Well, with a combination of help from here, a deep re-think, a reset to factory settings and a night's sleep later and it's sorted. Everything is back together and working as it should. Except I have mislaid the 4mm key that drives the spindle gear. It would be the smallest one, too. I'll have to wait until Monday when the key steel I've ordered arrives before I can do any cutting under power. Manual feed only for the moment.

A big thank you to everyone who responded either on here or by PM for your help.

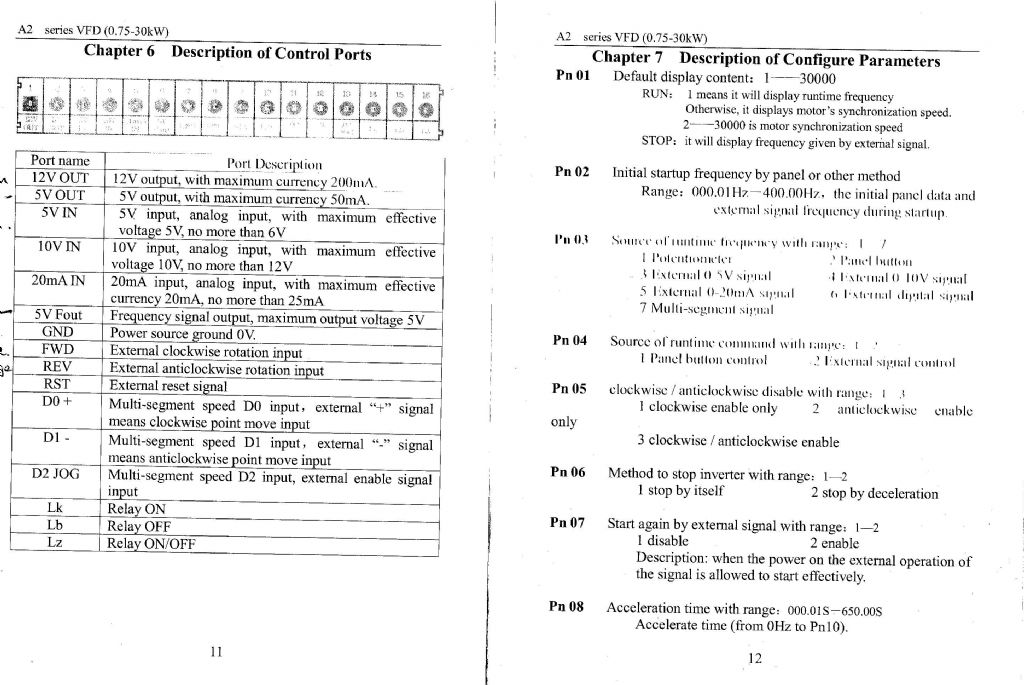

For the benefit of anyone following in these tracks, these are the settings I used with reference to the manual page 9 in Peak4's post:

Pn01 = 1 Displays instantaneous frequency

Pn02 = 50 Starting (base) frequency

Pn03 = 3 Selects remote pot wiper as source for frequency control

Pn04 = 2 Selects remote forward/remote switch for direction selection

Pn07 = 2 Enables the start again function from external source

Pn08 = 2.5 Seconds My choice of acceleration to speed – I always reduce to zero speed on the pot before switching off.

Pn09 = 2.5 Seconds. Deceleration time see previous note

Pn10 = 60Hz Maximum frequency set in the software.. Again, my personal choice to prevent chuck overspeed in highest gear ratio.

Pn12 = 50Hz. Motor rating frequency

The rest are as per the manual.

Remote wiring connections reference page 5 of the manual referred to above:

Potentiometer: "low" side – to GND, "high" side to 5V OUT, Wiper to 5V IN

Forward/Reverse switch: GND to one side of the switch, the relevant lead to the respective FOR and REV terminals on the VFD.

Hope that helps someone.

John

SillyOldDuffer.