I am not sure I agree with all the deriding statements re a round column mill. It IS less rigid than a decent dovetail column, but the limitations are very easily endured IF the mechanical setup is properly adjusted, as for ANY dovetail arrangement. Any loose adjustment anywhere critical will show up on any type of mechanical arrangement. I have 3 Emco mills now for over 25 years and if you might care to take a look at my albums you may see a large variety of work having been successfully executed on them. One of the three has been converted to full CNC with ball screws, and has milled full 3D work, with CNC motion in Z, of course requiring that the head can move up and down freely, aligned only by the properly adjusted slide screws and the gib. Granted, I do not do the type of Heavy Steam Generation work such as Jason does, but milling 25mm deep dovetails on phosphor bronze, with a 75mm diameter dovetail cutter is a doddle.

So, Adrian, do not let the naysayers put you off! Unless there is fundamental poor mechanical workmanship in the fit of your mill's parts, correct setup will give you a machine that is a pleasure to use, within its size limitation.

Regarding the 8mm slot drill – repeat the test before doing ANY adjustments and when the head 'vibrates', try to see where the motion takes place, ie, is it the column itself rotating in the base, or the sliding head on the column.

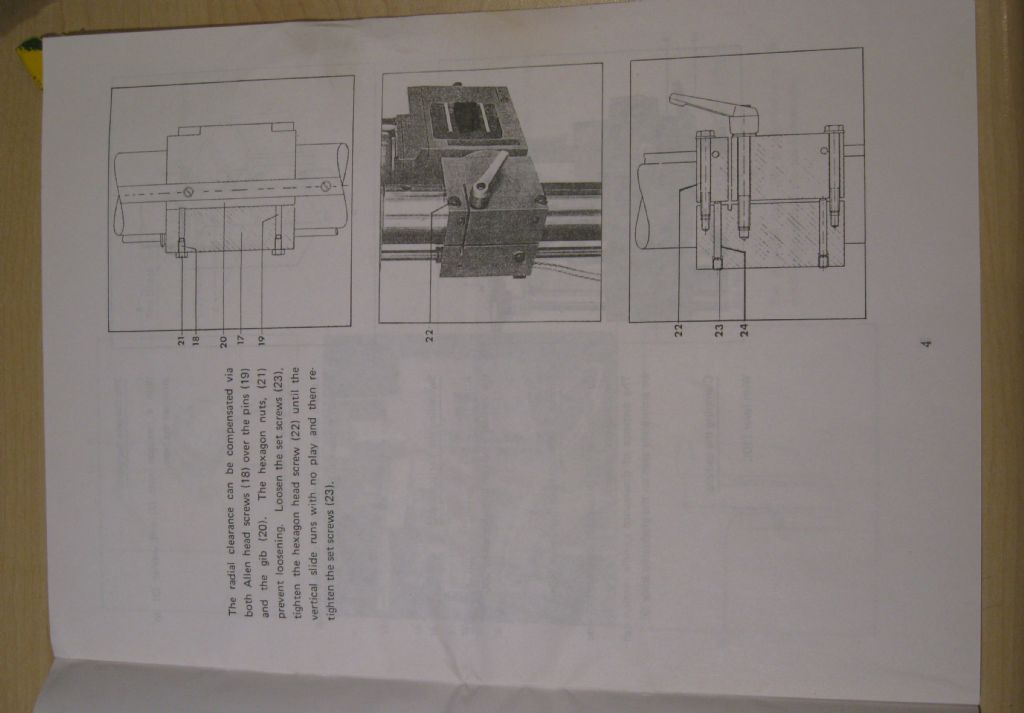

If the base/column junction, snug up those two hex bolts in the side of the base and try again. If not the column, then fasten up the vertical slide clamp, maybe slightly over tight, and try again. It the problem is mostly gone, then you need to do those adjustments as in page 1 of the pics.

Note also that rigidity on these machine does get worse the higher the head is raised..

Joe

ega.

