Firstly, it's probably easier to search for videos than web articles on how to use your height gauge.

If I'm reading your requirement correctly;

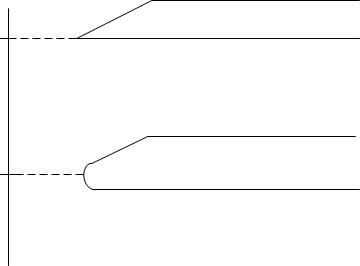

How about the following; bear in mind that lever indicators give the best readings when the lever is parallel to the surface being measured.

I'm assuming you have one of the more conventional DTIs, where there is a lever to change the direction of measurement, rather than a central "both way" indicator needle position.

To maintain any consistency, you need to use the clock in the same direction each time.

You seem to have a metric height gauge, so find or make something, which is an exact sensible measurement, say 1 or 2 cm; lets call it 2cm

Ensure that your workpiece is vertical on your surface plate/flat surface

Set your height gauge to the thickness/height of your test block i.e. 2cm

Add the DTI and zero it on your test block height, without adjusting the height gauge.

Move the workpiece to the height gauge/DTI assembly and adjust the height gauge only for a zero reading for the DTI on the bottom of the hole; you're obviously looking for the lowest point.

Read and record the height gauge reading; add 2cm and that's the distance to the bottom of the hole from the lower edge of the plate.

Find a length of round ground bar which fits in the hole, and clamp/wedge it in place at the very top of the hole.

Now use height gauge/DTI again to measure to the top of the ground bar, this time, you're looking for a maximum reading; read and record the height add 2cm and you have the distance from the top of the hole to the surface plate.

Subtract the two readings and you have the hole diameter, and can easily calculate its centre.

It would help to know what other measuring kit you have, e.g. internal micrometers, slip gauges etc. as well as the accuracy you're trying to achieve; also what size roughly is the workpiece.

Ideally now check your calculations using a different method.

This is quite a good video on why DTI's are often best used as indicators, rather than for direct measurements (unlike plunger clocks), and why I've described taking all actual measurements off the height gauge.

Several good points also made in this one, particularly if your surface plate isn't perfect.

Bill

Edited By peak4 on 08/05/2023 16:33:21

Howard Lewis.