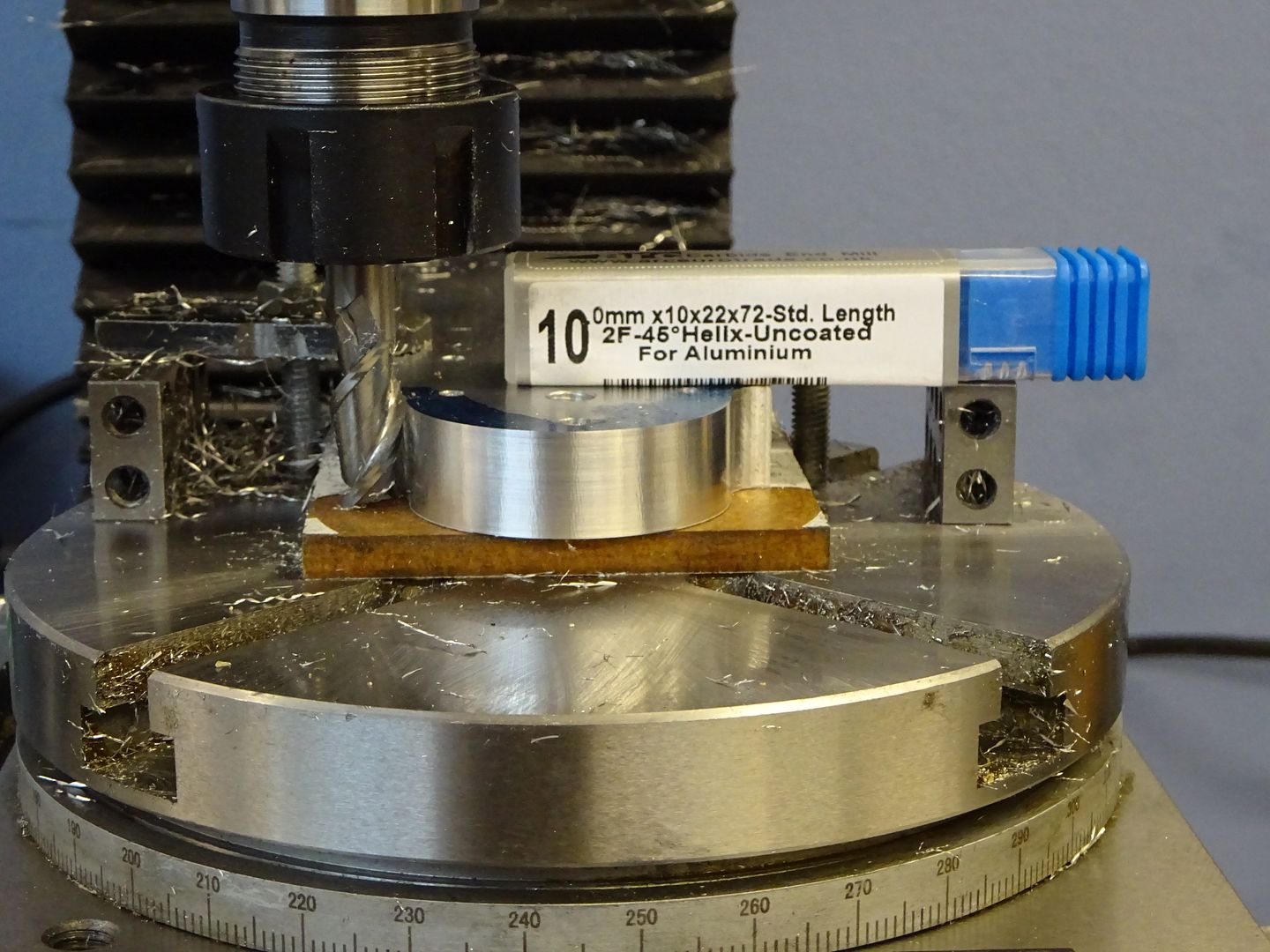

As has been said step one is to get a reliable brand. I tend to buy mid range industrial ones as my machine is a Bridgeport.

Step two is to make best use of what you have bought within the limitations of the machine. My Bridgeport is a monster compared to your X1 but its still only specced for endmills up to 1" diameter!

There is much more to be gained by setting into a proper technique to get longest life than by stumping up the extra ££ for a super duper extra quality cutter costs over decent mid range.

Coatings are generally thermally sensitive and usually need to get hot to work properly. No point in paying the extra if you aren't going to see any real benefit because your machine cannot work them hard enough to heat up. However even if the coating doesn't get into working range the cutter may still last a little longer but this is usually more due to the base cutter being of higher quality than a simple mid range one. If a good maker is going to go to the trouble of coating it makes sense to start with a high quality cutter.

If buying off brand a certain care and feel for prices is needed to avoid the low end cutters dressed up with a pretty coating for showroom appeal. Rather like the pretty TiN coated drill sets in the bargain bin.

Normally too messy for us but decently arranged coolant, either mist or flood, is probably the best way of extending cutter life. On my Bridgeport decent but inexpensive with mist is about the equal of good (mid range industrial) dry for lifetime.

