Hi Ian,

I did get an email but there was no message, not sure what happened there.

I was going to take the boys to Mc Lean’s Island to the steam society for a crank up with the vintage machinery club but the weather going to put a stop to that, shame, they have been asking when we go again to run their hot air engines for a crowd. Maybe the weather people will be wrong,

we can only hope.

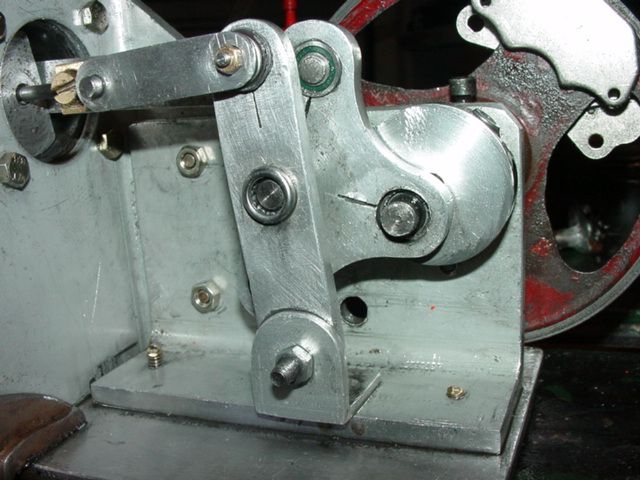

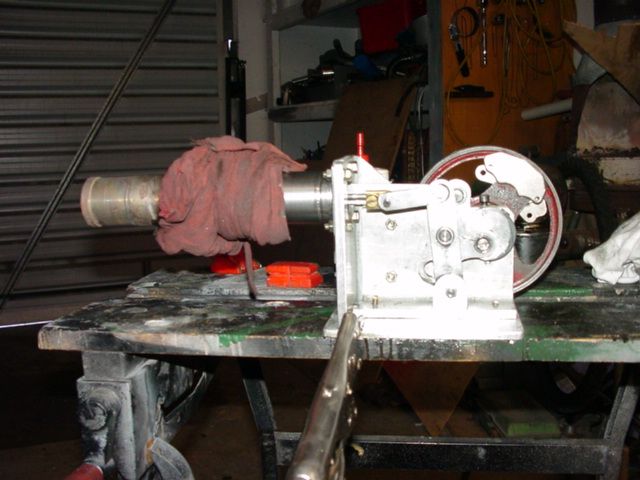

A friend has the engine above and he has been trying to get it running better, but since he started he has only made it worse; I fear he is going to damage it before he hands it on to me to fix. The main problem that could see was it leaks air at the flanges – no gaskets just gasket goo. There is no friction and it might leak back past the piston which is not a big deal so long it is at a minimum.

I did get it to run when he first brought it around but it took 5 minutes of gas flame before it started and was ant power. Also it has no cooling system and the heat transfered to the cold cylinder very quickly – maybe some wet undies might help here in the interim, what think ye? This engine should easily run with meths or a mamod tablet.

As for your computer, now I understand why I got no replies. Thought I was in the dog box maybe

.

Mark

SillyOldDuffer.

we can only hope.

we can only hope.  .

.