How necessary is 3D?

How necessary is 3D?

Home › Forums › CAD – Technical drawing & design › How necessary is 3D?

- This topic has 28 replies, 17 voices, and was last updated 25 August 2015 at 16:06 by

ANDY CAWLEY.

-

AuthorPosts

-

22 August 2015 at 12:34 #21188

Peter G. Shaw

Participant@peterg-shaw7533822 August 2015 at 12:35 #201438Peter G. Shaw

Participant@peterg-shaw75338Hi folks,

On and off, I have been using 2D CAD for something in excess of 12 years. Nothing dramatic, nothing fancy, just a few drawings for my own use and occasional articles in MEW.

I actually have a very old version, and a less old version of the same program. Both are 2D/3D and I've never felt the need for 3D other than for interest, so recently I thought I would try to create a 3D version of a part I have made. Suffice to say that I don't need a 3D version as the 2D version was perfectly adequate.

What I have found though, is that there appears to be a horrendously steep learning curve for this program's 3D capability. I have to an extent been through the (limited) user guide only to find that the objects they show bear no resemblance to what I wish to do – fancy shaped hollow tube with walls the thickness of the line on the screen, goblet, table, house etc. I expect the techniques shown are probably designed to demonstrate the 3D capabilities, but even so, I have found it difficult. In fact, I've so far failed to produce a 3D drawing of the part, but I do still have other methods of getting there to explore. Which brings me to the crunch question. Just what are the advantages of 3D? As someone on another thread said, in general I can visualize what I am trying to do, even though that visualization may be somewhat hazy.

From my point of view, 2D does appear to be adequate. Also, being in my early 70's and hence within easy reach of that perfect lathe in the sky, I do wonder about 3D. Should I spend some of whatever time I have left coming to grips with something I may never need?

Please note, I am not decrying 3D. When all said and done, there have been some impressive colour 3D photos on both the forum and in the magazine. Which is something else I would have to get to grips with, ie using colour.

Over to you.

Peter G. Shaw

22 August 2015 at 13:28 #201441 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattLife would be flat without it.

Neil

22 August 2015 at 13:37 #201442 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattMore seriously, converting a 2D drawing to 3D isn't the point.

My tech drawing instruction is far enough in the past that I was able to go straight to 3D. the design process is almost completely different, it's much more like making a real part – you cut bits away and add bits on, although you do make reference to various XY views to check alignments and clearances (it's easy to make two parts and think they are nicely aligned and then realise they are far apart or overlapping when you turn the model! – the answer is usually just a shift in one dimension).

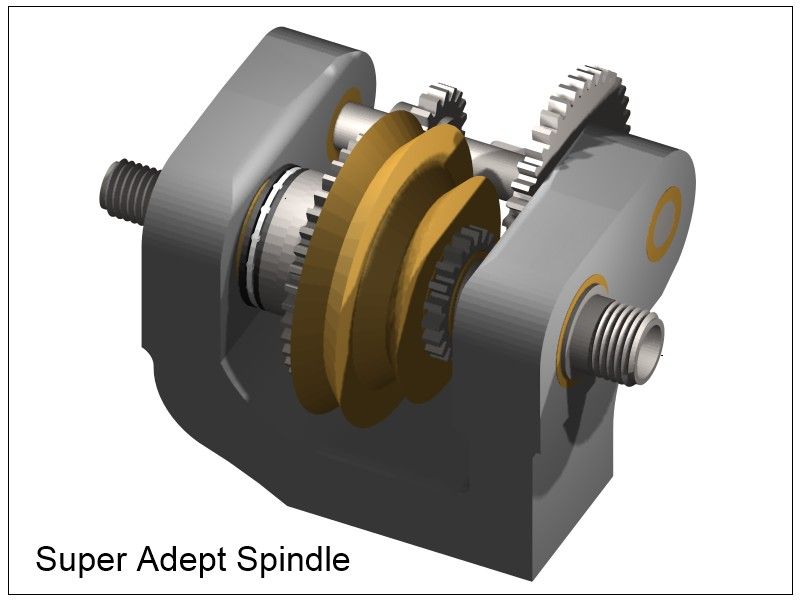

The exception I have found is when creating 'solids of revolution' such as a the hollow spindle below – I drew it as a 2D half-section then rotated it to get the 3d part. Simpler things like bushes are more easily made by extruding two overlapping cylinders, joining them, then subtracting a shaft through the middle.

The 'casting' part of the item below would have been hard (for me) to design in 2D and convert, and almost impossible if I had drawn it exactly as it turned out.

Neil

22 August 2015 at 13:37 #201443Muzzer

Participant@muzzerHi Peter

You probably don't need to choose and install a 3D program to get a feel for what is involved if you go to Youtube and watch a few videos of people in action. For instance, NYCCNC has some interesting vids – here's one on Fusion 360 which is free. There are loads of tutorials and introductory videos on Youtube, many by the manufacturers and "resellers" and also many by enthusiasts.

Try a few out once you've seen the videos. If you don't like any of the free ones (Fusion, Onshape, Designspark etc), there are 30 day trials for many others.

