OK, and congratulations for figuring out the niceties of the routine for uploading photos.

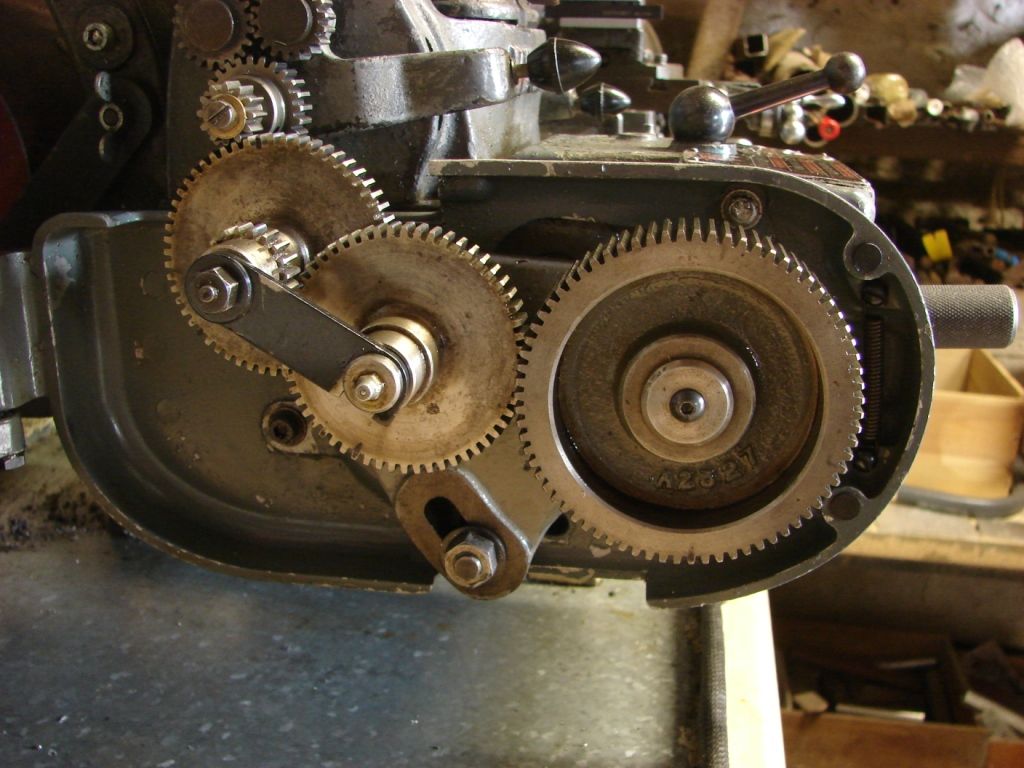

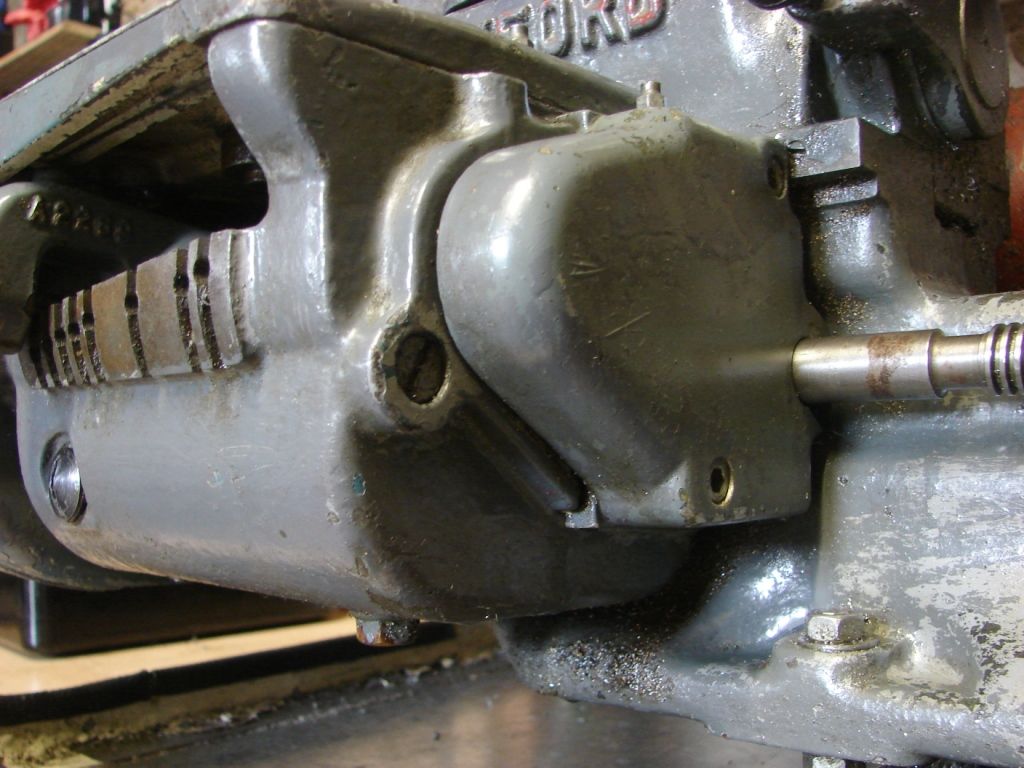

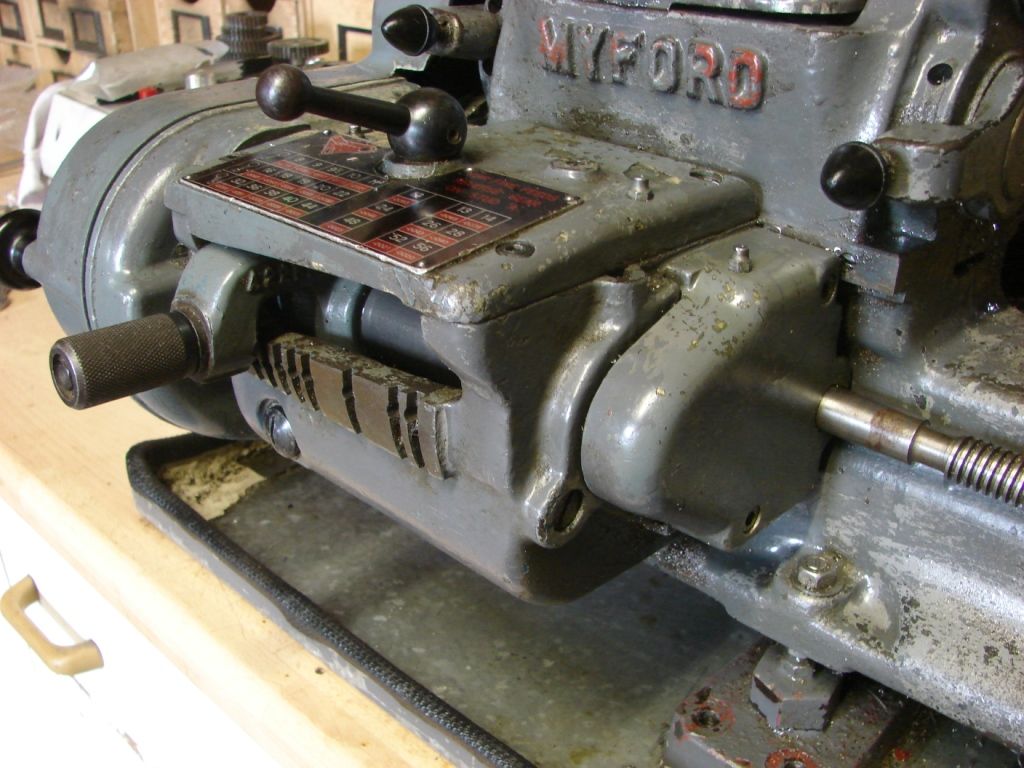

The last but one of your photo's shows the cover plate of the older Mk1 gearbox. The newer Mk 2 gearbox also has a cover, but it has a 2:1 step down gear pair hidden behind it. The import of this is that Myford decided to run the internals of the gearbox at twice the speed of the original design. I would imagine this was a ruse to reduce the torque transmitted by the gears as at that stage of its development the internal gears of the QCGB weren't hardened. Eventually Myford built these gearboxes with hardened gears inside, but that's another story.

