X caps are fitted across L-N or sometimes after the bridge rectifier. It's unlikely they would trip the RCD if they went leaky. On the other hand, Y caps are fitted from L and N to ground and could cause tripping. Generally when X caps fail, they will make a lot of noise and a filthy rank smell, blow their sides off and most likely blow the fuse. Evox RIFA (now part of Kemet) probably made the majority of RFI caps out there. Probably a bit of a generalisation to say they are crap, as they have made billions of them and I've not heard of any quality concerns. However, most electronic components have lifetimes and wearout mechanisms, so if it's getting on a bit you might have to forgive the odd failure.

As suggested, you could snip them out and the drive should still work fine but I doubt that's the issue here.

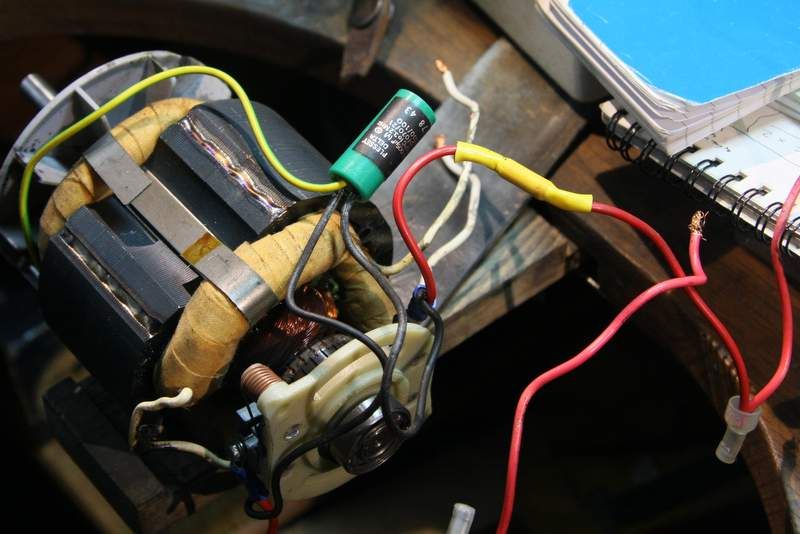

These drives generate a DC current in the field and a variable DC current in the armature (I think that's the right way round). It's possible the motor insulation is breaking down after all these years. If it hasn't seen much use, you might find that leaving it to dry out in a hot place (on a radiator, on a hot water cylinder, inside an old boiler) will help. If you have access to a Megger insulation tester, you could test the insulation between the windings and the frame.

SillyOldDuffer.