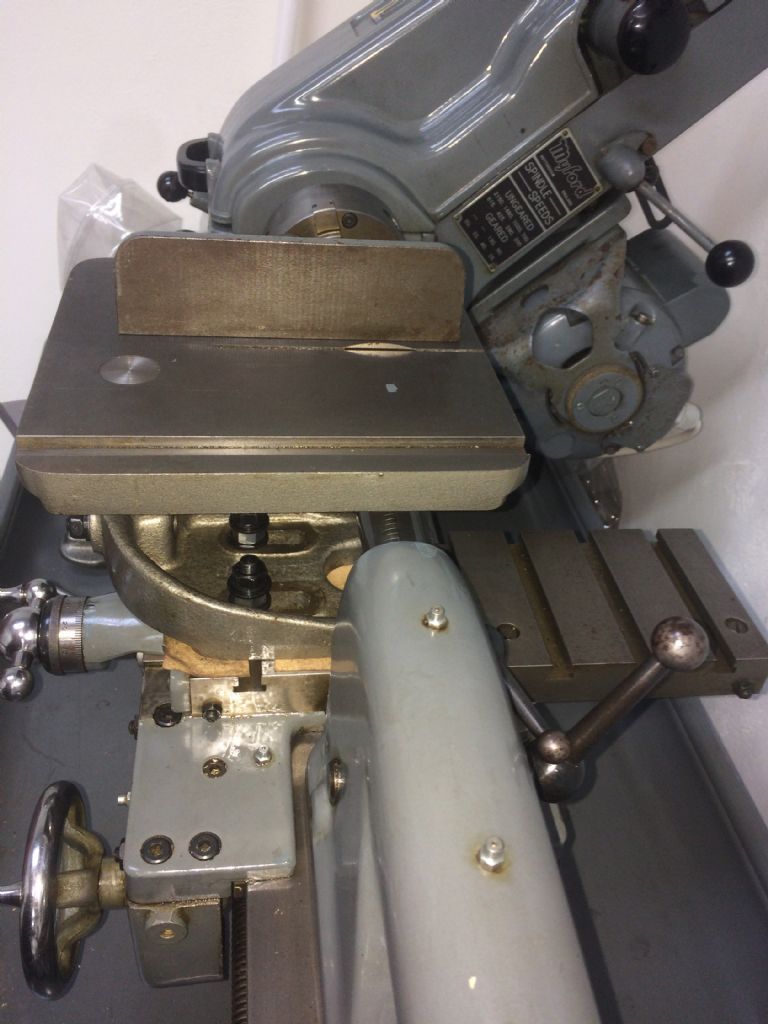

WIth a job to do soon, I spent some time yesterday trying set-ups for a Myford saw table. Wondering if anyone has specific experience with one of these they can share.