Incidentally, I'd be sceptical about a program that was 2D and is now 3D. The way "true" 3D programs work is quite different and probably more intuitive.

Murray

22 August 2015 at 13:42 #201445John McNamara

Participant@johnmcnamara74883Hello Peter.

The steep learning curve to 3D is not as steep as you may think. I don't know what software you are using but most are pretty similar once you dig into their operation. There are dozens of similar programs; you draw a line or object to a specific length then edit the line or object size if you need to change it. Many Cad programs work this way. I use AutoCAD.

to make 3D objects you first create an outline by drawing a basic plan of the object base or face, you then extrude the shape to a specific height. creating a crude extrusion.

You can create as many extruded objects as you like, and these objects can be joined to other objects or "Subtracted" from other objects. If you think of this process as a machining process you will soon get the hang of it, Imagine you are drilling holes, (By subtracting an extruded cylinder from another block) or milling out a pocket (By subtracting a rectangular object). You may also wish to join objects think of this as welding, once joined you end up with a single part. In AutoCAD these are called Boolean operations.

You can also revolve a line around a central axis creating a stepped shaft for example. Does the shaft need cross drilling? no problem just subtract a cylinder in the right place.

There are other processes you can perform on your objects for example filleting or chamfering internal or external corners on your 3D object. Not really that different to workshop practice.

Here is a link to a few videos on solid modelling.

Once I started to think of solid modelling as cad machining, I found the learning curve a lot less steep.

Yes there are many commands available in a CAD package however you do not need to learn them all at once. For engineering design you only need a couple of dozen to start with, As you will see in the videos. Once you are fluent with the basics you can extend your knowledge at your own pace learning new commands as you need them.

If you have been working with the one program for the past 12 years that would be a good place to start. You already know your way around the program, a great help.

Regards

JohnPS:

There is a second group of CAD programs that work a little differently. Solidworks is a well known example. These programs have parameter driven sketching. You draw a line then enter dimensions to define its properties directly. The solid model editing is really the same as above you just go about it in a slightly different way.Edited By John McNamara on 22/08/2015 13:53:55

22 August 2015 at 14:46 #201451David Jupp

Participant@davidjupp51506Peter,

In addition to points made by others. 3D is great for checking interferences or clashes in assemblies at the design stage, or even checking movement of mechanisms. It will estimate part/assembly weight for you (if you enter correct material density). Changes tend to be easy – and the derived 2D views update automatically to reflect the change. You can also download lots of 3D content from the internet to incorporate into your designs – so for many bought in items, you don't have to spend time drawing them yourself.

Of course there is nothing wrong with using 2D only.

EDIT – I'd also add that (particularly with the use of shaded and isometric views) – 3D CAD can help a lot in conveying your design ideas to those who either aren't familiar with 2D drafting, or just have trouble visualising the finished item.

You will get much faster with practice.

Edited By David Jupp on 22/08/2015 14:52:38

22 August 2015 at 15:01 #201454IanT

Participant@iantI've 'dabbled' with 3D Peter but discovered it seems to need a very different thought process to the way I normally approach a (2D) drawing. You have to really figure out (imagine) the various major 'blocks' involved and then draw, extrude and join them together. I did manage to draw some simple 3D constructions in the end but it took me a while and I wasn't too sure what I'd really gained in the process to be honest. Of course, I was on that possibly steep learning curve at the time, so it's not an entirely fair judgement. I was also using my existing CAD (TC15) which may not be the ideal tool for 3D (although others seem to have mastered 3D with it).

Most of my drawings are generally straight forward in nature and (these days) I can do them fairly quickly, at least in 2D. I do use my CAD interactively to work out some areas of a design (hole positions, clearances, alignments and such things). Perhaps with more complicated designs than mine are, 3D would be useful to check similar kinds of detail.

However, to answer your question, whist 3D seems to be very useful to some, personally I haven't found sufficient motivation to make the transition to 3D thus far. If I was using CNC (or 3D Print) this might be different of course – but I'm not – and that may be a key difference in the way folk view this particular issue.

Regards,

IanT

22 August 2015 at 15:47 #201459Ajohnw

Participant@ajohnw51620I really wonder about the usefulness of 3D in the model engineering type world. In the professional world it tends to be more a visualisation tool that allows the customer or the management to see what they are going to get without actually making it. I'd guess it has put a fair number of a different type of model engineer out of business but in some fields models are still made – at great cost as well. That is part down to the limitations of PC screens and in extremely representative forms the power of the machines that are needed.

I spent several years on a drawing board in several different fields and from that I can see that some people do have problems visualising the objects that will result from 2D drawings. I find it hard to understand why in most cases. One job I was given was laying out a rather complicated "automated" canteen, nobody serving, all machines and the head man at the time wanted to know what it would look like so I did a 3D view from his eye level from a particular part of the room. No cad. all done on a drawing board.

I can see the point in something like that particular exercise but not Neil's 3D head. A GA and detail drawings would give far more detail. It could be an alternative to a GA if I could drag the viewing angle around with a mouse etc but it doesn't give any indication of actual sizes / enough information to actually make one.

