A simple way to draw an ellipse without doing complex sums (etc) is this:

Draw out a circle on graph paper using a pair of compasses, with the centre on one of the major crossing points on the paper, and the radius to the size of the longer diameter required – or some handy multiple of it. Your circle will be divided into strips by the lines on the paper, and we need to look only at the more heavily printed ones, and only those which run up and down the page. Take each such heavy line in turn, and measure the length between the ends where the circle cuts it. This can be done without a ruler or calliper by counting the squares on the paper (but not quite so exactly). Divide this distance by 4. Yes, that is a sum, I know, and a calculator makes this bit quicker. Measure this 1/4 distance up from the equator of your circle, and make a dot, and then do the same down from the equator. Do this for each of the heavy vertical lines, and you will produce an oval ring of dots. Join them up and there is your ellipse.

It doesn't matter whether the diameter of your circle fits exactly with the squares on the paper, or even whether the starting centre is exactly lined up with a heavy line – the method I set out above does not need these details, but it does make the job quicker as the four quarters of the ellipse can then rely on the same measurements each side – you can even fold the first quarter over and mark through, if you are a precise folder. And if you have no graph paper, use lined writing paper with the lines going up and down, and a ruler for measuring.

The result is an ellipse with the vertical diameter just half the horizontal. If you need a different proportion, don't use half the vertical distances, but some other fraction or decimal to do the calculation. If your fraction is larger than 1/2, the ellipse will be more nearly round, and if your chosen fraction is smaller the ellipse will be more pointy-ended.

Useful, sometimes, if for example you need to make a tidy looking car Nationality Plate for a trip abroad (as I did, you might guess).

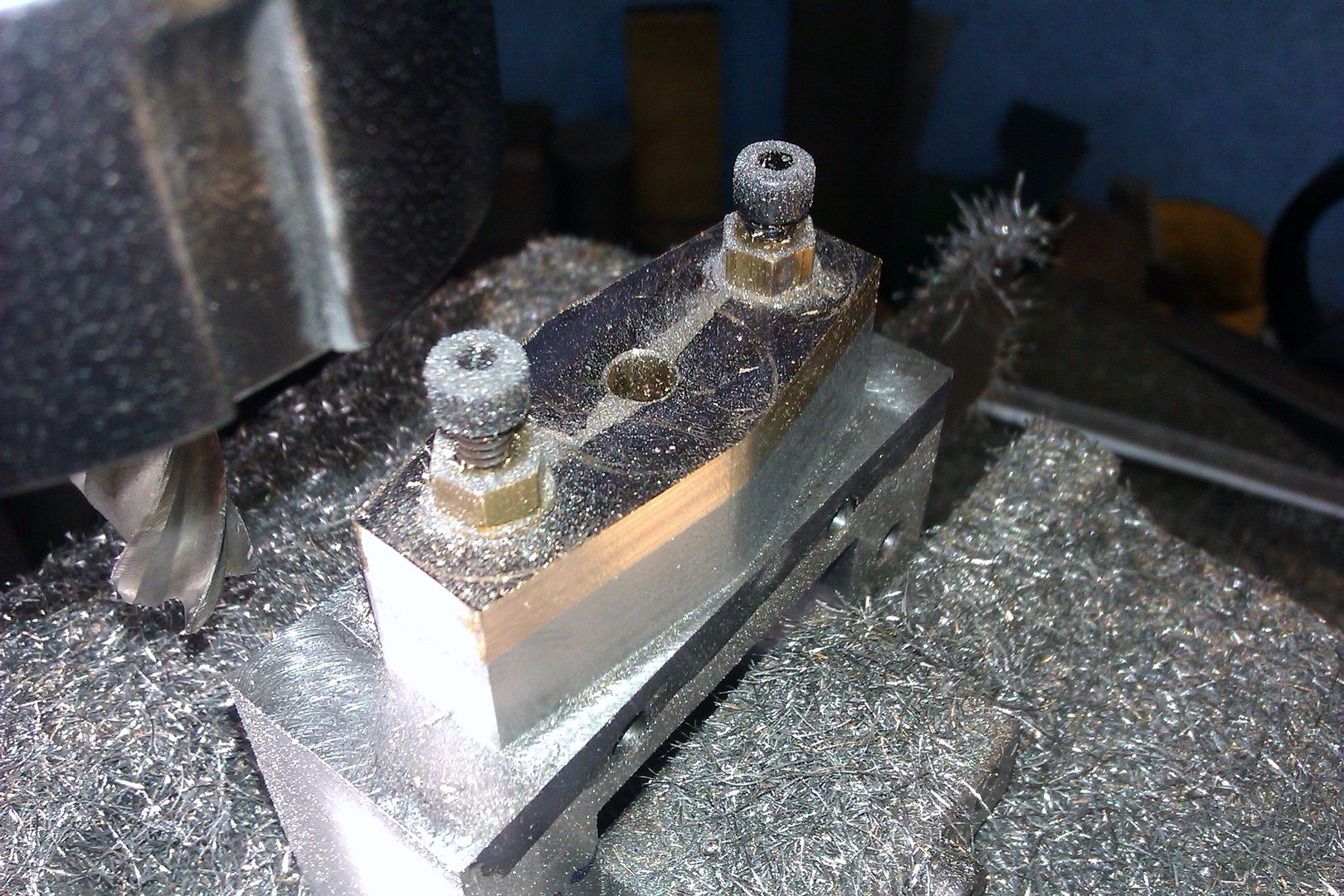

And while I am writing, you can generate a true ellipse using a 'trammel' comprising a pair of followers (like T-nuts) running in two right-angle slots in a cross-shaped construction (one in each slot). Join the two followers with a bar (which can stick out each end if you like) and any point on the bar will move in an ellipse as you slide the two followers along. Winding the handles of your manual mill to trace the correct outline keeping the followers in the slots would make an interesting exercise – rather more difficult than scratching your head and patting your belly, I reckon. Hours of untrammelled joy …

Regards, Tim

Edited By Tim Stevens on 17/07/2018 16:26:21

JasonB.

JasonB.