Hi Folks,

Many thanks for your comments. I have had a bit of time off this build. Lost interest a bit, but recently got the urge back to continue.

I have got quite a bit done but had the odd issue. The first thing I did was to sort out the riser for the vice. I had drilled and bored out for the vice screw as one of the first jobs I started with. Needless to say, they were miles out. I ended up making an aluminium block that was a good tight fit in the slide way of the riser that I could use to pick up the edges with an edge finder.

Before doing that, I set the riser up in the vice and ran a DTI down the slide way. Once I had picked up the centre, I bored the handle end until I had taken out the error, it ended up ~14mm

The other end wasn’t as bad, I managed to set it up the same and a 10mm endmill sorted it out.

I had to adjust the vice screw to my new dimensions. As I want the vice to operate the ‘right’ way, I got set up and screwcut a 1/2” BSF Left Hand thread, finishing it off with a die.

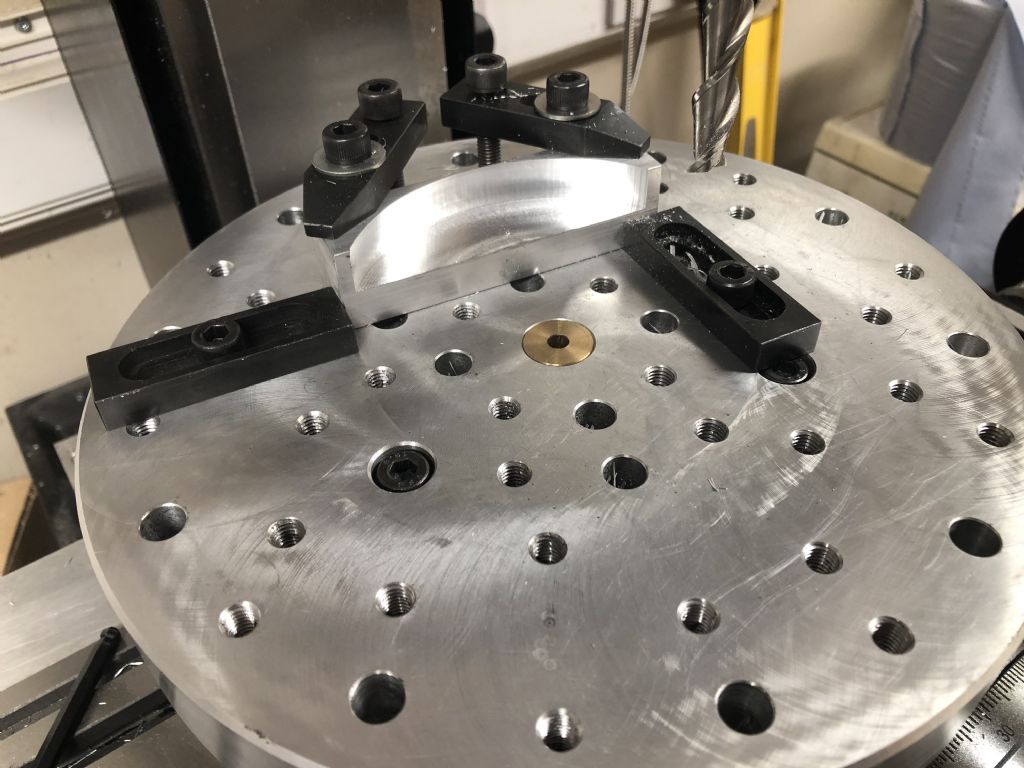

Next job was to set up and bore out the bottom brackets to 5/8”:

Then I got set up to make the drive shaft. This calls for a piece of 1/2” bar to be turned down to 11mm. I ummed and aaared as to how to set this up, but ended up with a small chunk in the 3 jaw and a live centre at the other. The first skim cut showed the tailstock being out of alignment. I had nearly .4mm difference over 5”. There followed a round of adjust, skim, mic, repeat until I got it down to .04mm

Done, in the mill and slot cut for key, key made and in, finished:

It ended up at 10.996mm one end and 10.992 the other. The hole in the gearbox is a touch under 11mm, as a piece of 11mm ground rod will not fit. (I bought it to save making this…..)

Cheers

Mark

Mark Elen 1.