More recently I've also watched designers of various types working with cad. One thing is pretty clear given a library of standard parts it's pretty quick and effective. When parts have to be created it most definitely isn't. These are people using it 8 hours a day not novices. Having seen the final results on one project I really have to wonder. A director said I want to see it more brick like, what ever that means. Several people quietly produced amazing 3D bricks to cheer themselves up. In the end after all of the messing about was complete a model was made and yet more changes introduced. A singleproduct running at around £25M / year. Development time is expensive and 3D increased the time significantly.

On the other hand some very reasonably priced versions of 3D Studio were available some years ago. I used to spend hours and hours PLAYING with it. That's fun so as far as 3D roughly representative cad why not just for the fun of it.

I've also seen an instructional video one on package – all of the 3D sizes were read off 2D drawings that had been prepared previously. It was a complicated gear pump. Some parts were fairly trivial to produce in 3D, some were not.

John

–

Edited By John W1 on 22/08/2015 15:49:48

22 August 2015 at 16:30 #201462 JasonBModerator@jasonb

JasonBModerator@jasonbI tried several 2D packages and never really got on with them always returning to my trusty drawing board but a couple of years ago decided to give 3D a try and got on with that straight away (Alibre) Originally I only bought it for my hobby model engineering but now use it a lot for work as well

As David says a 3D image is a lot easier for many people without a technical background to understand and easy enough to take a few screen shots of the item viewed from different angles or better still send them an interactive pdf so they can move the item to view from different angles, zoom in etc. Its also just a couple of clicks to show the same thing with a door open or draws pulled out.

The same applies in the ME field, take a look through some of my posts or my album "sketches" many a time a 3D image or two can convey what would take ages to describe or show someone how a part should look if they can't understand the 2D drawings. I think this type of visualisation will help bring more people into the hobby who may not have studied technical drawing or engineering at school. Its also very easy to add a 3D thumbnail of the part to the 2D drawing which again can only be a help to those who have a job understanding drawings and can help with confusing from 1st or 3rd angle projection.

The ease at which a part can be altered and carried through to any assemblies etc is also very useful and would save a lot of time compared to having to redraw a perspective or isometric drawing.

As Neil hinted once you have assembled a few parts its very handy to be able to hold your mouse over the end of a crankshaft or spindle and move in a circular mation you can then watch to see if that conrod, cross head or big end clash with any other parts, can't see that easily being done with 2D

Another usful aspect is being able to overlay parts and alter their transparency. I have found this useful when making patterns, the semi transparent pattern drawing can be overlaid on the finished item to check you have enough machining allowances, shrinkage etc. Then if you want to 3D print the pattern thats only a click or two away.

Is it needed – maybe not, is it useful definately.

J

22 August 2015 at 16:41 #201463David Jupp

Participant@davidjupp51506Posted by John W1 on 22/08/2015 15:47:03:I can see the point in something like that particular exercise but not Neil's 3D head. A GA and detail drawings would give far more detail. It could be an alternative to a GA if I could drag the viewing angle around with a mouse etc but it doesn't give any indication of actual sizes / enough information to actually make one.

The GA and detail drawings are produced from the 3D model with very little effort (the projections are automatic – as often are section views). The model inherently includes sizes (everything is typically modelled at full size) and the CAD system has measurement tools to allow easy checking of any resulting dimension. These sizes drive any dimensions that you choose to include in the 2D projections.

You can drag the viewing angle round, zoom in/out, hide parts or make them semi-transparent to 'get at' things.

22 August 2015 at 16:57 #201465Phil P

Participant@philpSpeaking as someone who used Autocad 2D every day for 15 years, and now Solidworks 3D for the last 10 years.

If someone told me I had to go back to 2D I would just give up completely, there is no comparison, going onto 3D was like a breath of fresh air and makes my job as a designer of bespoke machinery so much easier.

You need a totally different approach to learning 3D, in fact someone who has never used 2D will probably learn 3D quicker.

Once the models are done, the drawings are just a few mouse clicks away, if any changes to the models are needed the drawings will update automatically as well.

Oh and YES, I do all my model engineering drawings with it as well, even if there is a published design I want to use, I model it in 3D to make sure it will all work out correctly, I only have myself to blame then.

Phil

Edited By Phil P on 22/08/2015 16:59:03

22 August 2015 at 18:17 #201479Bowber

Participant@bowber£D has a lot of uses and you generally get less mistakes in your drawings created from a 3D object.

In industry it's also good to add the ISO view into the drawings so the manufacturer has a good idea of how the part is meant to look.

However for hobby use it's not as relevant unless your using 3 axis CNC with raster machining (each cut is a slice from the model) and 2D is usually more than adequate.

Even with CNC I find myself doing most of the code by hand or with the wizards in Mach3

It can help some people visualize how they would make a part but I usually have the machining sequence sorted in my head the second I look at the part.Steve

22 August 2015 at 18:53 #201484 Neil WyattModerator@neilwyattPosted by John W1 on 22/08/2015 15:47:03:

Neil WyattModerator@neilwyattPosted by John W1 on 22/08/2015 15:47:03:I can see the point in something like that particular exercise but not Neil's 3D head. A GA and detail drawings would give far more detail. It could be an alternative to a GA if I could drag the viewing angle around with a mouse etc but it doesn't give any indication of actual sizes / enough information to actually make one.

