Posted by Martin Cargill on 19/10/2017 20:47:50:

I have a large selection of cutters but I don't know what speeds, feeds or depth of cut etc. that I can run them at. Can anyone provide any general guidance or point me towards any suitable literature.

Cutting speeds are the same as for any other machine tool. So, for HSS cutters, say 100fpm in low carbon steel, less for cast iron, more for brass. I always use flood coolant, where appropriate; there's a lot of heat being generated if you're running the cutter hard.

Depth of cut and feed can be much bigger than you think. It's taken me a while to learn that. I rarely use less than 4 thou per tooth and often quite a bit more. It all depends on how well the work is clamped!

The universal bit is straightforward, but you do need a universal dividing head to make best use of it.

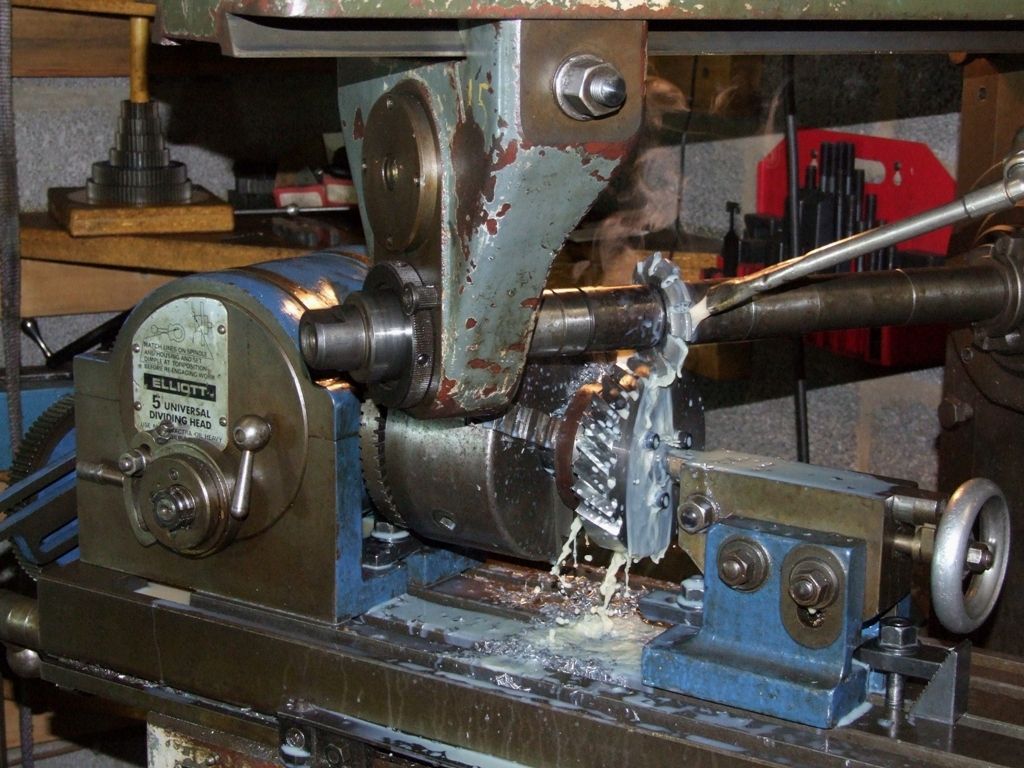

A few pictures might help. Milling hot rolled steel, width of cut 1", depth of cut 3/8" and 6 thou per tooth:

Cutting a 5DP gear in cast iron in one pass:

Hobbing a worm wheel:

Cutting a 6DP helical gear in one pass:

To summarise, it's a big, heavy mill, don't pussy foot about but give it some welly!

Andrew

Martin Cargill.