Hello Nicholas,

When I bought my first mill it only had one tee slot down the centre of the table so I had someone mill two more the same size as the tee nuts for the Myford cross slide. At first it was all a mish mash of BSF and BSW bolts and studding but when I made a new, longer, table for the mill it was time to 'standardise'. Slightly larger tee slots than Myford were milled in and 6mm bolts settled on – 8mm looked too big. Even with the new Amadeal mill with much larger tee slots it's still the same clamping arrangement for as said there's more than sufficient clamping force for anything that I am likely to machine.

Passing info on can be a double edged sword for some can and do see it as preaching where as for many it's helpful and useful. To me though to have that info and not pass it on for others is not an acceptable attribute, even worse is to carp at those that do and yes, unfortunately, there are some who do.

For my sins I'm not an academic, I'm not even time served, but I have spent an awful lot of time machining since my mid thirties and am happy to share the info acquired over that time with any who is interested.

Bill,

my apologies – I missed the significance of the 'vise' so yes, agreed, that could be in situ for a long time without being moved.

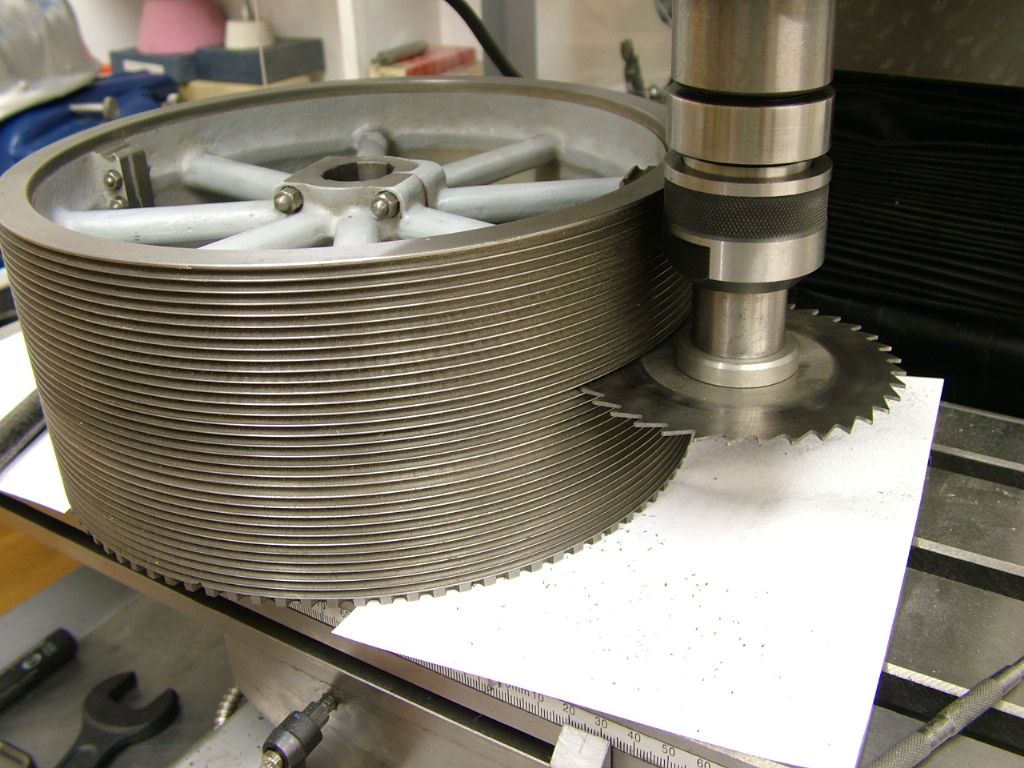

Personally though I can't see the need to place a piece of paper under a milling vice – usually it's a workpiece that that serves best but if the surfaces of mill or vise base are less than ideal then yes it would help. I would think though that the corrosion you describe would be a price to pay over long periods of time

Stevegtr – I assure you this is not a criticism of 'Ade' – I've never seen any of his videos – but more as a result of an observation of the image in the original post.

Peter – why not give it a go, you'll be quite surprised at it's benefit – just one piece of copy paper under an item will considerably improve the grip of a workpiece using the same clamping pressure.

Tug

Colin Heseltine.