The DRO works. Bargain.

X is neat:

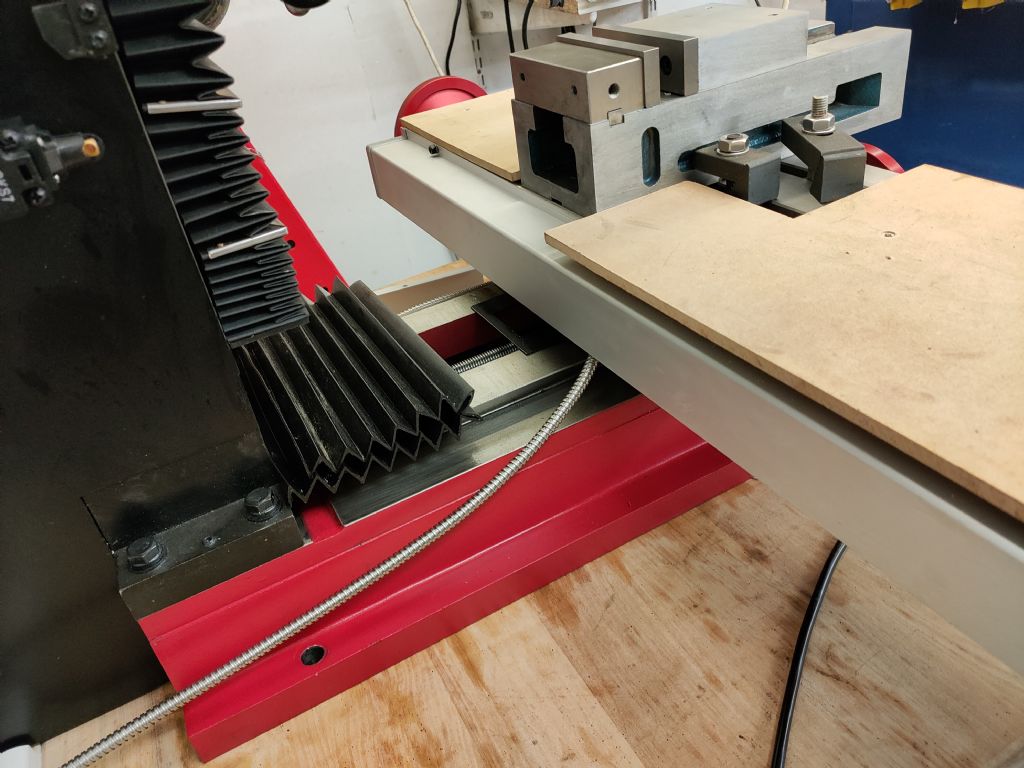

I'm a bit worried about Y – I should really turn the scale up the other way to minimise dirt getting in (for now I leave a bit of extrusion resting on top).

Does anyone want to encourage me to turn it upside down, or do some people live with a scale this way up?

Tips for installation:

I started trying to complete the install without any dismantling of the mill but it is so much easier once you do! And tapered gib strips make is simples.

Again I am glad I got this size of machine and not any bigger – the cross slide is about as heavy as I would like to handle on my own without any assistance.

Thoughts on the SX3.5

The flaking paint issue is extensive on my mill. I was forewarned so I'm managing not to let it bother me. Be careful to check if paint is going to bother you!

The X power feed installation feels like it lets the side down. The electronics and motor are fine, but the hosing is thin plastic and will not last much longer. I have had to take the cover off a few times and if you put the wrong screw in, or over tighten, then the plastic cracks and that screw hole is then no good. I got 2 screws left holding the panel on… and they come undone because I don't want to over tighten like I did the others. I thin I will be 3Dprinting a new box within 12 months. The wire to the limit switch dangles around … not sure what the soln would be though. The power is via a separate brick about the size of an old laptop power supply, and the power input socket has its threads stripped so dangles out the box. Note that there are extensive power supply options hidden in an enclosure behind to column so a nice soltion would to have been to provide the power from there.

The column is no where near as massive as it seems in the sales pictures – most of that is a steel sheet covering to enclose the power and electronics.

The Z power lift however is a nice install. Enclosed power supply, hidden wiring etc.

The quality of finish, including surface finish, tends to be good enough and no more. An example is the gib strip. Where you might expect a scraped surface, you have the same effect but achieved with a hand held grinder. The actual points of contact are probably less than 10 across the whole gib – but these are at the extremes so it does its job. I don't know what impact this might have on wear.

The rest of the wiring and circuit boards are all neat.

As far as being a good or bad mill… I have no idea as I have nothing to compare to. But if you are buying, then be prepared for the above and you will be much more likely to avoid dissapointment.

David George 1.

David George 1.