Hi Peter,

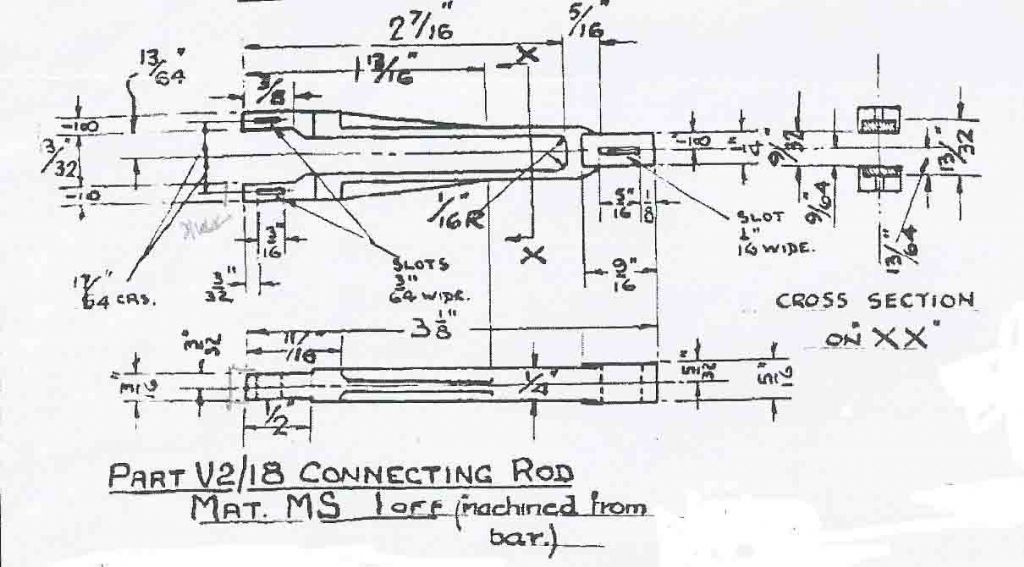

For Norden I had to make similar slots 1/16" wide. That extra 1/64" seems a lot!

The slots will be hidden so they don't need to be perfect, although the end the key bears against needs to be correctly placed.

After I finished my engine someone suggested drilling axially down from the curved surface for the bearing. This can remove a significant proportion of the metal the slot has to cross, and at the centre, the hardest part to reach.

Now chain drill the slot with a 3/64" drill as accurately as you can. It may be worth drilling from each side in turn rather than trying to do so in one go.

Now cross your fingers and using a 1mm end mill as fast as it will go and taking cuts of no more than 0.4mm or less gently remove the metal between the chain drilled holes.

If you are lucky the tip of a flat but pointed (does that make sense?) diamond file will enter the slot and let you tidy it up.

An alternative rout would be to make a chisel from gauge plate or silver steel with a short tip 3/64" thick and 3/32" broad. Bevel it so the cutting edge is at one, narrow end. A second with the cutting edge on a long side could be useful.

You can either use this by hand to chip away between the drill holes or, if made on the end of a silver steel rod, you may be able to use in the mill with a gentle up down planing action.

Final thought, as 1mm end mills snap very easily, an alternative would be to file a d-bit shape on the end of 3/64" silver steel, just for about 3mm. Make one at each end of the rod so you have a spare immediately to hand. This will be slower, but if carefully tempered will probably outlast and end mill (which will probably be far too long in the fluted section, and therefore too fragile).

Neil

P.S. I'm sure someone else will suggest spark erosion, and that's probably the best solution of all, but requires making a whole new machine.

Peter Wood 5.