Posted by Brian Wood on 22/10/2021 17:51:56:

I would be very reluctant at this stage in your knowledge of this lathe and it's potential habits to strip it down just to establish what sort of bearings the spindle runs in. Not only will you disturb any preload setting, without knowing what it should be set back to afterwards, but you run the risk of introducing foreign bodies into the bearings in taking it apart and putting it together.

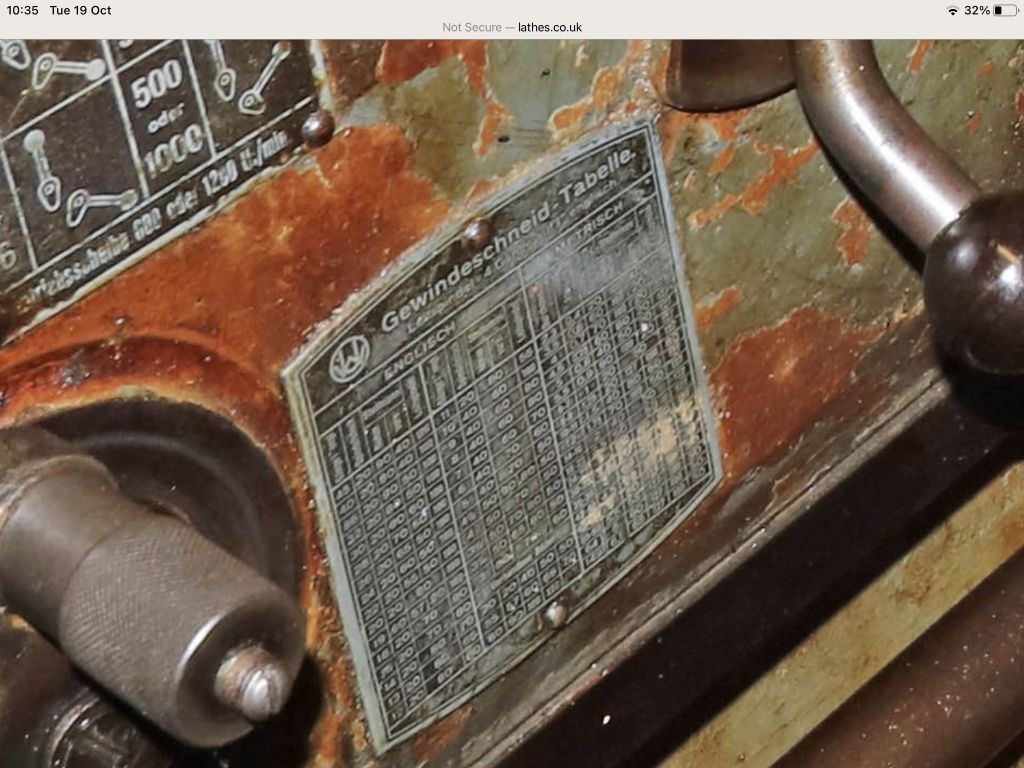

Does it really matter that much what the bearings are? Spindle speeds are given on the information plate and I would stick to those as a guide to see how the lathe performs before any such invasive surgery.

Thus far I don't think you have cut any metal on it yet.

Brian

Edited By Brian Wood on 22/10/2021 17:54:13

I am just trying to get info for the lathe still, i have not yet touched it but for a clean down. rebuilding this cant be any harder than an engine which i can do, but yes the settings to rebuild it i still need to find out which is what i am trying to do still, very little info found still on these lathes. you dont ask you dont know, so its all gathering info for now.

I plan to get the new motor fitted first on a new cabinet i will building soon, then see how it runs. oh yes first new oil added once drained. i cant find a drain so it will be pumped out with a sump pump i have from when i serviced boat engines. what gets me is the vary in folks idea on what oil to use for the head stock.

wayne ollerenshaw.