As David said, I can bring up a 2D from any direction, or an isometric, with a couple of clicks, or even set up permanent 'viewports' on other tabs.

I think Jason is right, if you come from a 'building' background then 3D is more intuitive, if you have a drawing background, you will naturally be more used to working in and reading 2d.

Neil

22 August 2015 at 19:03 #201485Enough!

Participant@enough"How necessary is 3D?"

The answer of course is "it's not". The world got along perfectly happily before 3D CAD. Things got made, life went on. I use 3D all the time but I could get along without it – I just wouldn't want to.

It's rather like adding a DRO to a mill …. it isn't necessary but most people who go that route will tell you they couldn't go back.

Or the cell-phone. Again not necessary but most people wouldn't give them up. In this case I have one but but frankly the disadvantages (to me) of other peoples' phones far outweigh the advantages (to me) of my phone. So in this case, I'd be more than happy if the world went back.

You can't put the Genie back in the bottle but that doesn't mean that you have to subscribe. Nor should you feel guilty or out-of-step if you don't. If what you are doing now meets your needs and you are happy with it – more power to you.

23 August 2015 at 01:31 #201505Paul Lousick

Participant@paullousick591163D CAD is not necessary. It is only another tool that makes it easier and often faster to manufacture something. Most things that are done in 3D could be done with a pencil and paper. But would you prefer to use a slide rule or log tables instead of a calculator or a computer ?

I started my career on a drawing board. Production increased significantly when 2D CAD become available and then again with 3D. Learning 3D in the early days was a long learning curve and to become proficient to create drawings to a comparable standard to ones which were previously created by hand could take 2 – 3 months of training and practice. Modern software is much easier and faster to master. I started with Autocad version 9, then ProEngineer, then Solidworks.

Most 3D models are created by sketching a 2D shape (x and y direction) on a plane or surface and then extruded in the z direction to give it thickness. (eg. To create a part 100 x 200 x 20. Draw a rectangle 100 x 200 and then extrude it 20 in the z direction) With conventional CAD software, the size of the model is controlled by sketching the x,y,z lengths to scale. The size of the model is changed by modifying the sketch. The dimensions for the model are a reference of what was sketched.

Advanced 3D CAD produces Paramertic models where the size of the model is controlled by the dimensions. They are created in a similar way but the size of the model is controlled by the dimensions. eg. To change the length from 200 to 300, you click on the dimension and the model changes. Much quicker !

The 3D models are used as the reference for producing 2D drawings. Projected views, sections, details are quickly made. The models are excellent for checking the compatibility with mating parts and reduces the drawing checking time. If it fits in the model it should fit together when manufactured (if it has been modeled correctly in the first place).

