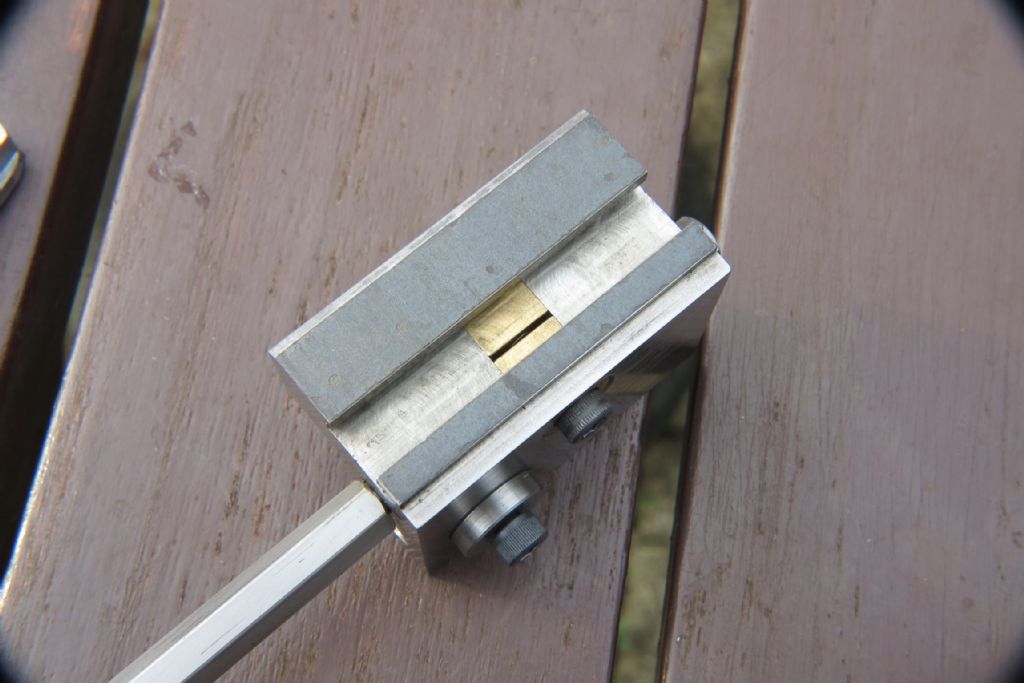

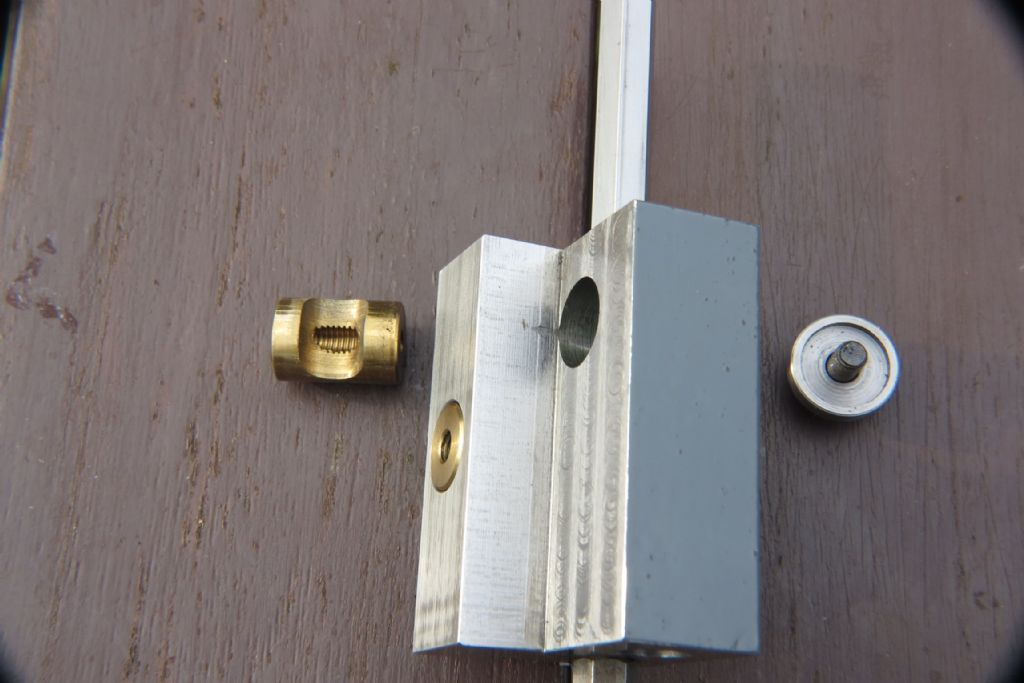

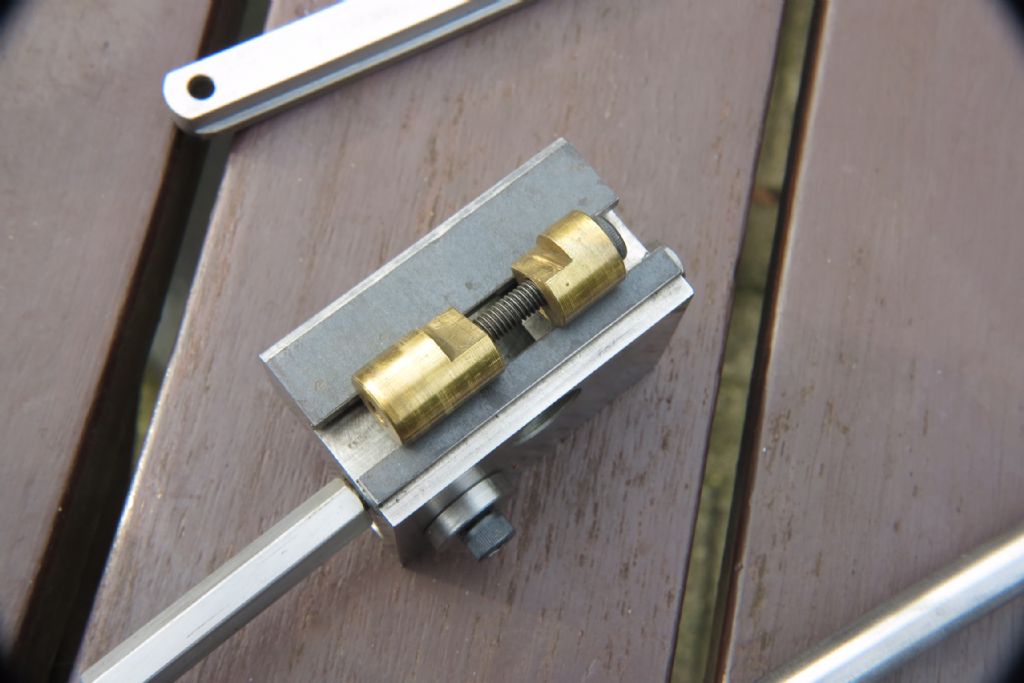

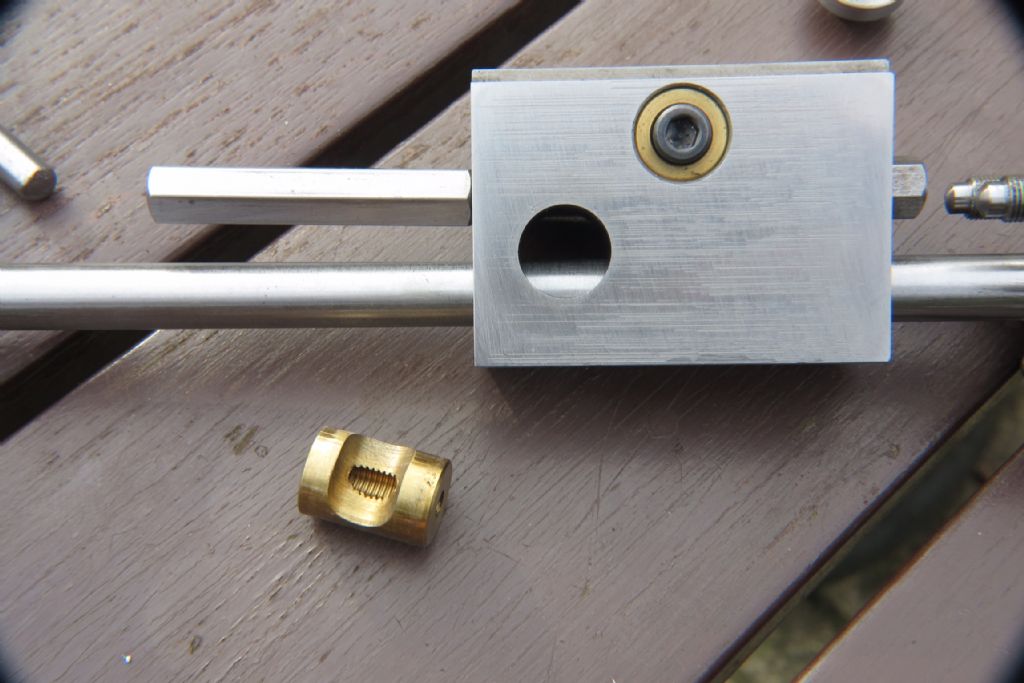

Actually Baz my issue with it was the screws were too long. I was turning pivots on clock arbors with the material in a Myford collet so the tool tip needed to be very near the spindle nose. The screws