Thanks everyone for your replies.

I did write to Teco Znojmo, the manufacturer of SU300. I haven't got a reply from them so far, I will call them at some point.

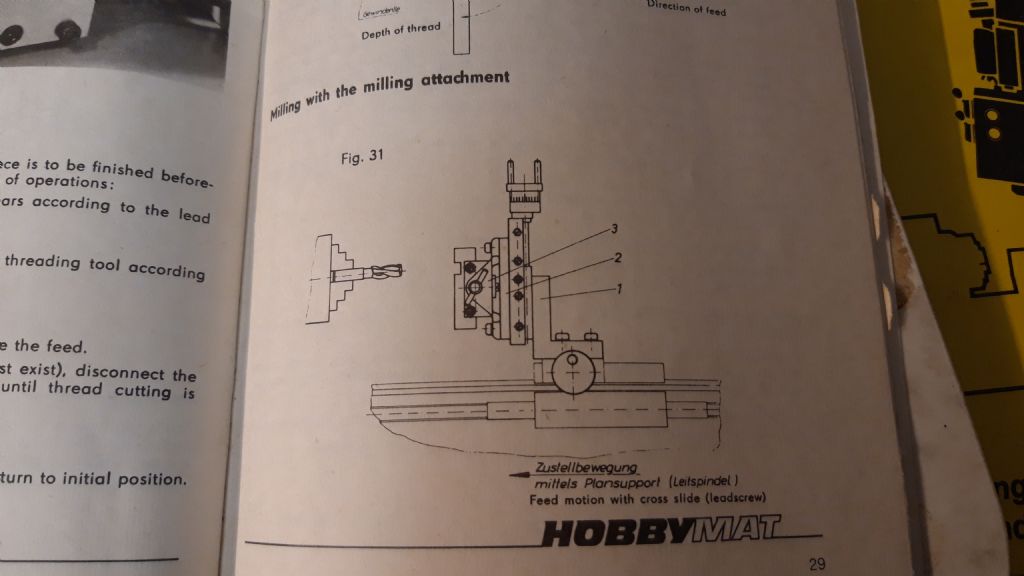

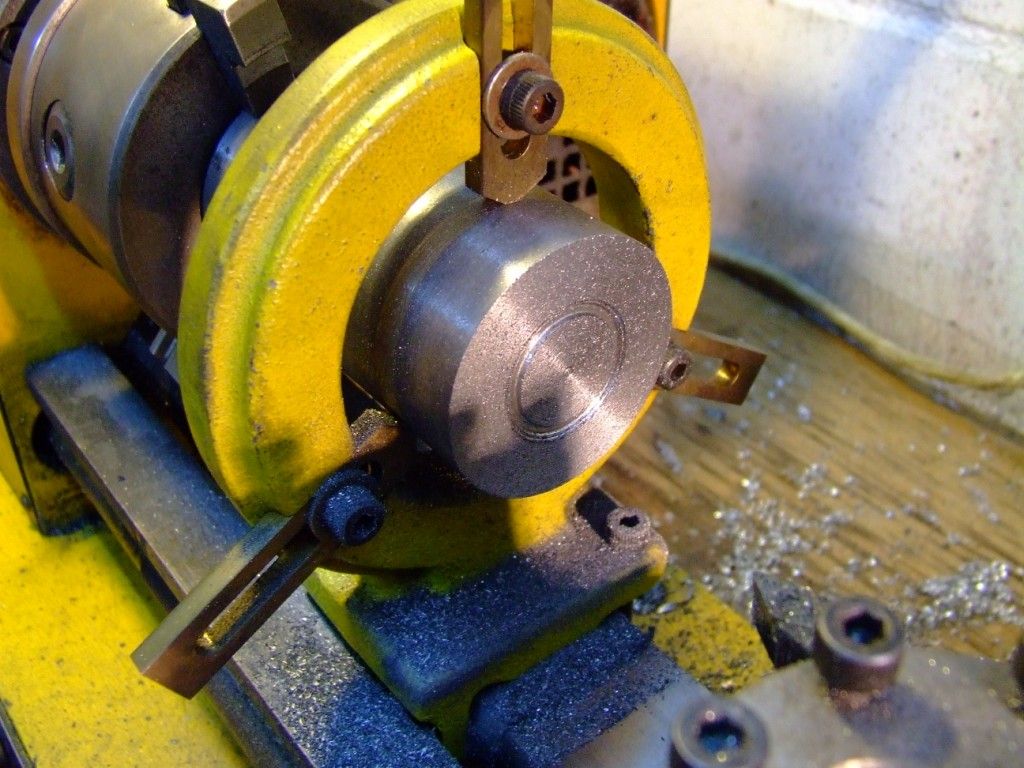

I understand know, thanks to the picture in the manual, how the angle plate and vise are installed to allow movement along 3 axes, and thus can be used for milling.

I am, and will be, checking for the BFE65 milling head, or the complete BF400 mill on various auction and classified websites. I've read on several forums, that when mounted to the lathe, the milling head doesn't give too good results due to severe lack of rigidity (this was also said about combination lathe/mills, in general). Perhaps that would be still quite useful for tasks where high precision is of less importance.

