.

On with the flywheel.

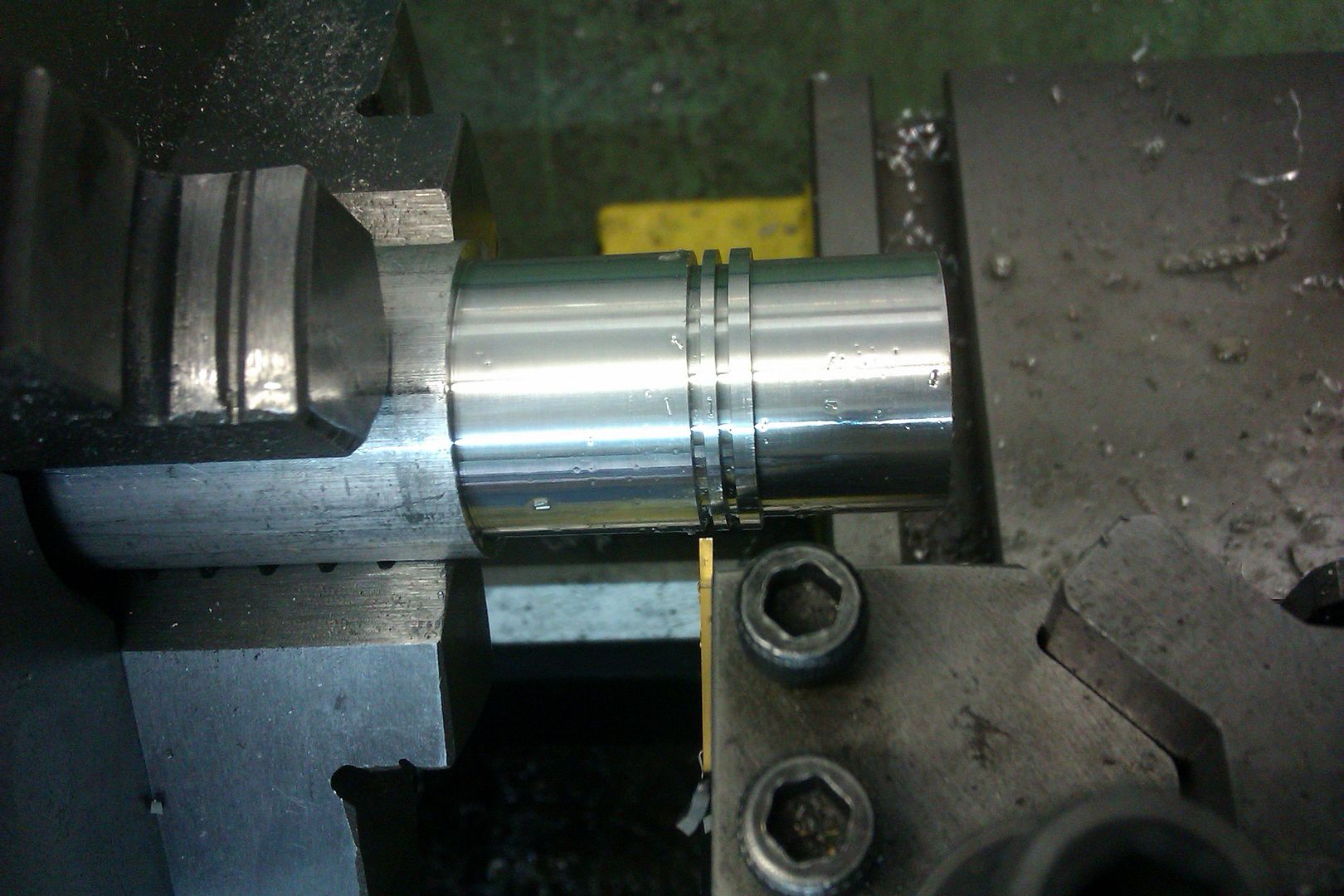

Billet was turned to make the centre hub to 4" dia.

After a cuppa and a few ciggs I plucked up the courage to butcher the 4 1/2" outside 3 1/2" inside bronze stock. I glue tacked some sacrificial washers to one side so that I did not run the boring bar into the chuck flange jaws.

I need not have fretted. It machined really nicely.

And tested the centre boss.

But don't it make you want to cry. All that bronze swarf.

– But perhaps it will make good pan scrubs for the kitchen.

– But perhaps it will make good pan scrubs for the kitchen.

I think it was the American machinist Kieth Fenner that said in one of his videos. "There is something about bronze to men. Bronze to men is the same as diamonds are to women." – Must admit it is nice stuff.

I did a PCD on the mill DRO of 12 holes that fixed the 2 parts together.

I need to go to my mates workshop so that I can broach a recess into the hub to enable a keyway to the crankshaft. Once this is done I will make a keyed mandrill to place into the lathe to turn the outer side of the flywheel. ………….. Yes Jason, your recommended tips have arrived.!

Nick

Roderick Jenkins.

Roderick Jenkins.