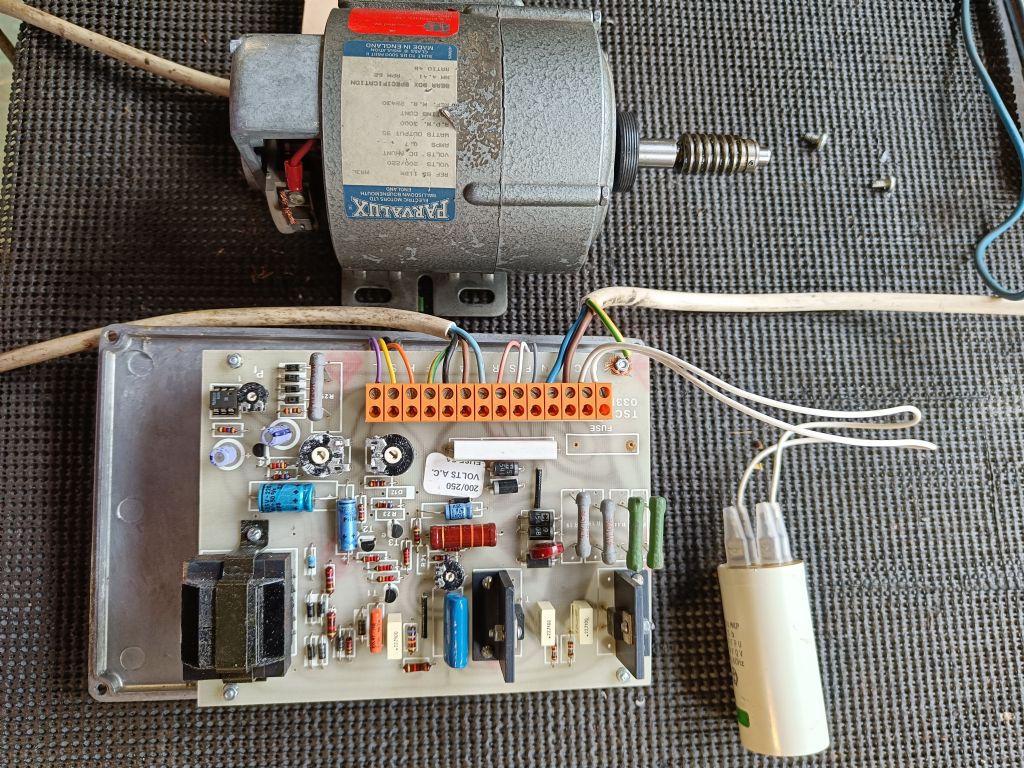

I thought I'd resurrect this thread! I have a similar setup to the examples above, but after less than 10 minutes my Parvalux motor slows down and then stops (in the space of about 30 seconds).

I thought I'd resurrect this thread! I have a similar setup to the examples above, but after less than 10 minutes my Parvalux motor slows down and then stops (in the space of about 30 seconds).

I sent the motor to a re-winding company who checked it and said it was fine, so I'm investigating the controller. Electrics aren't my primary field of excellence (!) and I haven't done the lightbulb test as described above. I figured that I could connect one of the wires for the bulb holder to the wire that should go to the field windings, but where should the other wire from the bulb holder connect? Earth? This is why I haven't done this yet!

My motor will only run with the switch in the "Reverse" position- it won't run at all in the "Forwards". I can get around this mechanically so I'm not too fussed about this. When the motor is running, the speed can be varied quite happily.

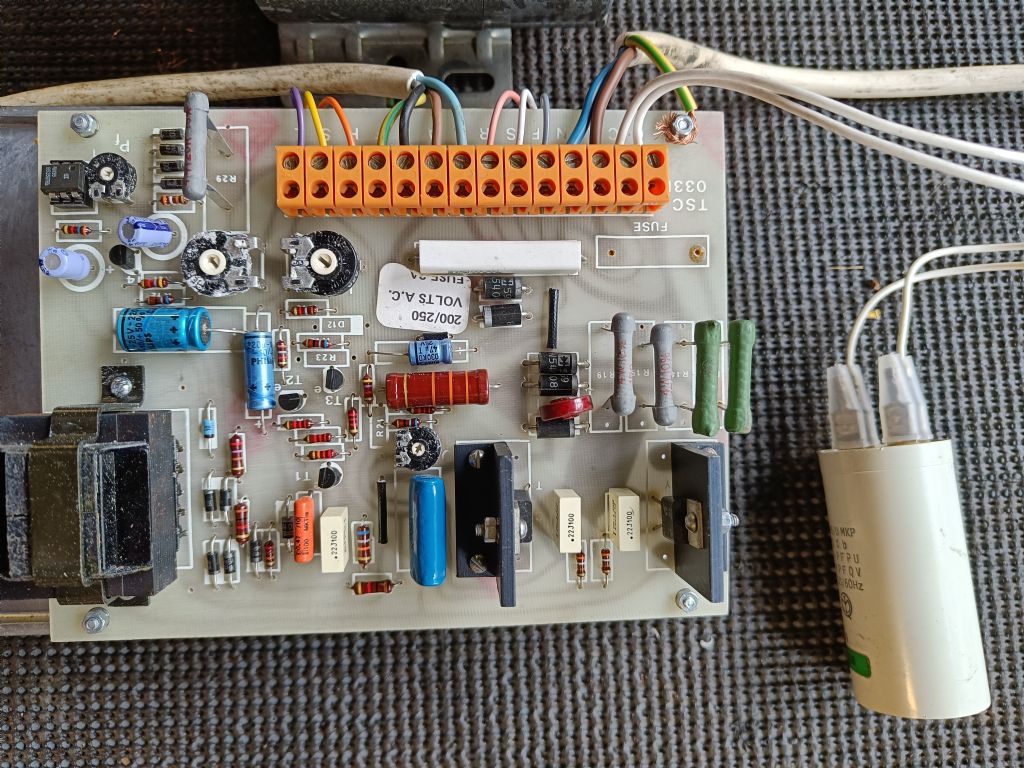

I disconnected one cable to the large white cylinder and the motor wouldn't run, so I guess this is the start capacitor?

Are the two blue cylinders the run capacitors?

I'm also curious as to what the black discs with white plastic circles in the centre are. They have a bit of white oxide-y type powder on them so could be the problem?

It would be really great to get this working as I made all of the mechanical fixtures to drive a positioner and only when I tried to use it properly did it become apparent that it won't run for very long.

Edited By SillyOldDuffer on 03/09/2022 09:13:30

SillyOldDuffer.