Welcome!

You have found the right place for help.

Don't know the R and A, but there will be others on here who have and / or know it and can provide fdirst hand advice. Would guess that the threads used on the machine will be Whit form, so BSW (coarse ) and as the name implies BSF.

Where are you located?

If you can find a model engineering club within a reasonable distance, join it.

Some face to face tuition will be most useful, in all respects.

My two penn'orth

To learn the names of the parts of the lathe, and how to set it up and use it, buy some books, (Always useful for reference as well as being learning aids ).

If you wrongly name a part, either your question will not be answered, or will be misunderstood, and you will get an answer to a question that you have not asked, or one that you do not understand.

Firstly, you will find a set of Zeus Charts an invaluable reference

Possible books:

Ian Bradley "The Amateurs Workshop" Covers benchwork as well as lathework and setting up a lathe. Possibly a bit better in some respects than the "bible"

L H Sparey "The Amateurs Lathe".

Harold Hall and Neil Wyatt have both written books on lathework.,

For more detailed questions, books in the "Workshop Practice Series" will be useful as you progress.

Tubal Cain's "Model Engineers Handbook" is also an invaluable reference on many subjects.

Changewheels; Those for the RandA may not be the same as ones for other lathes in dimensional aspects (Bore, Width, Diametric Pitch, Pressure Angle to blind you with science ) so only use ones to the correct spec.

You may find them difficult to come by.

Backlash

ALL machines have to have clearance, otherwise parts could not move relative to each other.

It is not unusual to find 0.020" backlash in Cros S;ides and Top Slides. The essential thing is to be able to deal with it.

So, if you overshot when putting on a cut, withdraw by almost one turn, and then wind back in to where you wanted to be.

In this way, picking figures out of the air, a Slide with 0.025" backlash needs to be retracted by more than 0.030", by at least 0.050" so that when the handle is wound in again, the backlash has been taken out.

You also need to ensure that the gib strips are correctly adjusted. They keep the slides in close alignment, ,but not so tightly that movement is hard.

Some more money to spend will be on measuring equipment, if you do not already have any. A Digital Calliper (About the cheapest will be from somewhere like LIDL or ALDI, for about £10. Better will be a Moore and Wright from someone like Machine DRO for about £24.

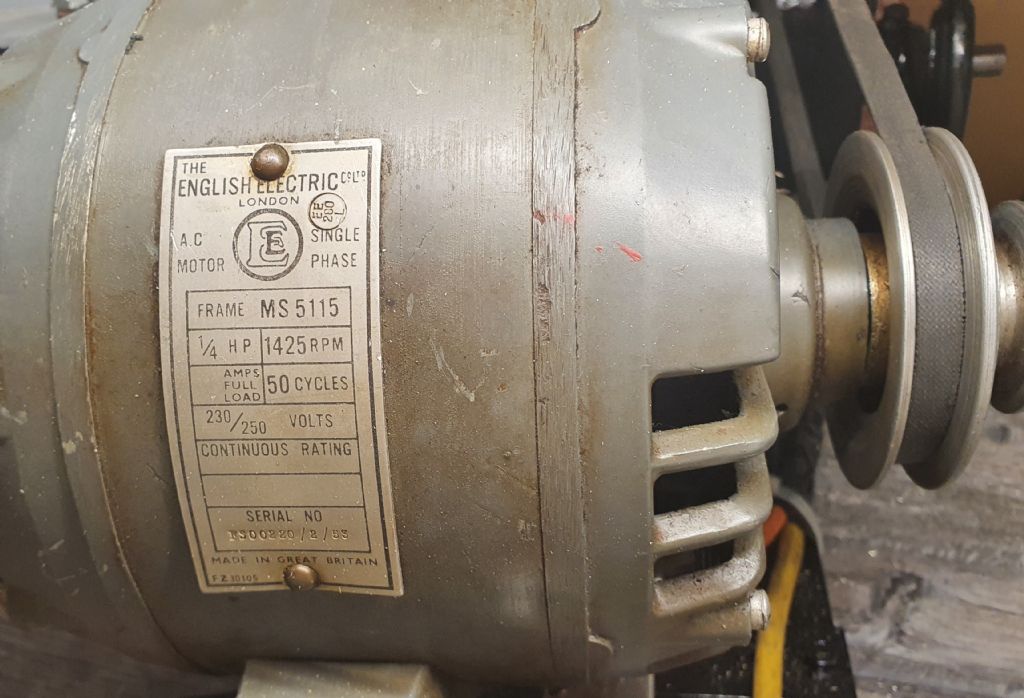

Your lathe is old, so will not benefit from, or be suitable for carbide tooling, so High Speed Steel should be your choice. To sharpen HSS tools and toolbits, you will need a bench grinder. The books above will tell you about the angles at which to grind.

Tools should be mounted with the cutting edge on centre height, if they are to cut properly.

When you get a 4 jaw chuck, (You may very well have to make a backplate for it. Which will initiate you into the joys of drilling and tapping as well as turning and facing )

Centering work in a 4 jaw will launch you into more measuring kit, at leasat one Dial test Indicator and a Magnetic Base. This will allow you to centre work in the 4 jaw more accurately than a 3 jaw.

It is MOST unlikely that you will find a 3 jaw chuck that holds work absolutely concentric

So, a lot for you to mull over! already.

HTH

Howard

Howard Lewis.

)

) ) I am project engineer and I have spend a lot of time with machine operators to squeeze every bit of functionality out of the machine.

) I am project engineer and I have spend a lot of time with machine operators to squeeze every bit of functionality out of the machine.