Thanks again Roger,

I started a reply earlier but had problems adding a photograph, then lost everything – so I will start again.

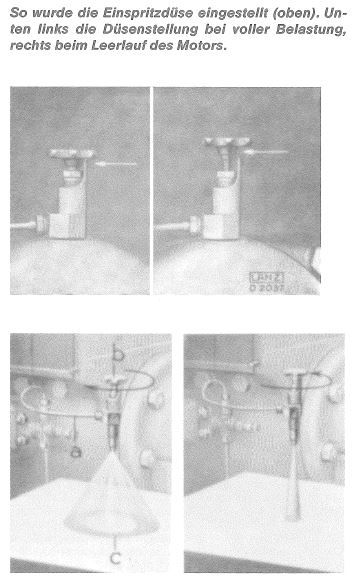

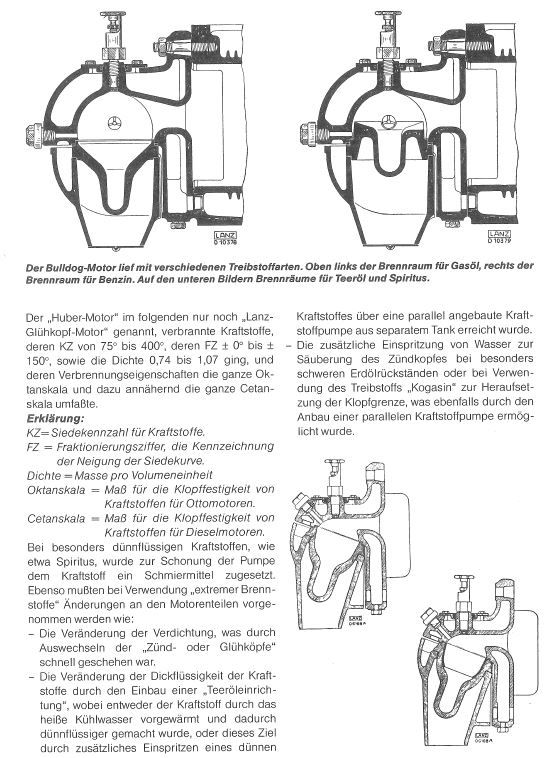

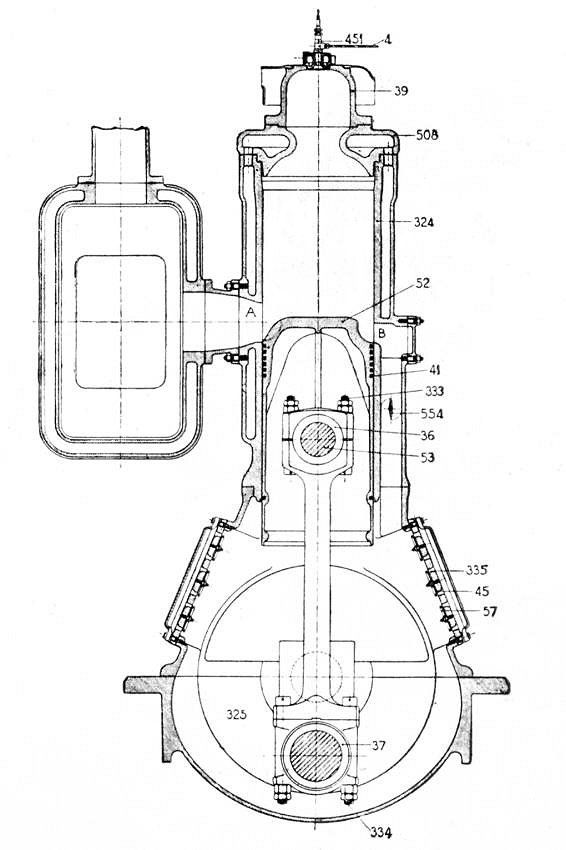

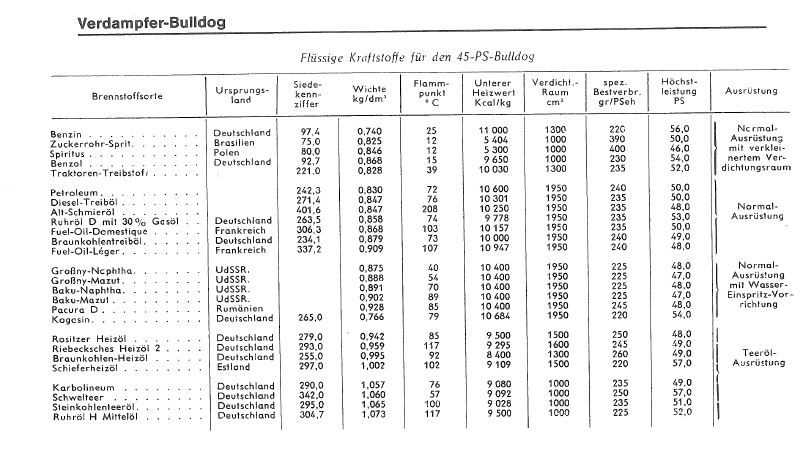

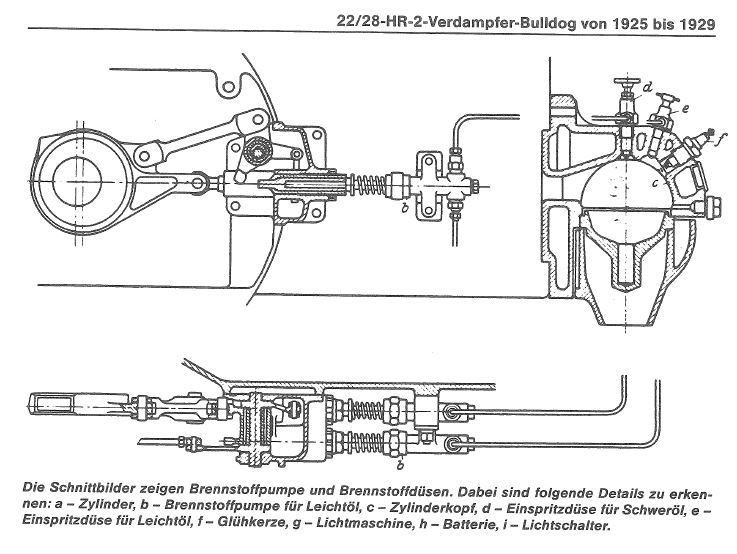

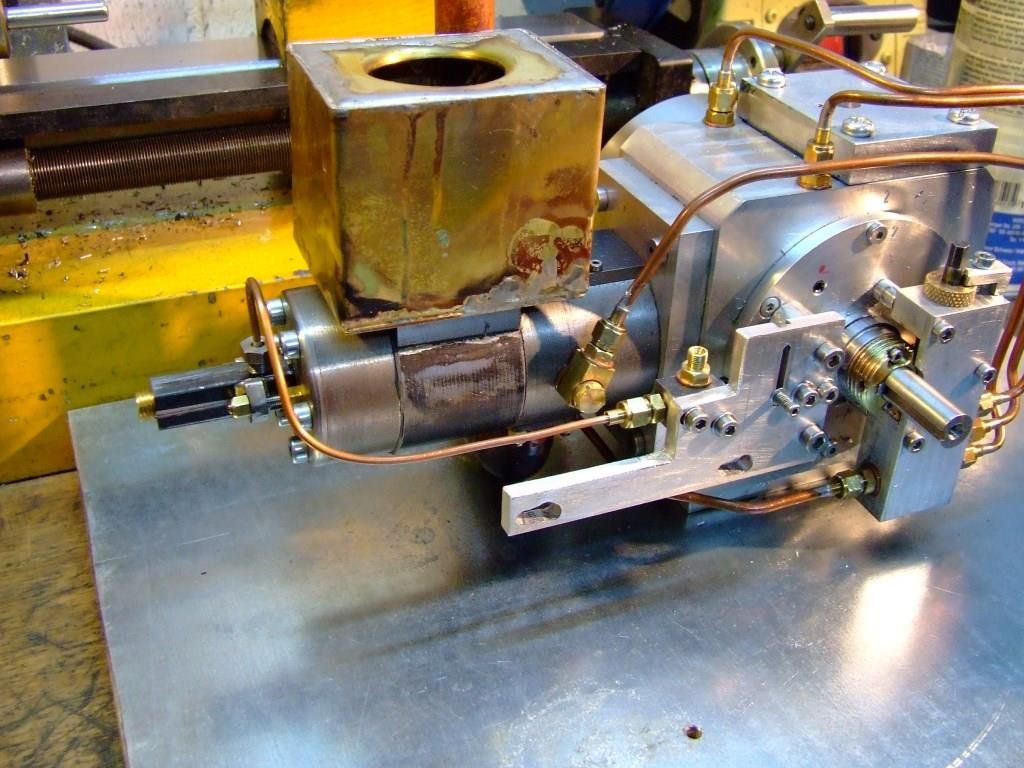

The information I have on the Lanz says essentially the same but in much less detail. I have also been trying to fill out the picture on use of petrol in these engines. They seem to have a version to run on this on a normal basis (although it is hard to imagine why anyone would want to do so.) What seems to have been more normal is using petrol to start up, then switch over to a heavier fuel once the key parts were hot enough – avoiding the need to use a blowlamp to heat the bulb. My understanding is that petrol was injected using the same injector system as the normal fuel and that they had a spark plug giving a continuous stream of sparks (like one gets from a trembler coil) so that ignition occurred when enough air had entered the head section to form a combustible mixture. I did talk to someone who has a lot of experience with these tractors and apparently this was hard on the engine and crankshafts have been bent or broken using this method of starting.

