Evening all

So armed with the above information I have had a go at hobbing a worm wheel.

Began with grinding a 20degree pressure angle single point tool(done on the little d bit grinder takes a bit of faffing about the get the clearence angles!);

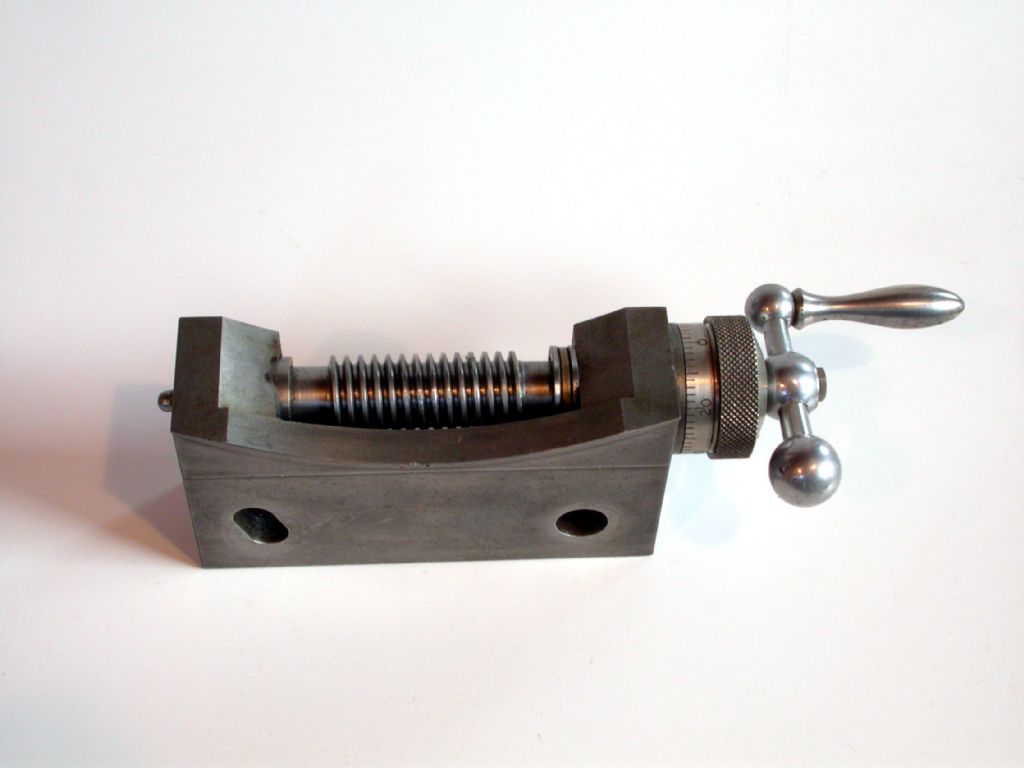

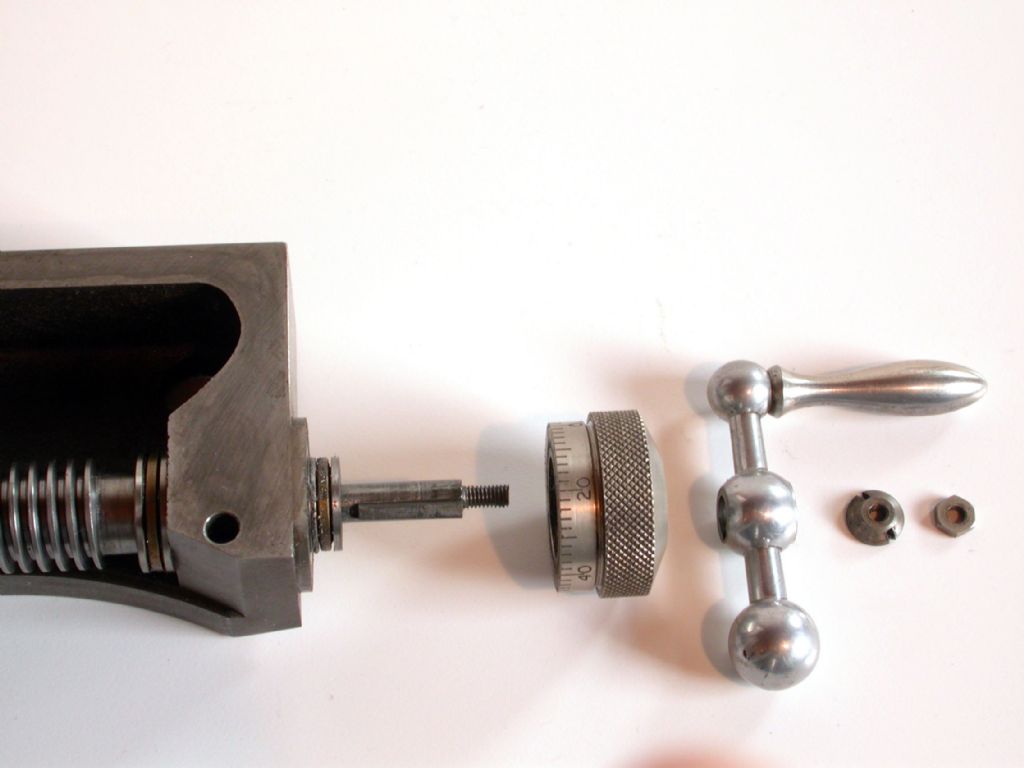

Then I set the lathe the cut the hob, 64dp which meant swapping the input gear for a 33t. The hob screwcut, then some cutting edges formed with a slitting saw. Couldn't find a piece of 8mm silver steel so I used a piece of printer rod, I haven't harden it as it was only a test;

