop can be seen in the first photograph. This collar is only graduated with 10 of the full compliment of 40 divisions as each division is 0.025 mm or 0.001". I could not foresee a need for removing 1 mm with a hone.

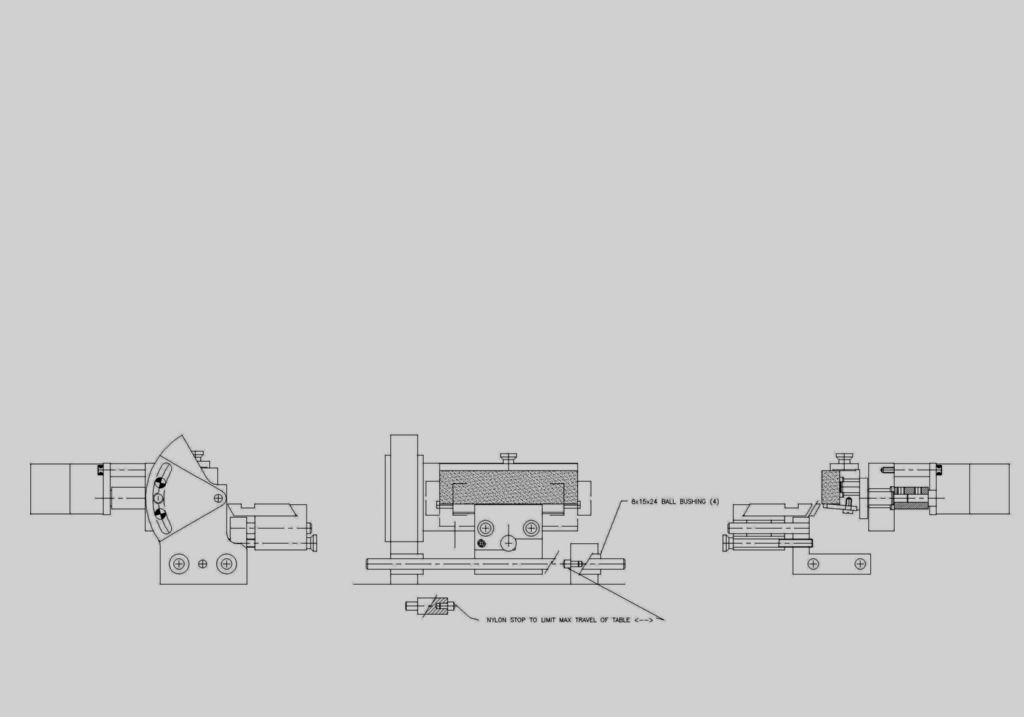

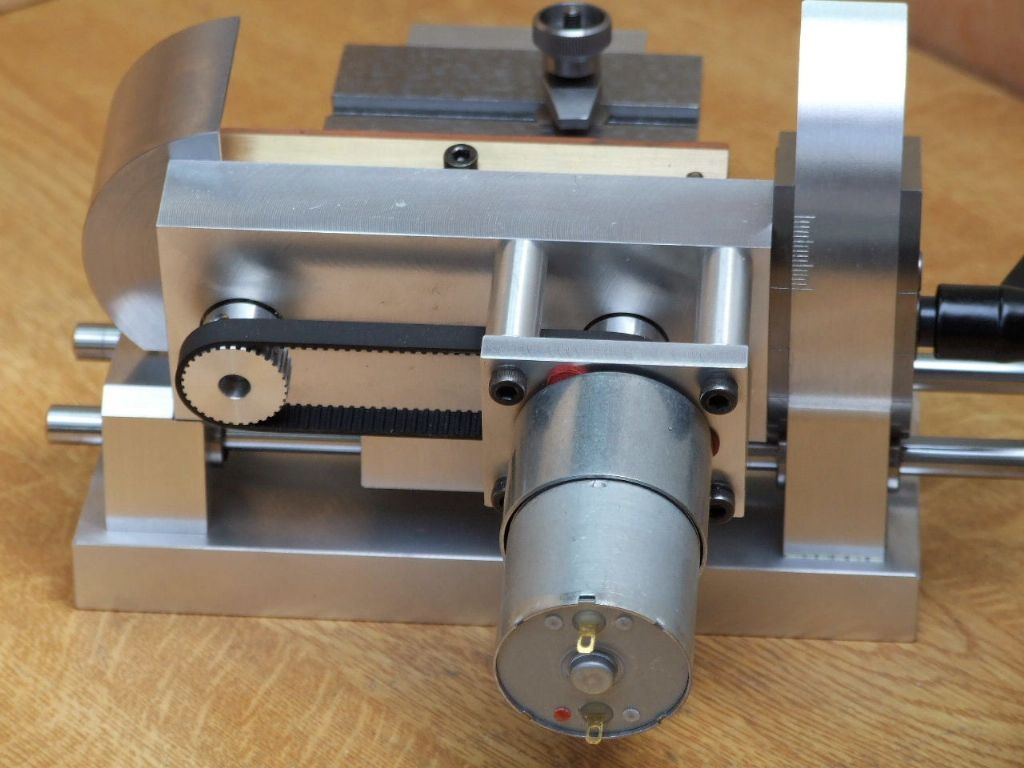

A Rear view of the machine showing the drive to the two cranks. The belt is kept in check by a cutout in one of the Motor support pillars