Cheers guys. The finger on mine doesn't go down to the base. I'm presuming at some point it had the old cranked finger replaced with a straight one. I stick a 1 inch gauge block under it and calibrate it at the 2 inch mark.

If I use the fine adjusting knob on the height gauge to slowly drop the finger down until it touches, its quite often tricky to actually determine the point at which it touches, and I guess you could have the same effect when zeroing to the base. You could crank it a thou too far and actually have lifted the front of the height gauge up, or alternatively what you think is touching is actually slightly above base. You loose all feel for the "touch down" point when using the fine adjustment. This isn't just a calibration thing. It would be exactly the same if you were using your height gauge to measure the height of a block and needed to touch down the finger on the top of the block.

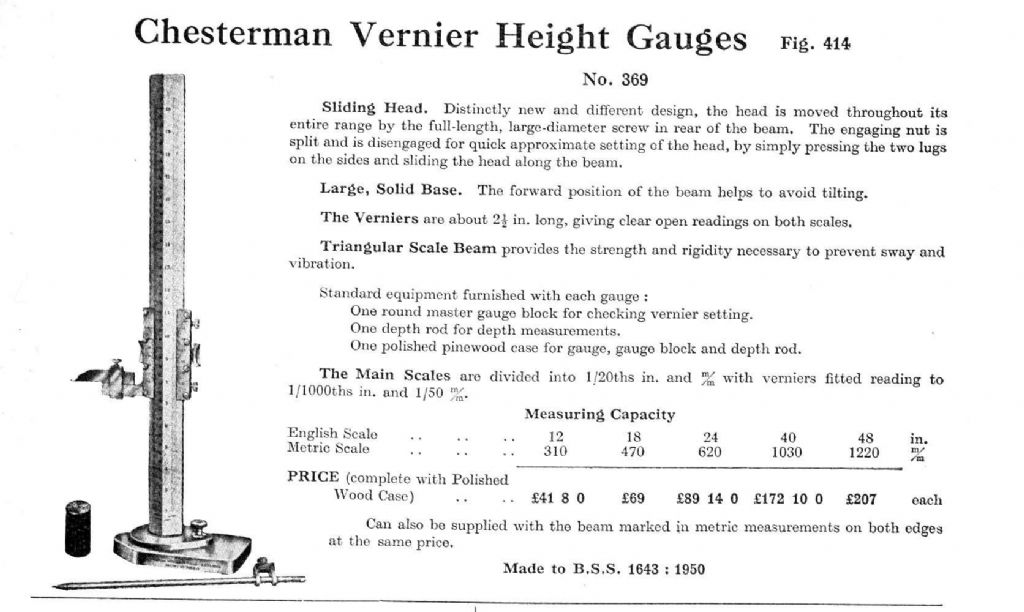

This is on a chesterman height gauge with has coarse adjustment by disengaging the head from the feedscrew and sliding the whole head up and down, or fine adjustment using a knob on the base to spin the feedscrew. If I attempt to touch down onto a gauge block using the coarse adjustment, the head drops back into the nearest thread in the feedscrew which moves the head.

If I get the height gauge close to the right height using coarse adjustment, then press down on the base and use fine adjustment to drop the finger onto the top of the item being measured, I can kindof feel it touch, but not definate enough for it to be repeatable to the thou.

I suppose I could try getting it to what I think is touching, then if I can slide the gauge block in and out from under the finger, but not feel any noticeable up and down play when I try and rattle the gauge block, that would probably work.

I guess its all in the technique.

Do i have a 40 year old gummed up height gauge that has "lost its feel".

My height gauge has been at the back of my tool cupboard since I acquired it. And Ive only just tried to start using it. Can you tell

Graham

Howard Lewis.