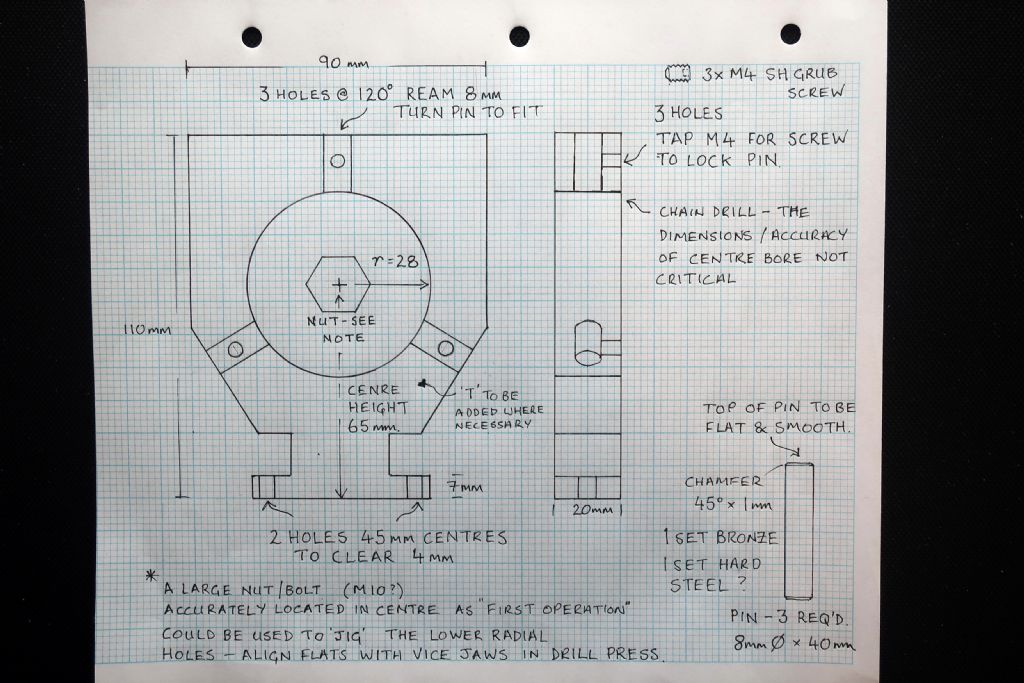

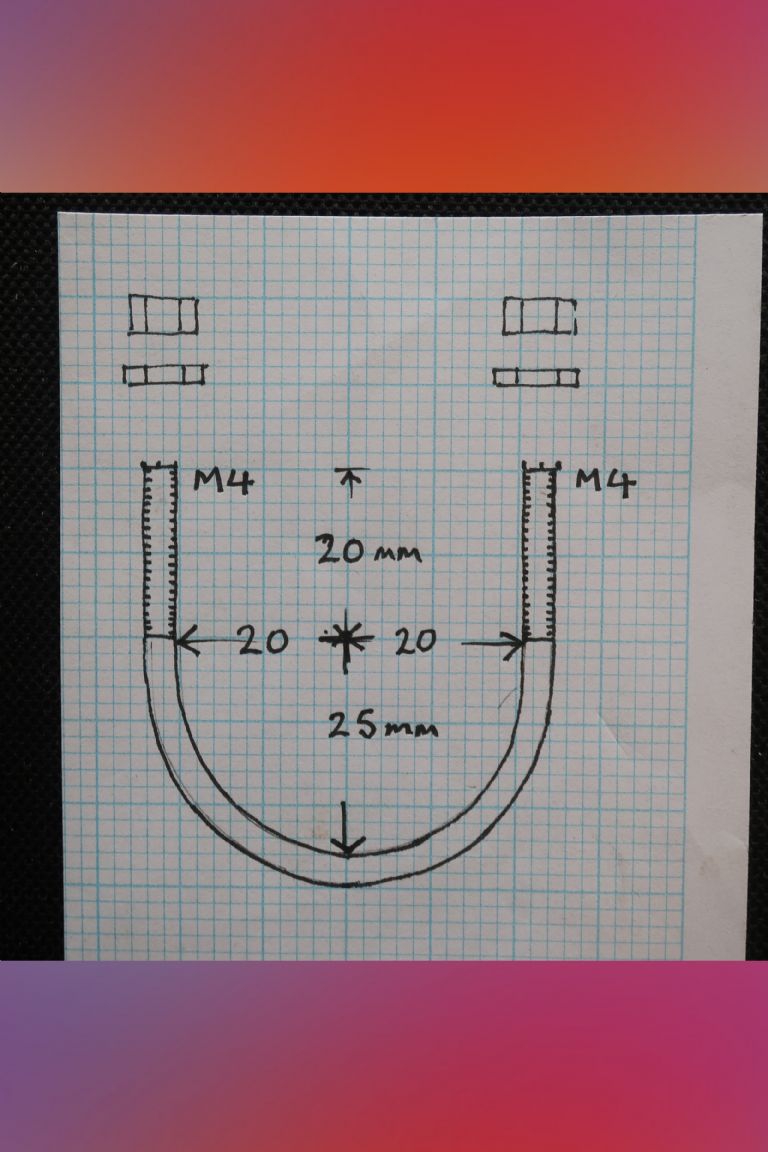

I'm now starting to contemplate the possibility of machining a fixed steady using only the lathe. I am not sure of the maximum capacity that the Hobbymat vise can hold. It looks rather small on the picture, I might have to use an alternative fixing arrangement for securing the steady on the top slide? I'm also wondering how a hole in the middle of the workpiece should be bored? Would you recommend to use aluminum or steel for the steady?

I'd like to follow Harold Hall's book in the order it presents the content, however it seems like I'm gonna have to jump around to read about the operations I would need to do to machine the steady. Looks like there's a fair amount of milling involved, I've ordered a Milling Operations in the Lathe (Workshop Practice Series, Band 5) book by Tubal Cain, hopefully that would provide enough information.

If someone has a rough outline of the process, it would be helpful to hear it before I start trying it out myself.

Most of the forum and blog articles on the topic include the use of a mill, rather than using only the lathe. But surely I'm not the only one contemplating doing it on the lathe alone. Harold Hall's books also mention that some years (decades) ago many home workshop owners had access to only one machine – a lathe. Not even a drill press in some cases. And they managed to produce quite impressive results with the lathe alone. I guess it could be fun to try to work under these limits, although if I had the space, I would probably get a mill as well

Thanks again.

P.S. Hopefully I will be able to pick up the lathe this weekend or early next week. It's a bit of a difficulty, since it's in Ashford area, I'm in Luxembourg, but I come from Russia and I don't have a visa from UK. Initially I had enlisted a local neighbour to come with me to Calais, then he would cross the channel alone by Eurotunnel, and drive to pick up the lathe and come back. However he couldn't make it, so now I'm hoping to find someone from Ashford or Kent who would pick it up and bring it to Calais.

–Gene

Michael West.