Very many thanks to everyone! Excellent responses.

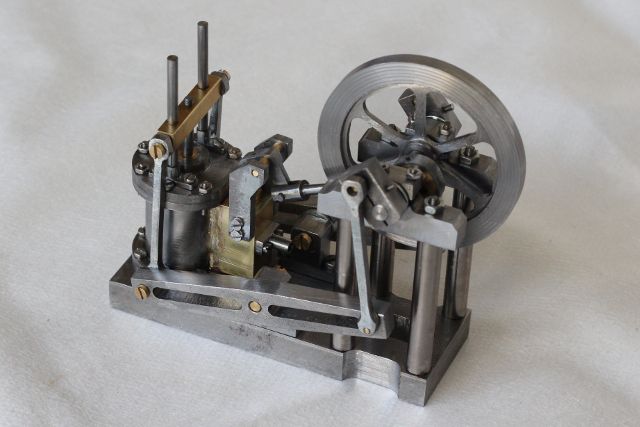

As a picture is worth a 1000 words here is a snap of the best side of the engine. It is 100mm long and needs more tidying up apart from the duff joint.

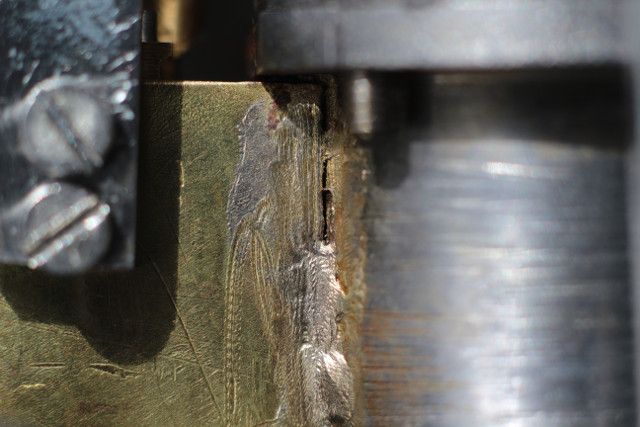

Next a close-up of the bad joint which is on the other side of the cylinder. The scale is given away by the out-of-focus M2 screwheads.

As it came from the hearth the fillet ended in an unsightly blob that I ground off with a Dremel. That's what skidded over the brass leaving the odd circular marks.

pgk spotted that my original post is ambiguous about the size of the gap; it's about 5mm long not 5mm wide. The overall joint seems to be mechanically sound but I'm suspicious about what lies beneath especially under the cylinder flange.

As it's unlikely that the engine will ever taste live steam I'm going to try soft soldering as per Neil and IDP. Michael's Locktite suggestion is very tempting but I don't have any 290 to hand and can't go shopping until Tuesday. Wensleydale will on my list.

Having read all your advice I'm much more confident about what to do next!

Special thanks to IanT who for answering the questions I should have asked for before melting expensive metal! My next go at silver-soldering will pay close attention to his words.

I tried to get EasyFlo but it seems to be Unobtainium because of the Cadmium content.

Julian's kind offer is very much appreciated. I'm trying to build skills but will be in touch if all else fails.

I shall report progress later.

Now I have a really big problem. Foolishly expecting adulation I made the mistake of showing the engine to my family today. Someone should have warned me of the need for slick, convincing answers to: "what's it for?" "does it work?" "how long did that take?" and worst of all "how much did it cost?" It seems that not everyone appreciates model engineering…

Best regards,

Dave

Ian S C.

)

)