so no washers are needed on the pulleys. The graduations on the degree scale can be seen in this view.

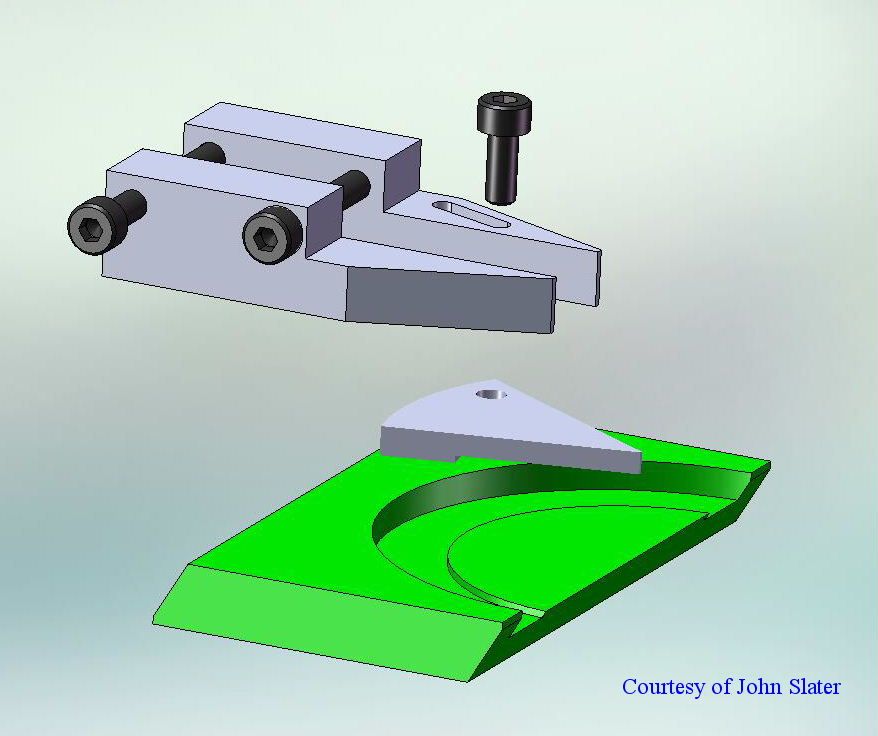

This view shows the second table in position for doing the radii, but as yet not fully machined. The felt tip marker traces out a semicircular cut-out to take the tool bit holder. The details of which will be posted soon.

Regards

Gray,

Edited By Graham Meek on 15/09/2020 14:57:15

Neil A.