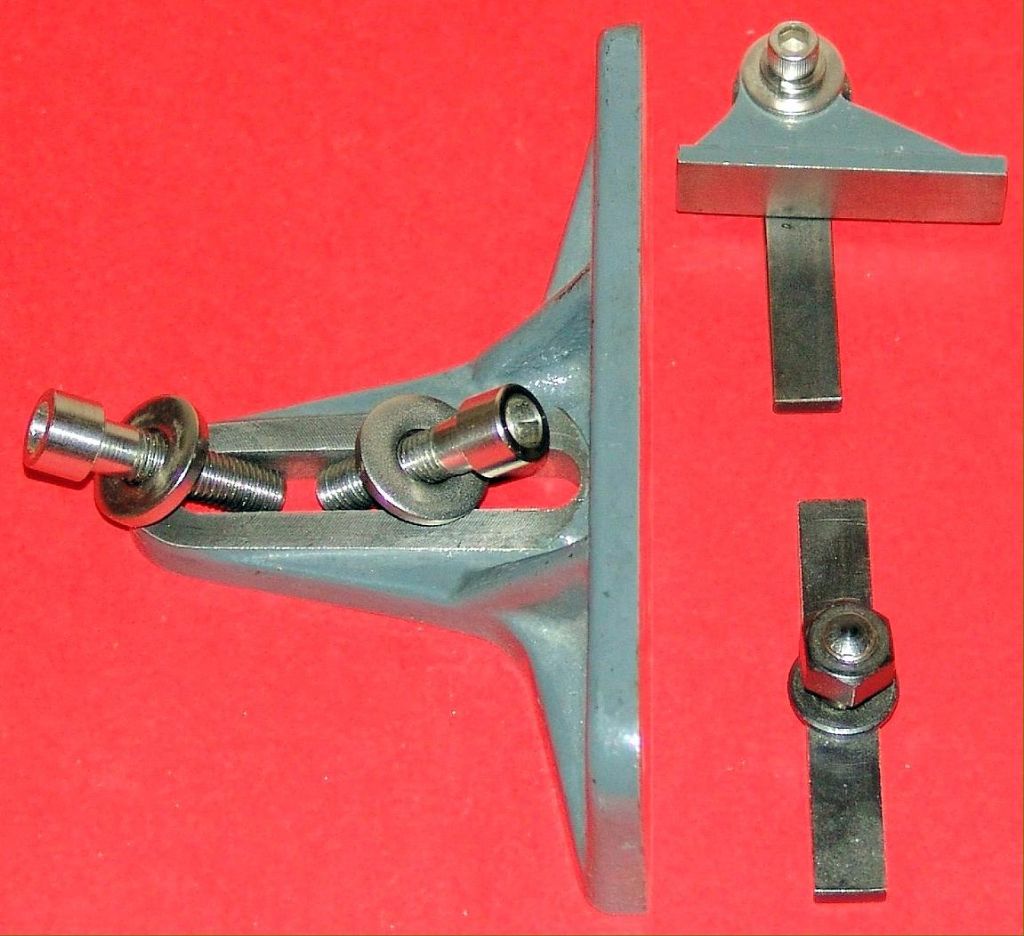

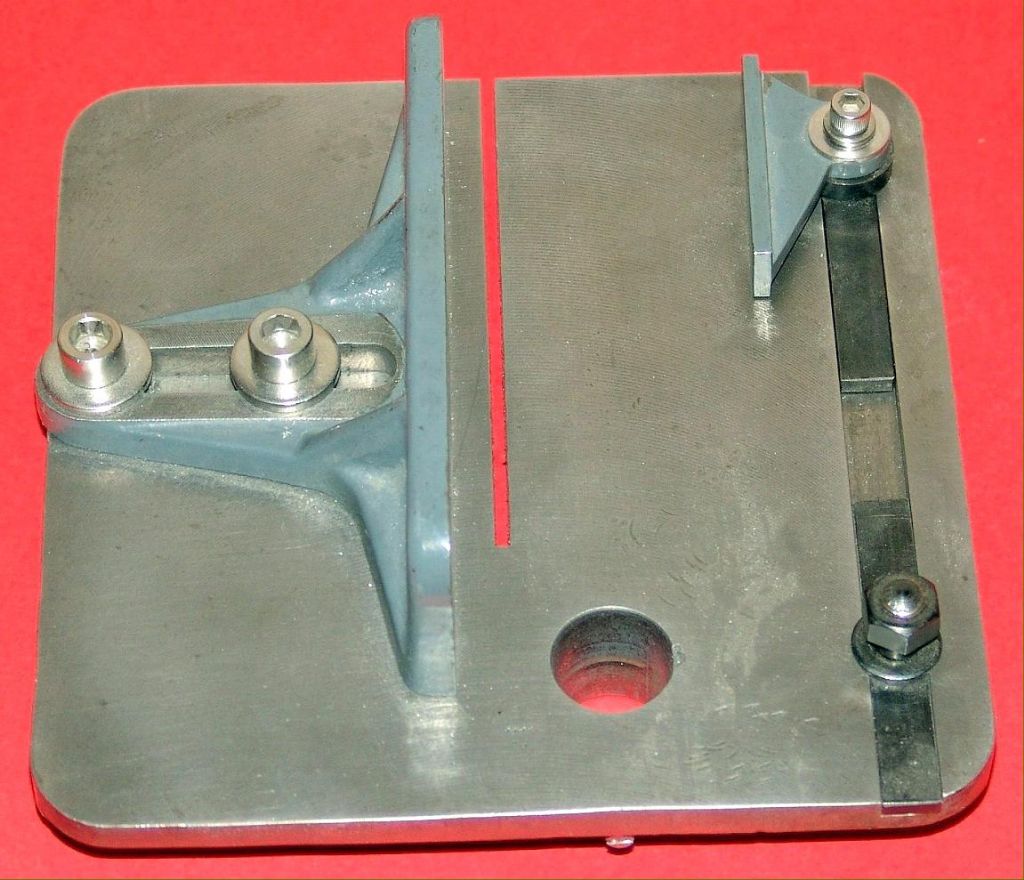

Firstly, it was quickly clear that the stand has to be mounted on the first or last tee-slot of the cross-slide after removing the the topslide. This is so the bottom of the table's pillar can drop below the top surface of the cross-slide, else the table cannot be lowered over the saw.

The problem is then how far you can traverse the table of the saw. The leading edge of the advancing table would only go about 2" past the lathe centreline.

However, if I were to set the table up on the back of the cross-slide facing the operator, I found I could advance the table towards me to the full extent of the table's slot. First thought was that cutter rotation would be wrong – then realised I could flip the blade and run the lathe in reverse. Does that make sense?

Secondly, am I right in thinking the table cannot be used with saws of less than 3.5" diameter, else the underside of the table will collide with the arbor or some part of the tailstock?

After doing these rough setups with a chuck in place, I put the arbor between centres and it was unclear there was sufficient engagement between the driving spur and the arbor. Certainly not enough to 'wire'. Is this usual? Do I need a 'shorter' fixed centre?

Finally, and I'm making my way well down the list here, is it a good idea to 'bung' the hole in the cross-slide after lifting out the topslide? How?

Cheers, Colin

Robbo.