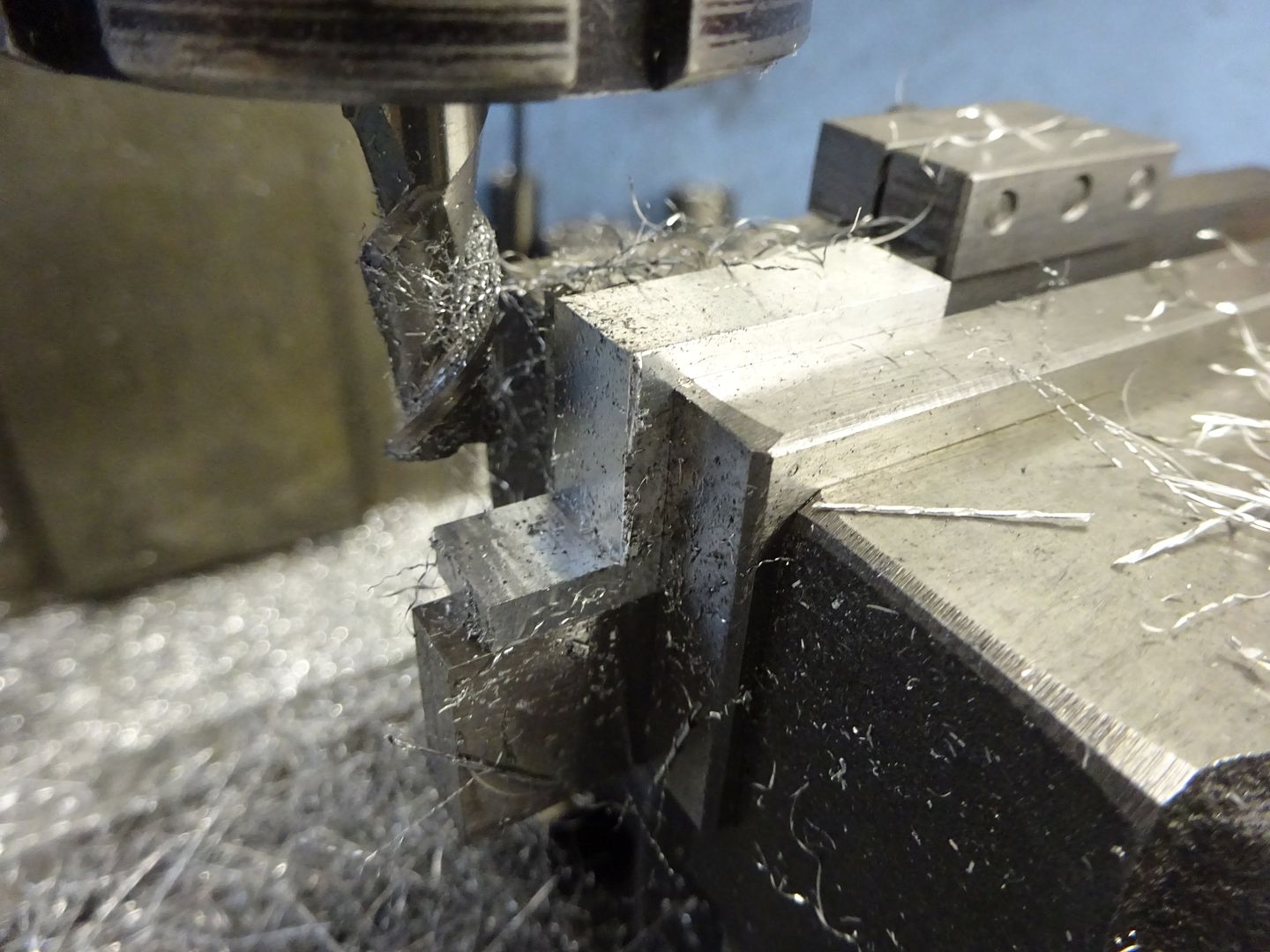

The big neophyte error is babying the cutter with tiny cuts rather than letting it cut. For best results and life you need to get close to book values. Oh and use the sides, book says depth same as diameter at 1/4 diameter width for endmilling and 1/2 diameter depth for slots so get as close as you can given the job and machine specifications. I can just follow the book, you will need to be more circumspect with larger cutters.

Fundamentally the cutter lifetime is defined in number of turns and number of passes. Crudely twice as many passes at half the feed means 1/4 as many jobs per cutter. Keep the chips clear, recutting chips still counts and conditions are unfavourable.

Don't go mad as you are machine stiffness limited but it's well worth sacrificing a cutter or three just to get a good handle on what works for you. When you have found out the best settings, whether by experiment or inadvertently mid job write them down.

The advice against carbide cutters is primarily against the insert kind. Generally the holder diameters are too large and the inserts designed for heavier cuts at higher speeds than your X1 likes. But, as with lathe tooling, there are a fair number of inserts that work fine in lighter machines at well below book speeds and cuts. There are also some that will leave a ploughed field finish if used off book. Experimentation is expensive!

Normal endmills in carbide will be fine. Handle with care as they are very sharp. They don't like vibration which can lead to edge chipping. Given the much greater durability of the sharp edge relative to HSS this is the one time where going light on cuts may be an advantage with a small machine which doesn't have the mass to tamp down vibration.

Carbide shanks are "more slippery" than steel ones so they don't hold as well in collets. Collet needs to be pulled up well. ER are better than Morse or 5C but you should use book torques. Don't even think about bodging one into a drill chuck to save changing the chuck out. It will walk straight out under cut! Learned that the hard way many years ago when I "only wanted a quick counterbore" on a drilled hole. My carbides are weldon flat types.

Clive

PS Sorry for repeating some previous advice. Slow typing. + 1 Andrews recommendation for Cutwel, a very good supplier.

Edited By Clive Foster on 29/03/2022 10:13:58

JasonB.

JasonB.