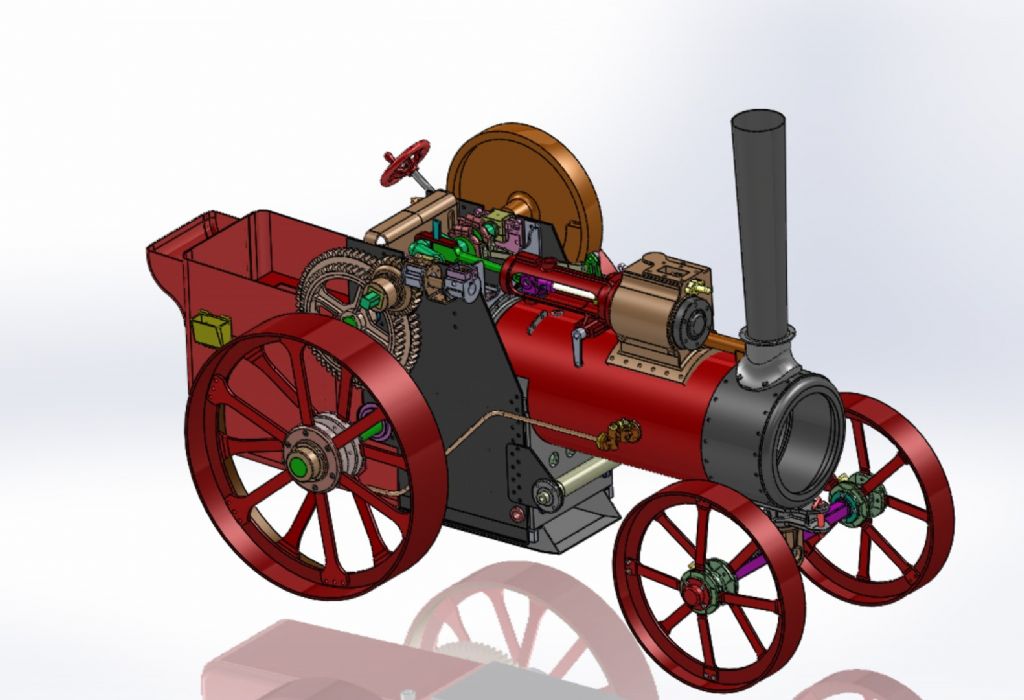

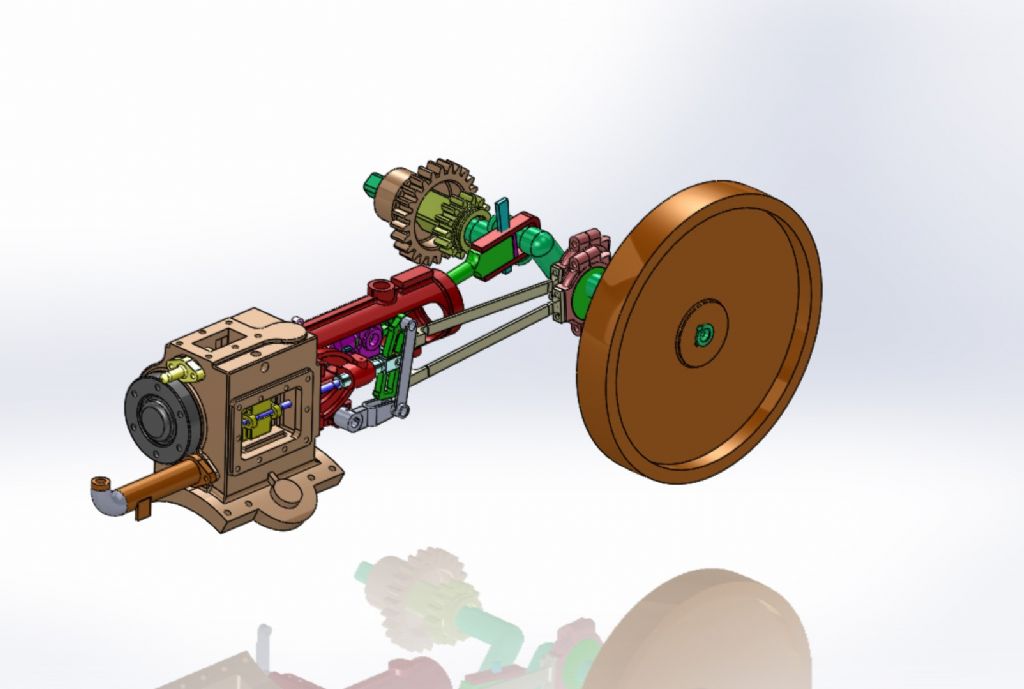

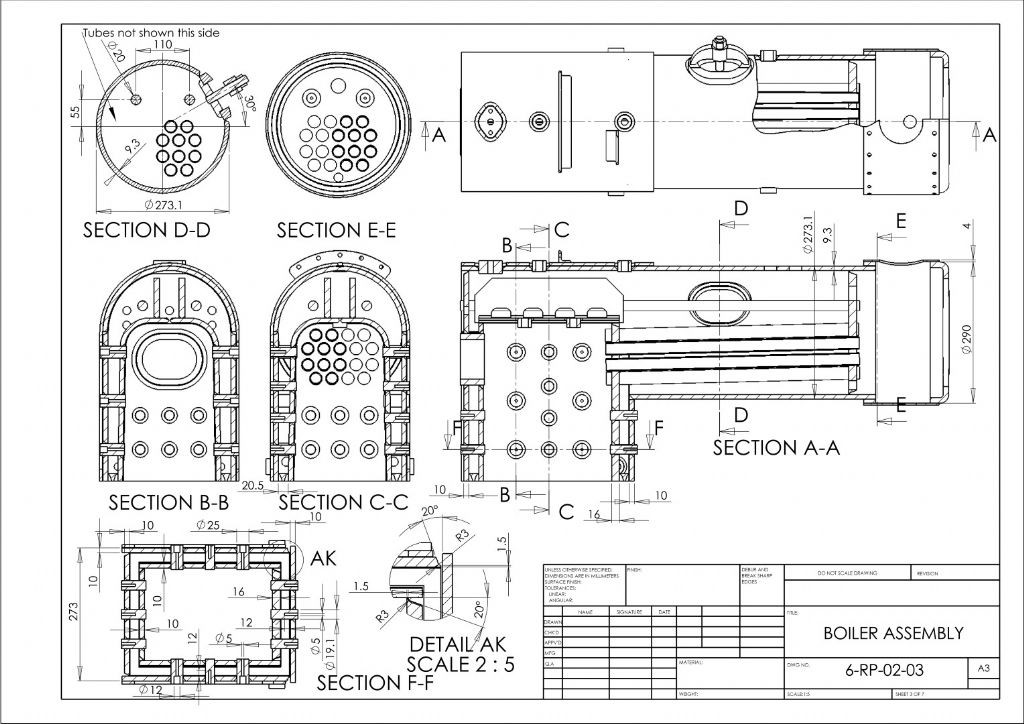

I am building a model steam traction engine from a set of drawings which I purchased. But these drawings are not 100% correct and lack a lot of detail. Also the size of available material is not available and the drawings have to be modified. Therefore I have modeled the engine in 3D before I start machining. There are hundreds of parts which need changing. Much easier and cheaper to fix a problem in the computer model than in the workshop.