shown could only be wound in until they touched the mounting block. My solution as I was reluctant to cut down the nicely blacked screws was remove them all and intsall a cap head screw in one of the positions screwed right in. That gave me a dead stop with the top slide adjusting for exact length.

The Myford boys were just playing around with an idea and made a few up for the show.

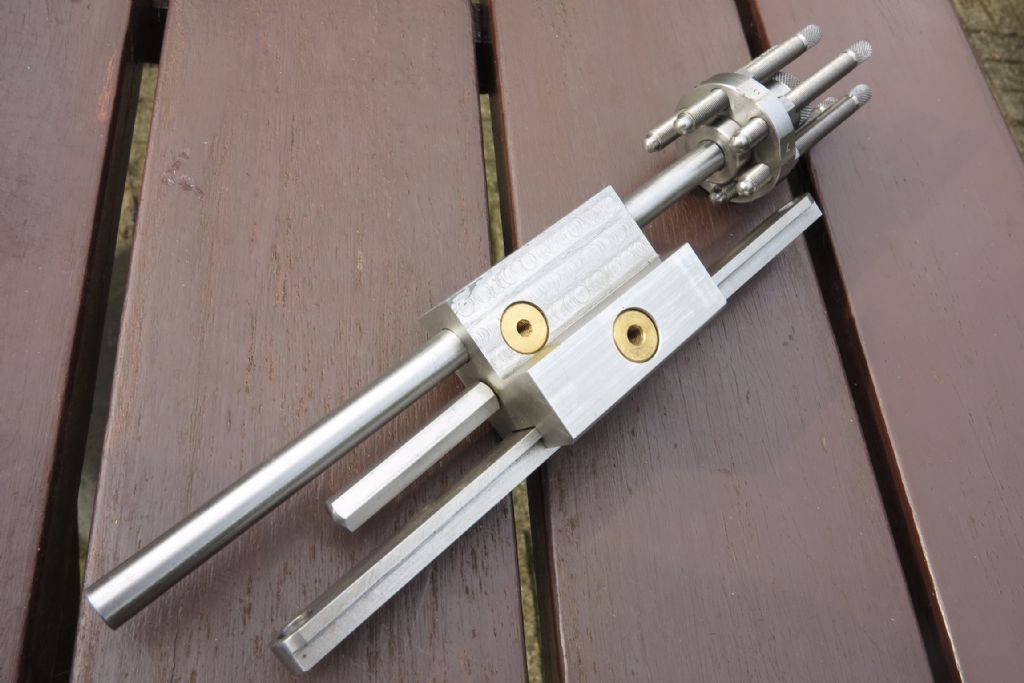

I have never really missed not having a saddle stop until I bought this one but I can see it is handy now and again.

I do have Graham Meeks Saddle handwheel which I find a great help.

I guess it makes it even less likely that I will modify my Hemmingway kit but you never know.

regards Martin

Martin Kyte.