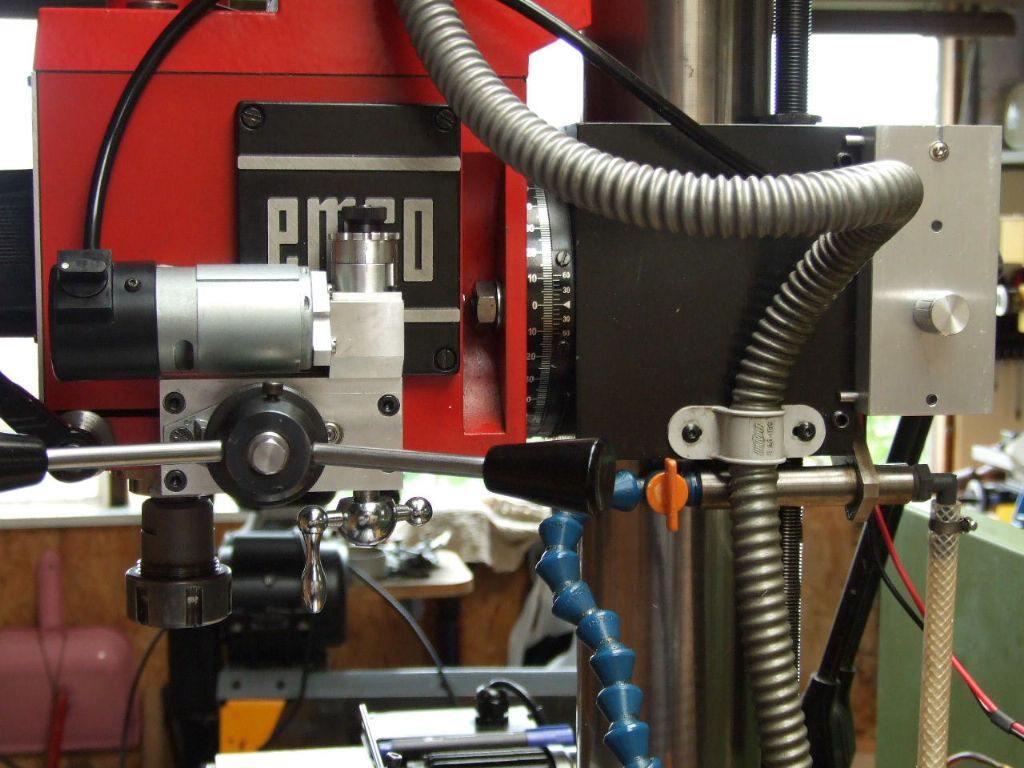

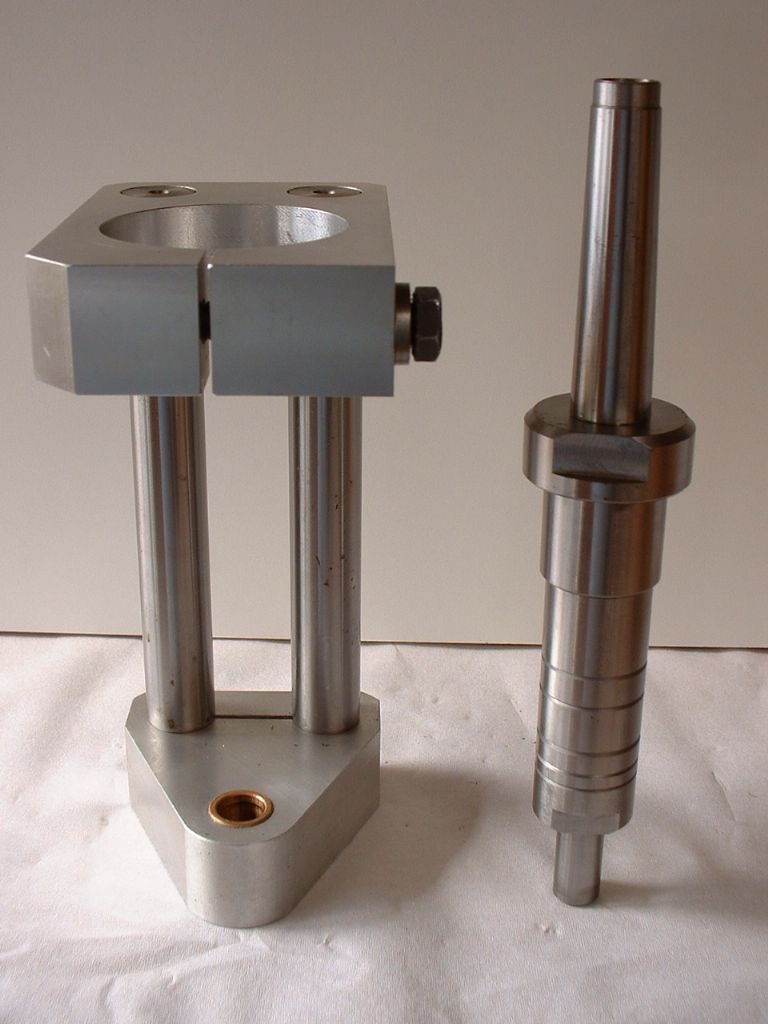

![img_20190701_125903[1].jpg img_20190701_125903[1].jpg](/wp-content/uploads/sites/4/images/member_albums/74097/834050.jpg)