The 3D model allows me to check how everything goes together. The model can also be animated to show problems. I can rotate the flywheel and see the motion of the piston and connecting rods and check the position of the slide valve to see where it opens and closes thru the cycle. The drawings are linked to the model and if the model is modified, the drawings are automatically updated and therefore never out of date. 3D models also contain heaps of other information such as its volume, mass, centre of gravity and can be used for determining the stresses within the parts. 2D drawings can be used for profile cutting parts and 3D for creating casting molds and sent to 3D printers.

Paul.

Edited By Paul Lousick on 23/08/2015 01:34:22

23 August 2015 at 08:51 #201511John McNamara

Participant@johnmcnamara74883Hi All

It surprising to me that 3D CAD has garnered little support in this thread.

Yes it takes a perseverance to become comfortable with it. You don't have to run the Olympic marathon but it is not the 100 yard dash either, you have to pace yourself and learn. A couple of hours a day maybe 50 hours total and you will be over the hill. Many metalworking projects take a lot longer. Learning Cad is ideal when the weather is too bad to work in the workshop.

No matter what program you use there will be lots of tutorials and support forums on the net to support it.

So what are the benefits? Below are just a few.

To me number one is your designs will be better. Do I need to say more?Being able to "see" the relationships between the various components that make up your machine design allows you to refine each component minimising wasted material and optimising strength.

Checking for interference between sliding, rotating, or fixed parts is easy.

Being able to rotate and view the model from any angle allows you to consider the aesthetics of your design more completely, 2D views cannot do this.

The ergonomics, the way the design interacts with people can be checked, as can the safety features needed to reduce the risk of injury to an operator.

Design is an iterative process, you are constantly reviewing your work, each time you make a change to a part it may affect all the other parts that it interacts with, 3D Cad allows you to make those changes in the minimum of time. Documentation will be automatically updated.

Documentation: A major benefit once your model is completed it can be printed at any view angle, individual parts, or assemblies, exploded drawings are also easy, as are cut through sections, and x-ray views. all without redrawing an object.

In my youth I used to like cross country running, At the beginning of a run it is easy to spurt and then run out of wind, you have to pace yourself at the start and get into a comfortable stride, once settled in you can reach a point where the run becomes a lot easier, even effortless, taking you to an exhilarating finish.

3D Cad is a journey worth the effort.

Regards

John23 August 2015 at 11:12 #201535Mark C

Participant@markcAs a professional designer and user of Solidworks (special purpose machines like Phil P? ) I have sometimes commented on here about CAD but I wonder how much use my comments are to the other readers. What I mean is; the comments I make are related to my experience of using 3D CAD which is far removed from a spot of laying out for a model engine – you might think. In reality, we all want accurate information tailored to the situation.

3D does this very well, the differences lie in how you get there using 3D. As mentioned above the approach is a little different to drawing in 2D on paper or CAD but the process is the same. You still have to have an idea as to what you want to draw and then you simply do the "fag packet" sketching on the computer instead of scraps of paper etc. The computer captures all the "sketch" data and uses it to create the solid model. What has not been mentioned – possibly as it is not available in the "cheaper" CAD systems – is that the assembled item (engine? ) will have the important features fixed (constrained) in relation to the main arrangement (Master GA) and then subordinate parts are referenced to that. This is known as "in context" in Soplidworks and allows me to make important features "propagate" through the model. This means that if I draw an engine with a 10mm crank pin and 20mm cylinder and then decide I really want 12mm crank and 20mm bore, all I do is change the master part and all the referenced "in context" details change with it. This is especially true of hole locations and such and given that the 2D drawings are linked they are always "current". This means that you will always be able to assemble the thing later (assuming you dealt with tolerances and machine errors first! ).

Whether you would want to do this or not is entirely a personal choice but I like to know that when I make something – it is going to fit/work so it is my default method of working.

Learning the system is easy (for Solidworks) as it is THE most intuitive system you will ever use but also very expensive so you might be forced to use something else. If the Autocad thing is even half as good then it should be relatively easy to learn but I will not use their products for a number of commercial reasons.

Mark

PS. Happy to elaborate if it helps, just ask!

23 August 2015 at 21:01 #201610Peter G. Shaw

Participant@peterg-shaw75338Hi folks,

Thanks for all the replies.

Ok, it seems that I have approached this from entirely the wrong angle (sorry about that!), something which has been confirmed by the DesignCad forum as well. Which means that I still have serious doubts about its necessity from my personal point of view, ie given my age, do I have sufficient time to become reasonably au fait with it; given what I do (not much); do I need to do it in 3D; and so on. As it happens, most of what I do is replacement, copying, minor modifications where there is plenty of space and hence no problems with fitting it all in, etc. Indeed at the moment I can only think of one possible project where it might come in useful.

I deliberately did not mention which program I was using because I didn't want to influence anyone's thoughts, but have done now – DesignCad 2000 & DesignCad 3D Max v 17.2. Both programs claim to be able to be used for 3D modelling. Whether they can be used for dimensioning off the 3D models as someone above has suggested, I do not know – it's possible that the latest versions (v. 25) may well do this but taking my actual requirements into consideration, as distinct from what I would like, plus a rather important fact that I am using these programs via Linux and not Windows and there are a few problems with this, I doubt very much that I will be upgrading anytime soon. People also mention SketchUp. I have just looked at the website and it would appear to be available only for Windows and Mac which would mean that for Linux use, I would have to get it to work via Wine, and there's no guarantee that it will work, Therefore, at least for the present I will be remaining with what I have already got.

