Welcome to the forum Martin

I guess you want a pressure gauge rather than a manometer. A manometer is a particular form of pressure gauge, and the type isn't really suitable for a steam engine. (The range of pressure they can measure is small, they're physically big, and don't like vibration.)

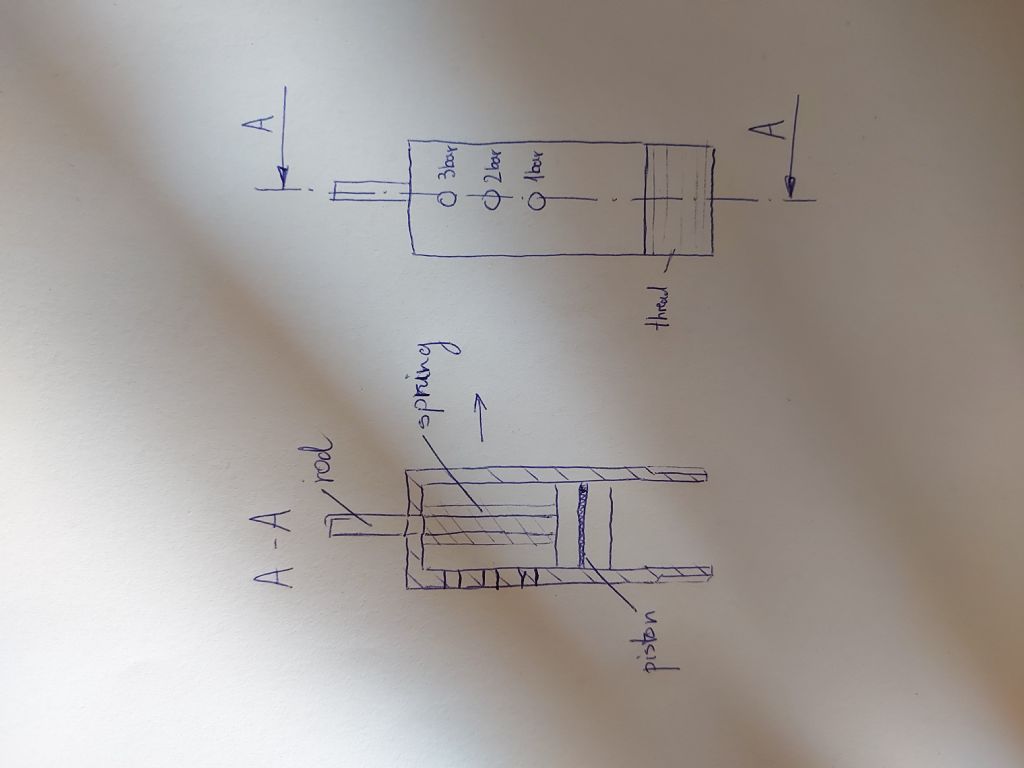

Your piston and spring would work. As would weights holding a V shaped piston down like a safety-valve. The problem with both is stopping the piston from leaking.

Mr Bourdon came up with a good answer in 1849 and this type of gauge is very common today. They're cheap, reliable and cover most ranges needed. Bourdon bent a flattened tube into a curve, which is also a spring. No leaks because the tube is sealed at the far end. When the springy tube is pressured, it straightens out in proportion to the pressure. The resulting small movement is used to drive a needle through an amplifying step-up lever and gears.

Rarely home-made these days because commercial gauges are so cheap and come calibrated and ready to go.

Though I've never seen a published design people occasionally make their own: I gather the tube is the main problem.

Usually Brass, it has to be springy enough to provide the wanted pressure range – not too stiff, or too light. Springiness depends on the type of Brass, how hard it is, the diameter of the tube, and the thickness of the walls. The radius of the tube matters too, and it can be coiled. The tube is flattened so that it opens out in one direction: round tubes move sideways as well as out.

Gauge manufacturers have all the information needed, but I don't think it's been made public. Therefore, a home-builder has to experiment. Great fun, but far quicker to buy one rather than build it.

There are other possibilities: if electronics are allowed, a strain-gauge could substitute for the needle, gear and lever assembly, and the range covered is decided by an amplifier. Electronic pressure gauges are available but ones that work at high temperature and pressure are expensive. Worth it for logging data or informing an engine management unit, but a pricey fuss if all that's wanted is a visual indication of boiler pressure.

Please report back. Be really good is someone built a Bourdon Gauge and explained how they did it.

Dave

Nigel Graham 2.