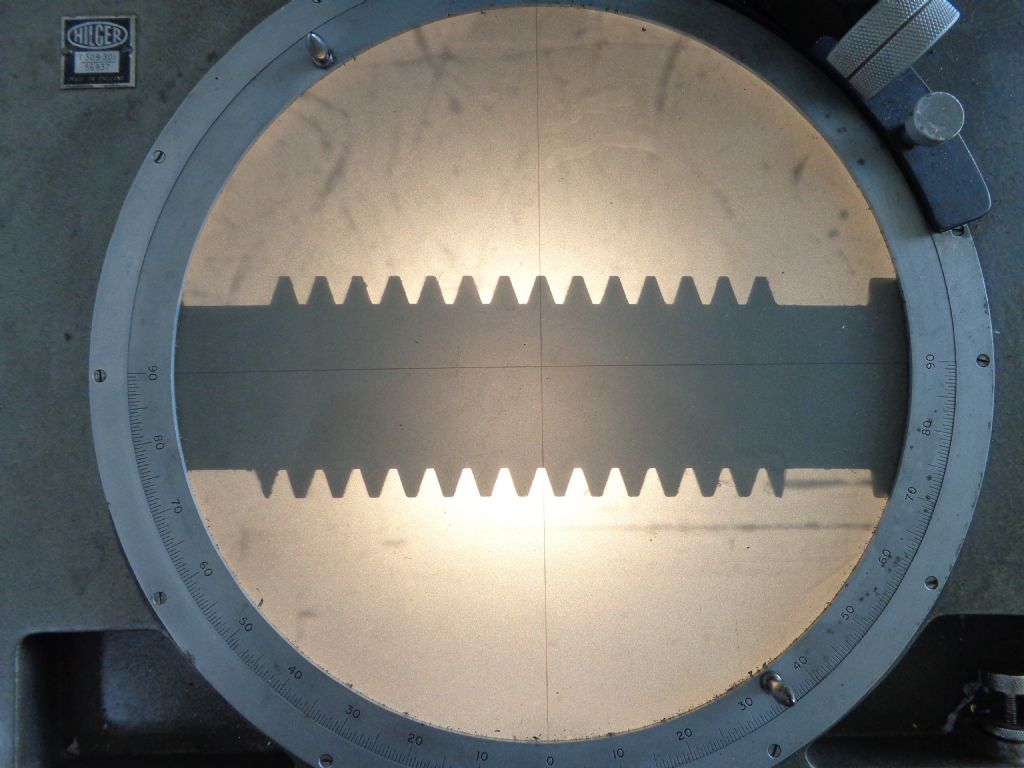

On the shadow graph at work just to see what it it looks like, not bad if I say so myself!;