Any comment on this would be appreciated.

A couple of other points where I have been trying to get more "solid" information are compression ratio and injection timing: I have seen numbers of 6 or 7 : 1 for the compression ratio an 160 deg. before TDC for the start of the injection. Again any comment would be appreciated.

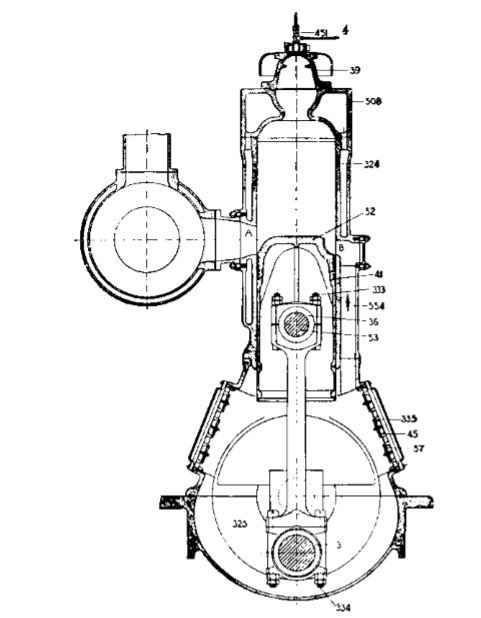

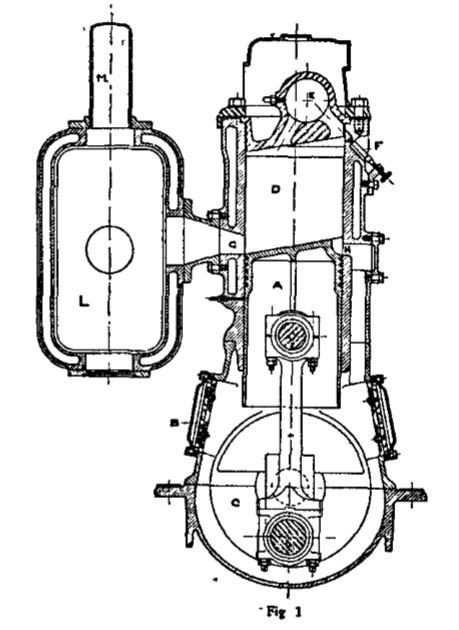

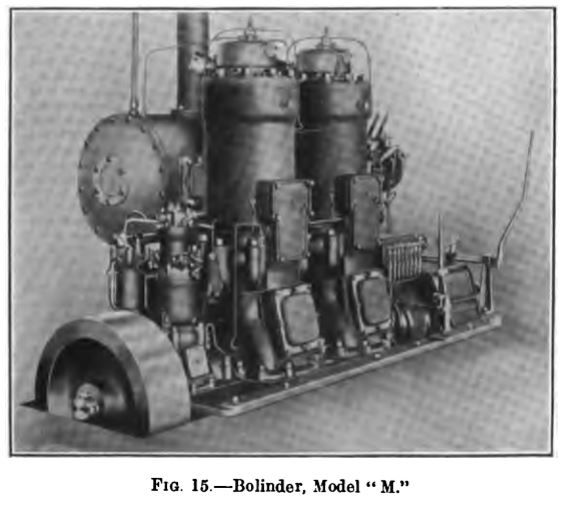

Turning to the Bolinder engine: I do have a manual for their B & W type engines and this shows essentially the same combustion chamber arrangement as your picture (but the design is slightly different.) This general arrangement seems to be the one they ended up with after a lot of development work and several different design iterations. Prior to this there was an E type (which is like the illustration in the Wikipedia article on hot bulb engines) and an M type that appeared ~ 1915. This had an air atomization system for the injected fuel. In the E type, water was used to suppress pre-ignition under load but there was a very clear incentive to avoid the need for this and the variable spray injector used in later designs seems to have achieved this objective.

One other thing they did to help maintain an adequate combustion chamber temperature during idling was to throttle the flow of scavenging air to the cylinder. This would have reduced the cooling effect of the incoming air. This approach was also used by Kahlenberg (and maybe others.)

What I have no been able to do is piece together the the chronology of these developments – and what else they might have done along the way. Again, information on compression ratios and injection timing are hard to come by. All the B & W manual mentions is injection starting about half way through the compression stroke. An estimate of compression ratio could be obtained by making a proper drawing from the sectional drawings given in the literature, then doing the calculations. But so far I have not done this.

I will try to figure out how to add pictures so I can share some of these but I will not try here and risk losing what I have posted so far.

Once again, any information you can provide to fill in the gaps in my understanding, would be appreciated.

Best wishes

John

Ther

John Lovegrove.