Anyway, thanks again for all the comments, and yes I know what I've written above sounds negative, but now I do indeed need to think again.

Peter G. Shaw

23 August 2015 at 21:32 #201616John Stevenson 1

Participant@johnstevenson1Posted by Peter G. Shaw on 23/08/2015 21:01:13:Hi folks,

Thanks for all the replies.

Ok, it seems that I have approached this from entirely the wrong angle (sorry about that!), something which has been confirmed by the DesignCad forum as well. Which means that I still have serious doubts about its necessity from my personal point of view, ie given my age, do I have sufficient time to become reasonably au fait with it; given what I do (not much); do I need to do it in 3D; and so on. As it happens, most of what I do is replacement, copying, minor modifications where there is plenty of space and hence no problems with fitting it all in, etc. Indeed at the moment I can only think of one possible project where it might come in useful.

Peter G. Shaw

Peter I think you have summed this up well for a lot of readers on this forum.

Basically there are two groups that run together and can be sub divided various combinations, – roughly

One group is age and the other is professional and non professional.

Now take the two extremes, young and professional. These take to 3D like a duck to waters, they have the time, mental agility and more so the effort to achieve knowing that this will make life easier for them in the future.

Now take the opposite end, wrinkly and non professional. Now if they have any CAD experience it will be 2D and probably on old programs that in even the modern 2D world are hard to work. Throw in they do not have the time to learn a very advanced program and take it real slow, in both learning and time applied.

The result is that when they go back to where they had left off they have forgotten how it works and then because it won't do what you want, then it leads to frustration.

There is no easy way out, time has to be applied but they probably wont allocate that time or resent it for what is basically a hobby but a hobby this is making things as opposed to drawing things.

So is it necessary for the hobby? No it is not necessary but neither is a DRO on the mill. However if you can afford a DRO on the mill and this is not just the price of the DRO which is equal to a 3D program, but you have to take into account fitting it and learning to use it which is equal to learning to use 3D CAD although it takes longer.

So if you now have the DRO, you won't go back but if you could have 3D CAD for the same outlay of time you would do it and not go back either.

The stumbling block is the steep learning curve and the time needed to learn it and lets be honest here, as you get older time gets shorter as does the ability to learn things fast.

Edited By John Stevenson on 23/08/2015 21:34:47

23 August 2015 at 21:49 #201619 Boiler BriParticipant@boilerbri

Boiler BriParticipant@boilerbriI am in there with Phil P, it is a fantastic tool, far better than any 2d package. Machine development is far easier when you can see behind things. 😊

Brian

23 August 2015 at 22:01 #201620Mark C

Participant@markcJohn, Peter, I suspect that the amount you pay for the software also plays a big role – you aren't likely to be using Solidworks anytime soon if you only have a few hundred quid to spend, i don't know about the Fusion 360 thing. In the case of Solidworks, using it is very very simple as long as you don't want to do fancy stuff like surface generation or complex curves (helical gears…. ). You pick where you want your sketch to go and everything else tends to follow intuitively. It will flash up the lines pallet and you select pen tool, you then click the start point (akin to putting your pen on the paper) and start to draw. It will initially draw a straight line from the starting point but will automatically make it horizontal or vertical as long as you are close, if you want curves from then on you just move the mouse in a curved direction from the last point and it will generate a tangent curve accordingly. when you move near any intersections (ends, midpoints etc) it will snap to them and close the sketch. The whole idea is to leave you thinking about what you are drawing without messing about looking for commands and buttons. Once you are done the rest follows seamlessly. It's a shame it is so expensive as it would surprise a lot of wrinklies by how quick they could learn it, it really is the easiest way to draw and see stuff you can imagine. Even for simple mods where there is loads of space!

Mark

23 August 2015 at 22:05 #201621V8Eng

Participant@v8engPosted by John Stevenson on 23/08/2015 21:32:17The stumbling block is the steep learning curve and the time needed to learn it and lets be honest here, as you get older time gets shorter as does the ability to learn things fast.

Edited By John Stevenson on 23/08/2015 21:34:47

I blame that the six hour days myself, they make the weeks ever so short!

Edited By V8Eng on 23/08/2015 22:08:11

23 August 2015 at 22:15 #201622Phil P

Participant@philpI f you get profficent on 3D CAD you might actually give up making things in metal altogether.

There is a real feeling of satisfaction when you have designed and 3D modeled a Corliss valve mill engine or a traction engine, and you can turn the flywheel on the screen and watch all the valve gear working etc.

Phil

23 August 2015 at 23:34 #201629John Stevenson 1

Participant@johnstevenson1Phil,

You are not wrong there. I did know a guy in an old folks home who was 'building' a full sized loco in Alibre.

He's lost his workshop and the ability to use the machines but did this for about 4 hours a day to keep himself mentally active.