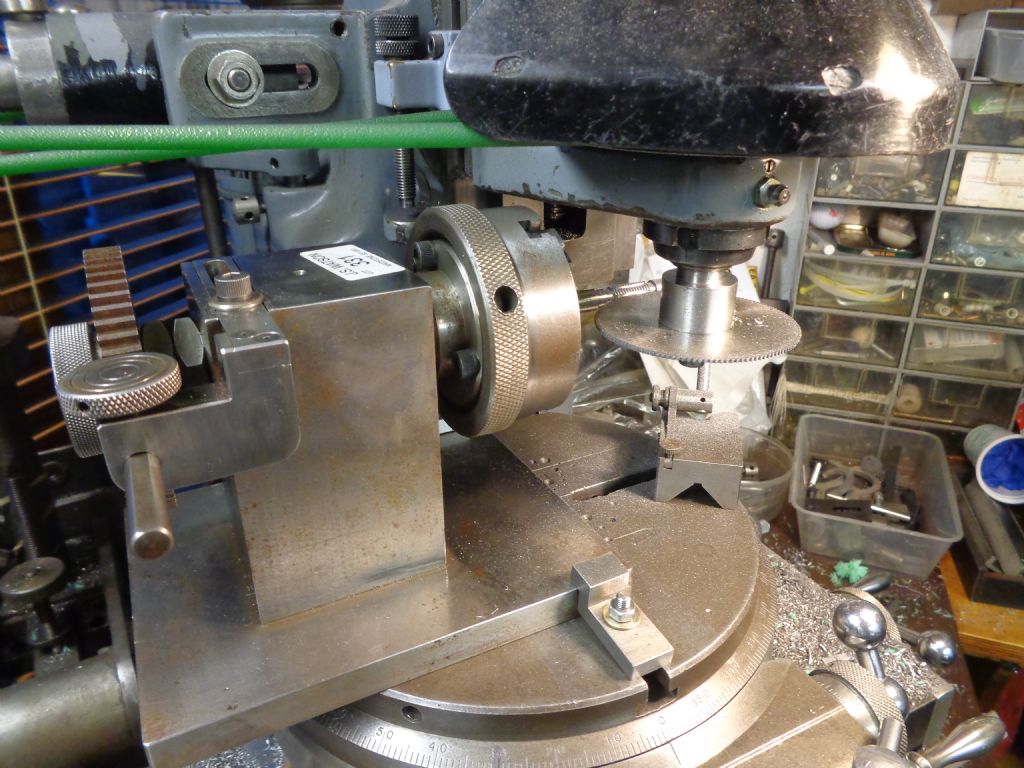

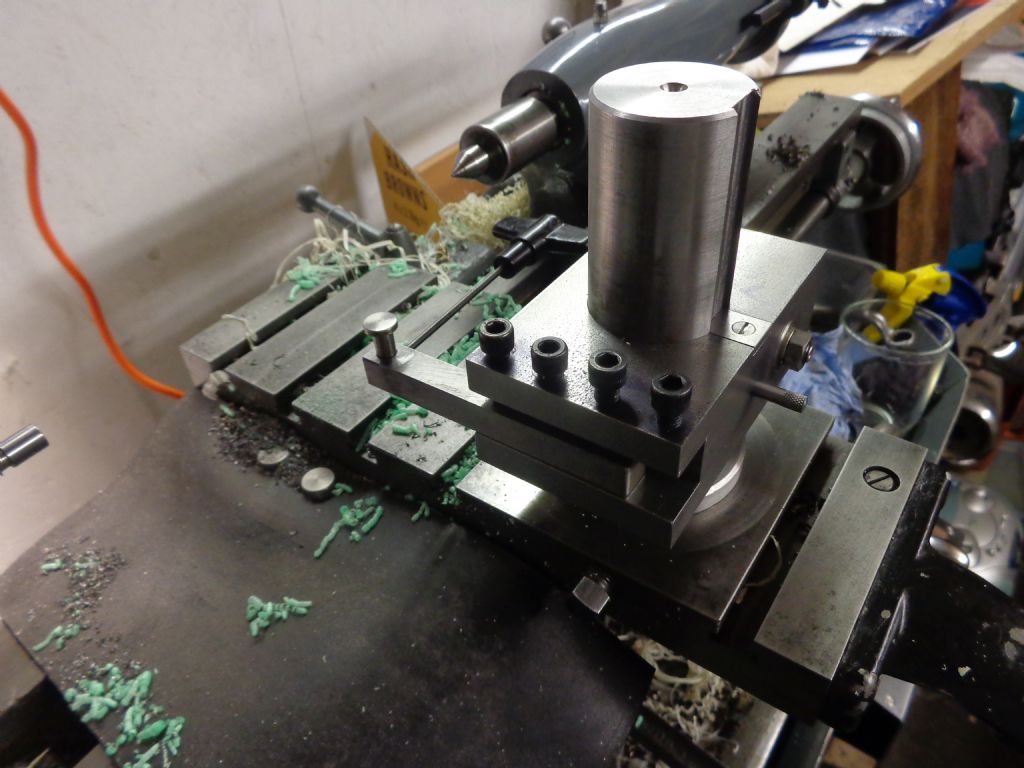

The lathe set up to hob the wheel (not the best I know);

