Help with Northumbrian cylinder casting

Help with Northumbrian cylinder casting

- This topic has 4 replies, 3 voices, and was last updated 4 October 2014 at 15:43 by

Phil H 1.

Viewing 5 posts - 1 through 5 (of 5 total)

Viewing 5 posts - 1 through 5 (of 5 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Measuring increments on boring head

- DIY Pendulum Timer – GPS-Synced Beat Analyser

- Machinery Handbook

- Use horizontal mill as saw for metal?

- Steam pressure using thermistor

- Damp proofing concrete floors

- Hammant & Morgan “MINIPACK”

- Supply company catalogues

- Easing out the bore of a 3-jaw, s/c chuck

- Myford Super 7 restoration problem.

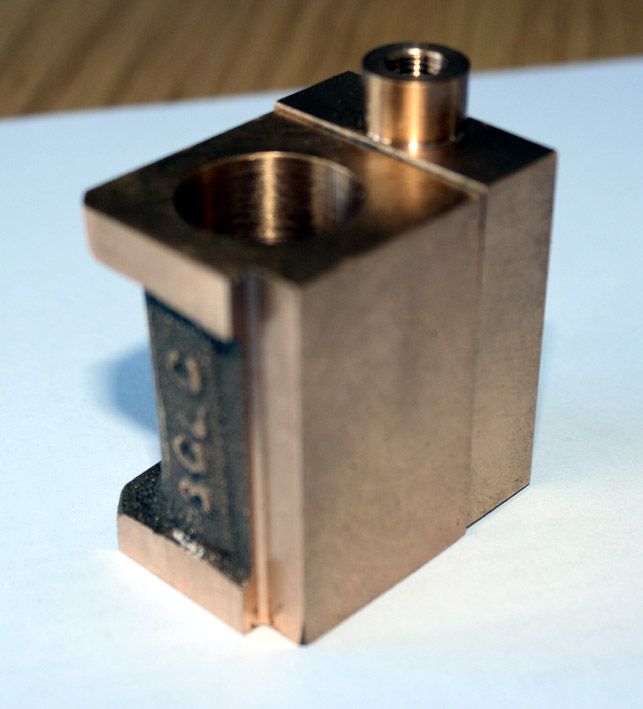

of the cylinder with a boss for the steam inlet. That's why the steam chest appears a little bit longer than the cylinder. However, you will notice that the width of the steam chest is a tiny bit wider than the cylinder. I did this on purpose so that the cladding sheet sits flush with the steam chest. I just need to round the cylinder cover bolting flanges using filing buttons. I hope these shots help. Phil H

of the cylinder with a boss for the steam inlet. That's why the steam chest appears a little bit longer than the cylinder. However, you will notice that the width of the steam chest is a tiny bit wider than the cylinder. I did this on purpose so that the cladding sheet sits flush with the steam chest. I just need to round the cylinder cover bolting flanges using filing buttons. I hope these shots help. Phil H