.

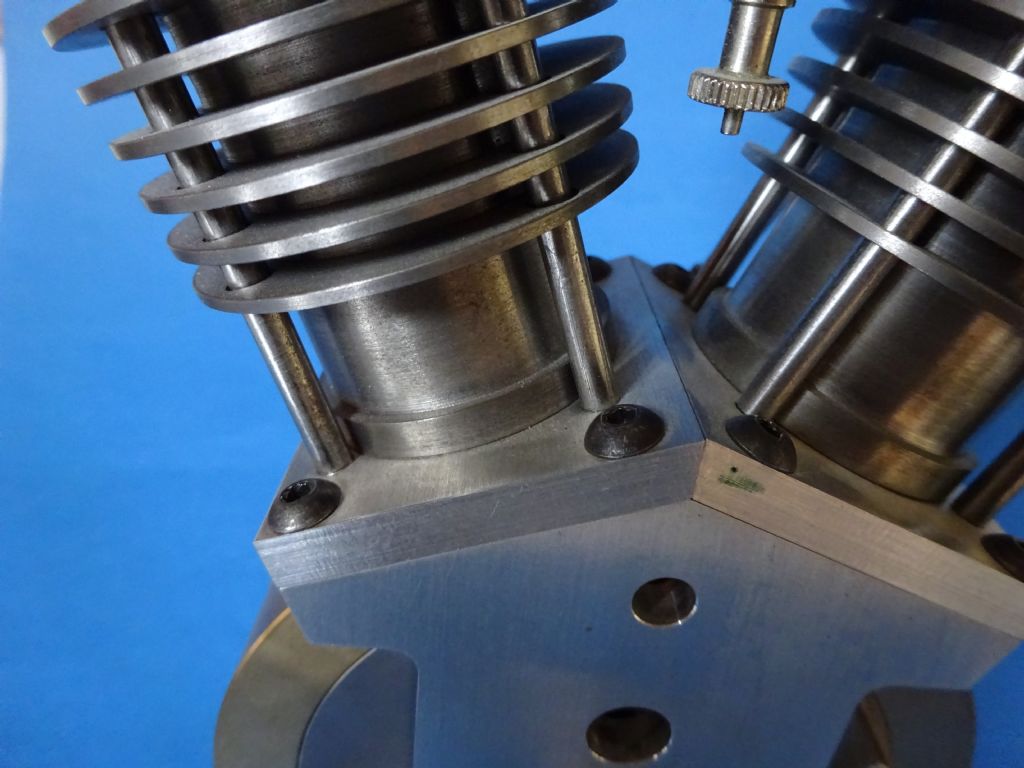

Thought I better do something useful with that metal. So had a stab at one of the cylinders.

The drawing calls for the cylinder to be made in one piece from cast iron. Many others though have opted to make them from aluminium and then sleeve with a cast iron liner. – I went for an all cast iron one as per the drawing.

Macc models did not have the close size for the cylinder dia. So I went a size larger and will part off the excess length I bought to make the cylinder head. (which is a larger dia) This meant I had to spend a bit more time carving down to the cylinder dia.

Then cut in the cooling fins.

Then ready to part off. – I think CI is really nice to machine if it's good quality stuff. Pity it makes such a damned mess though.

Fliiped it round into the collet chuck and a boring session we did go.! At this stage I also added the 5 degree taper to some of the fins. – The bore is quite a nice finish with it being nice CI. But left 1/2 though for a tad of honing.

Hey presto.

There is a wide groove to be made yet below the bottom fin that makes a step in the lower section to form a flange. I will do this later when I have both cylinders done and made a mandrel to hold them.

Now I have to make another one that 'looks'  exactly the same.!

exactly the same.!

Nick

Edited By Nick_G on 08/03/2016 23:36:38

Roderick Jenkins.

Roderick Jenkins.