Unfortunately he's long dead now thru old age but it shows an insight into how you can change and adapt.

Mark C.

In all fairness anyone who has overcome the hurdles of learning a system soon forget the hurdles and "It's not hard " is a frequently spoken phrase when actually when you are stood at the bottom looking up, it is hard.

Long short is I reckon you need 20 to 30 hours and then it does become easy. However it's that commitment to the 20 or 30 hours. If you are employed it's only half a week or so, depends if you carry on at night but taken as the odd hour plus playing catchup from forgetting where you got or going back to rectify mistakes that 30 hours can be a year.

Another thing is people learn different ways. Some can learn from books, some need to be shown.

Many tutorials don't follow the program, how many times have you read click the icon that looks like a gear only to find no icon where it's supposed to be and also no clue where it should be. When what they shold say is open the properties toolbar and click the gear icon.

Because they know the program they assume everyone else does.

Not insurmountable but for some it's the last straw, they have spents a week at nights and not managed to do the first tutorial.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Diving in to ATC?

Started by:

Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 4

- 12

-

21 July 2025 at 21:32

Steve355

-

Woodward/Wilding Gearless clock

Started by:

smf in: Clocks and Scientific Instruments

- 3

- 3

-

21 July 2025 at 21:30

Chris Raynerd 2

-

Adding a quill lock to a drill press

Started by:

beeza650 in: Manual machine tools

- 4

- 9

-

21 July 2025 at 21:15

not done it yet

-

Model Engine running just off a naked flame

Started by:

Blue Heeler

in: Stationary engines

Blue Heeler

in: Stationary engines

- 6

- 19

-

21 July 2025 at 21:14

grubscrew

-

Redwing Cylinder head

Started by:

Durhambuilder in: I/C Engines

- 3

- 5

-

21 July 2025 at 21:07

grubscrew

-

Pipe bending by hand versus pipe bending tools

Started by:

Greensands in: Workshop Tools and Tooling

- 3

- 3

-

21 July 2025 at 21:06

bernard towers

-

Arc Euro Trade Ltd.

Started by:

Ketan Swali in: General Questions

- 20

- 20

-

21 July 2025 at 21:03

KEITH BEAUMONT

KEITH BEAUMONT

-

Lidl castors

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 6

- 7

-

21 July 2025 at 21:00

bernard towers

-

Amadeal lathes – Any good??

1

2

Started by:

Tim Sallows in: Workshop Tools and Tooling

- 16

- 29

-

21 July 2025 at 19:16

JasonB

JasonB

-

Issue 4767 and links

Started by:

Andy Stopford in: Model Engineer & Workshop

- 2

- 2

-

21 July 2025 at 19:14

JasonB

JasonB

-

Round Bar Bender

Started by:

Trevor Howley in: Workshop Tools and Tooling

- 1

- 1

-

21 July 2025 at 18:46

Trevor Howley

-

My vise isn’t at 90 degrees

Started by:

moonman in: Beginners questions

- 15

- 24

-

21 July 2025 at 15:41

JasonB

JasonB

-

5 inch gauge Stirling single

Started by:

Michael Callaghan in: Locomotives

- 5

- 7

-

21 July 2025 at 15:37

Michael Callaghan

-

Hopeless…Alibre Ass

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 6

- 21

-

21 July 2025 at 14:40

blowlamp

-

Edward Thomas excessive wheel slip

Started by:

Ian R in: Locomotives

- 3

- 4

-

21 July 2025 at 14:11

Ian R

-

Hofmann Rollers

Started by:

Martin Kyte in: General Questions

- 11

- 18

-

21 July 2025 at 13:07

DC31k

-

Herbert B drill information?

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 4

- 12

-

21 July 2025 at 12:45

Michael Gilligan

Michael Gilligan

-

What’s in the archive?

Started by:

Michael Callaghan in: General Questions

- 2

- 3

-

21 July 2025 at 12:36

Michael Callaghan

-

Myford S7 VFD problem

1

2

Started by:

Glyn Davies in: Manual machine tools

- 21

- 38

-

21 July 2025 at 10:36

Glyn Davies

-

Model Engineer Magazine Collection

Started by:

mfengine1 in: Books

- 9

- 12

-

21 July 2025 at 09:22

Norman Blackburn 1

-

Panorama : Fighting Cyber Criminals

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 2

- 2

-

21 July 2025 at 09:20

Nigel Graham 2

-

What Did You Do Today 2025

1

2

…

8

9

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 202

-

20 July 2025 at 21:39

Dalboy

-

Polishing compounds for stainless steel (mild abrasives))

Started by:

Simon Williams 3 in: Beginners questions

- 13

- 14

-

20 July 2025 at 20:02

Russell Eberhardt

Russell Eberhardt

-

Bad design, or am I missing something?

Started by:

half whit in: Beginners questions

- 5

- 7

-

20 July 2025 at 19:16

Julie Ann

Julie Ann

-

Mistry dividing attachment

1

2

Started by:

Brian Merrifield in: Workshop Tools and Tooling

- 17

- 42

-

20 July 2025 at 18:43

Tony Jeffree

Tony Jeffree

-

Diving in to ATC?

-