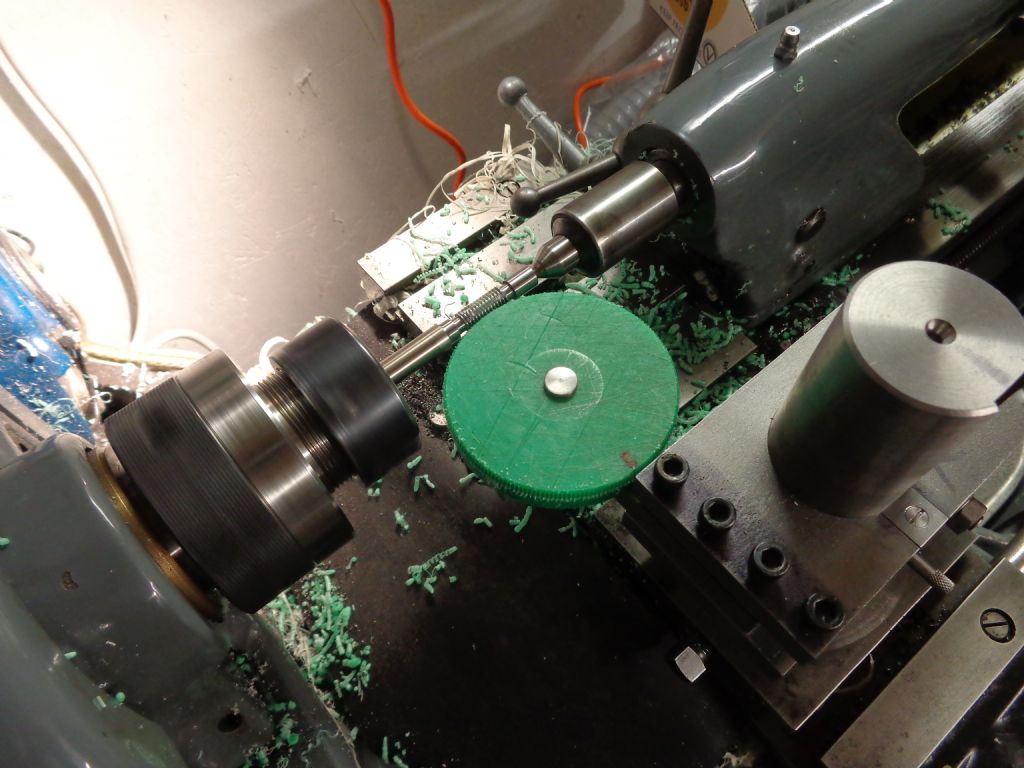

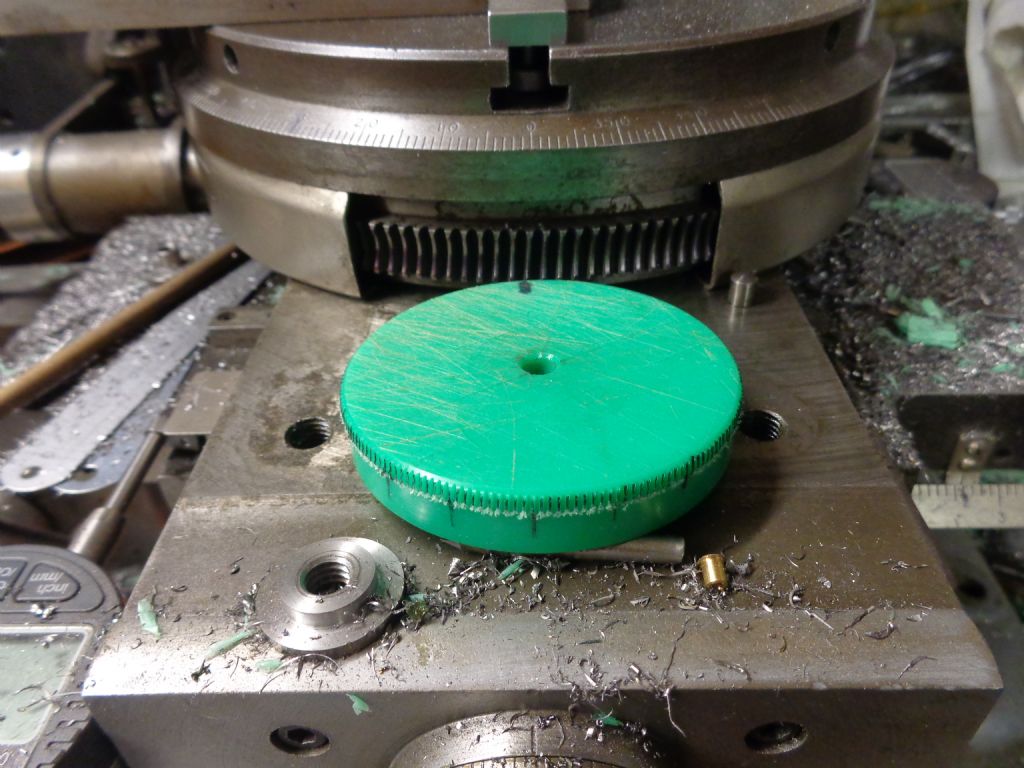

First test went well, an old chopping board was the material only issue was not making it single enveloping and not gashing caused 179 teeth;

Final test achived the magic 180t (gashed with a slitting saw) and a single enveloping wheel;

So all in all not bad, totally doable I reckon, I will now refine the hob in silver steel, harden then have a go in a piece of metal!

I think I will now take the time to do some drawings of the BCA, I might start a thread when I come to do my model for those who are interested.

Many thanks for all the input

William

Edited By William S on 01/07/2020 00:11:15

Edited By William S on 01/07/2020 00:12:13

Howard Lewis.