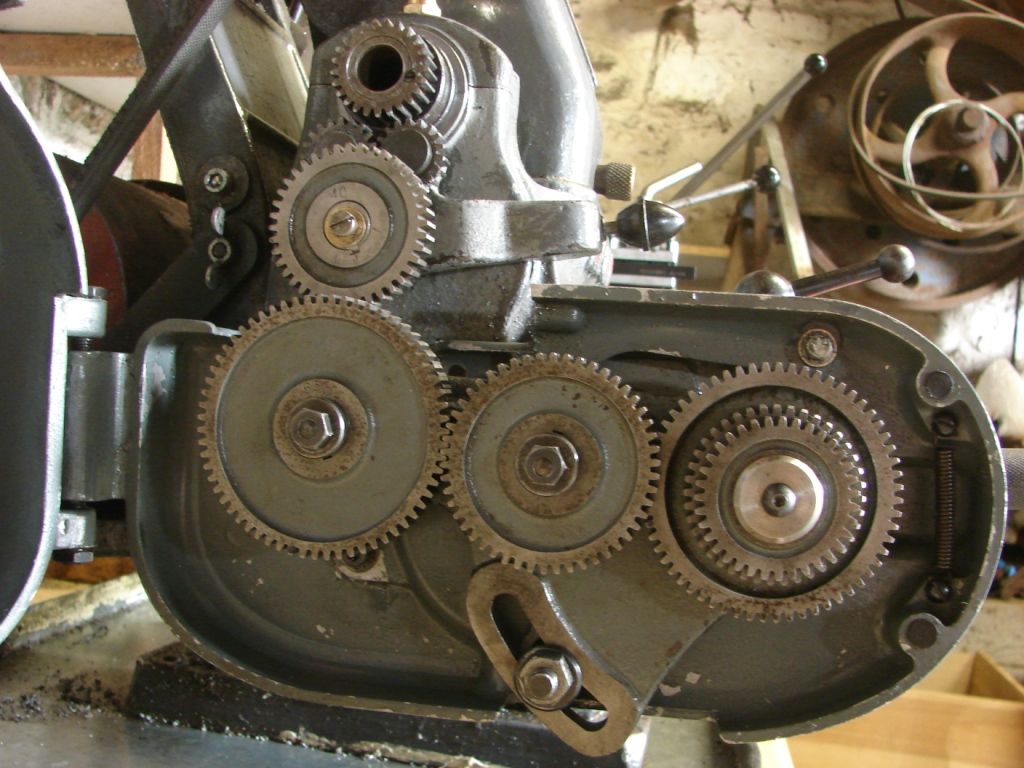

Further evidence of this being the old Mk1 slow speed gearbox is in photo 3, which shows that the mandrel gear is 12 teeth. This gear is 24 teeth when driving the Mk2 g'box. I'm assuming that the set-up with the two 51/17 gears between the mandrel and the broad 72 T g'box input gear cuts TPI's as detailed on the g'box top label – i.e. the imperial settings all work out, it's just the metric conversion kit which has screwed things up.

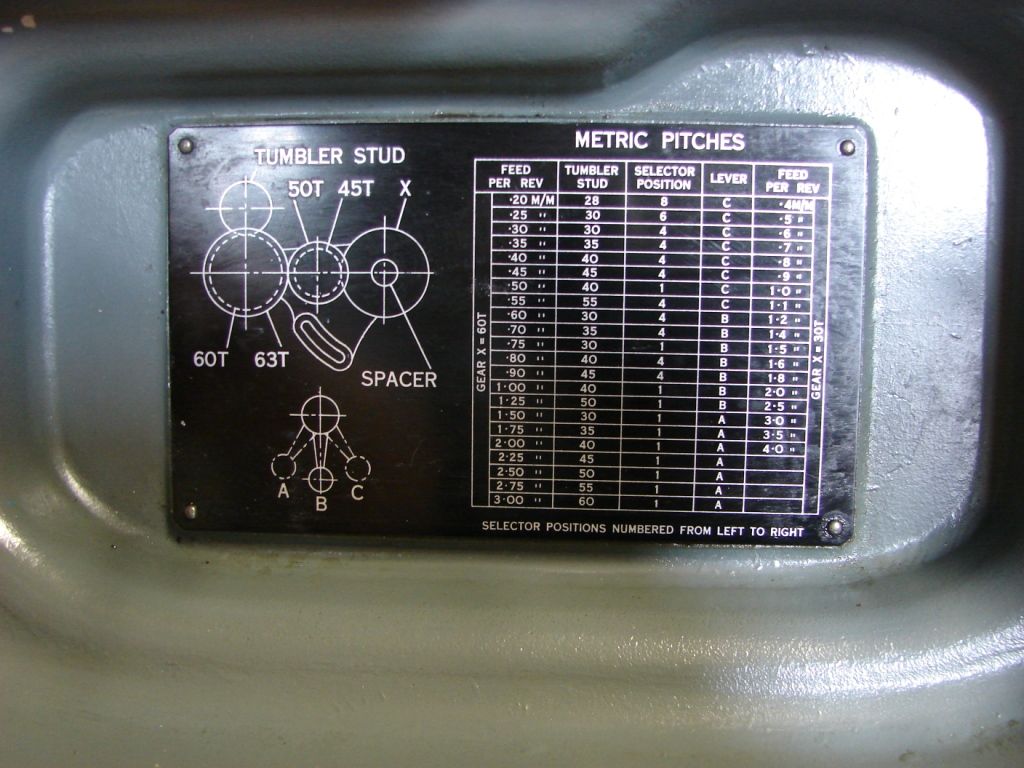

Unfortunately it seems that Myford only ever made a metric kit for the Mk2 g'box, though there were undoubtedly two versions of this kit and so there are two different label diagrams with the accompanying table of gears to use. This appears to have been a cost cutting exercise – that later kit has one less gear in it. AFAIK you can use the banjo with either selection of gears.

If you can fathom out a way of reducing the input speed of the g'box by half I think you will have solved the problem you have encountered with cutting threads of twice the pitch expected. A 120T gear on the leadscrew would do it, but I'm not sure it'll fit in the space available.

There is another solution, for which you don't need the metric kit at all, just a different gear mounted on the mandrel. This is the subject of a whole slew of correspondence on the forum, and if you would like to read up on it this is a good place to start. There is some more related stuff here where the OP was trying to cut imperial threads and finding he was cutting an apparently arbitrary TPI.

If you decide you want to experiment with the idea of changing the tooth count of the mandrel gear let me know, but DON'T buy the 33T and a 34T gears mentioned in the posts I have tagged, they are no use to you and will give you the same problem you presently have. I will explain further in due course though the details are in the threads referenced above.

Hope this helps, in due course do please let us know how you get on.

Best rgds Simon

P.S. This is also relevant, more of the same.

edited for post script

Edited By Simon Williams 3 on 09/09/2023 14:26:05

john beattie.