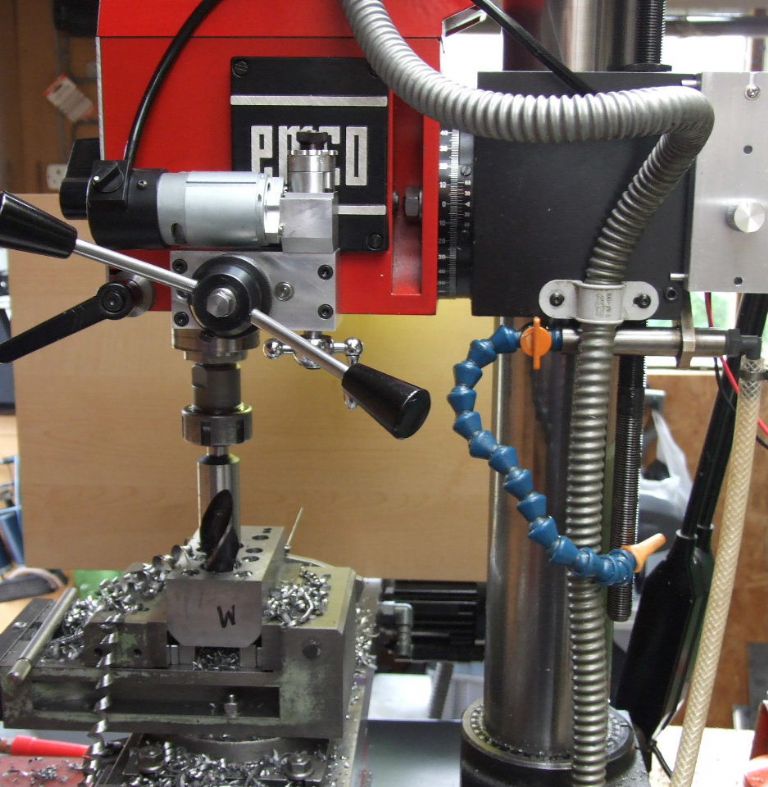

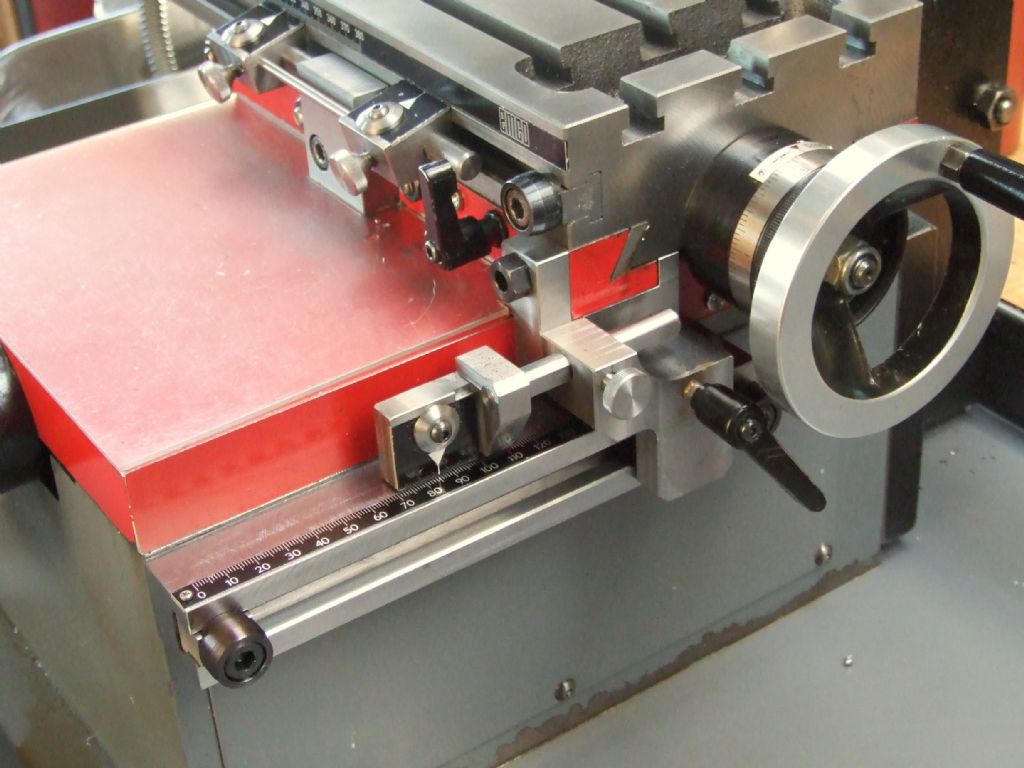

![img_20190701_125929[1].jpg img_20190701_125929[1].jpg](/wp-content/uploads/sites/4/images/member_albums/74097/834051.jpg)