Alan,

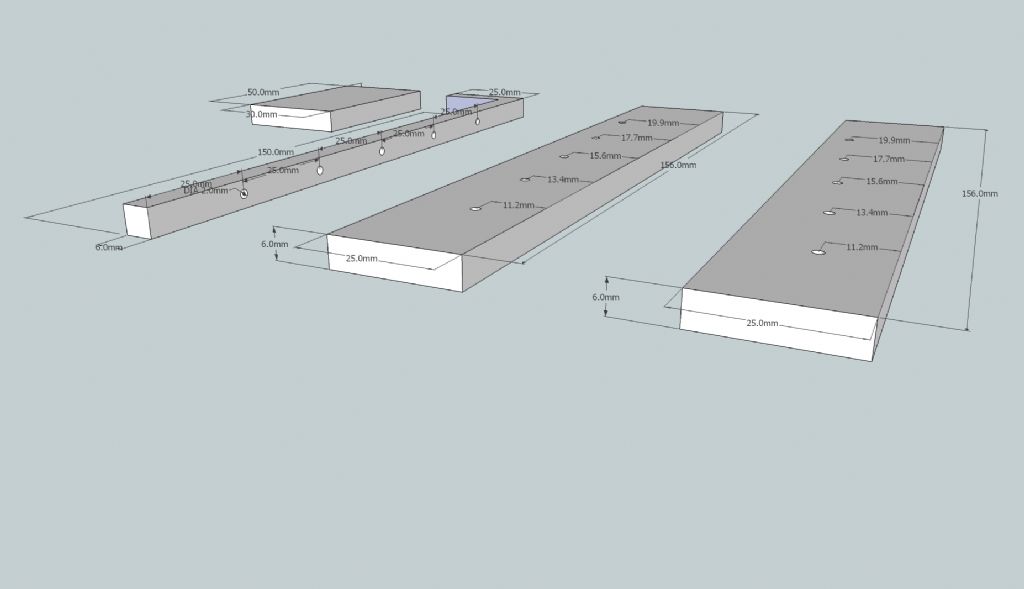

The reason why several of us have suggested gauge plate is partly because it is hard enough to stand up to a fair amount of wear, even without being hardened – but mainly because it is dimensionally very accurate. Most metal sections of a more mundane pedigree are often not too close – mild steel, for example, is often a couple of thou undersized, and also can be not as crisp in its cross-section. The only way to get it spot on is to start with a larger section and mill it down to size – and then (with bright sections) you can run into problems with distortion if you don't stress relieve it first. Black MS is rather better in this regard.

Of course, one thing for you to check is how precise is the section of your plastic. If that is slightly under nominal size, then you might find MS or aluminium in commercially available sections would be OK. MS would probably survive a few hundred holes without hardened bushes, if you are careful; aluminium probably wouldn't.

I have a miiling machine with DRO, but I'm too far away from you; I really think you need someone close so you can get together 2-3 times to get everthing checked out.

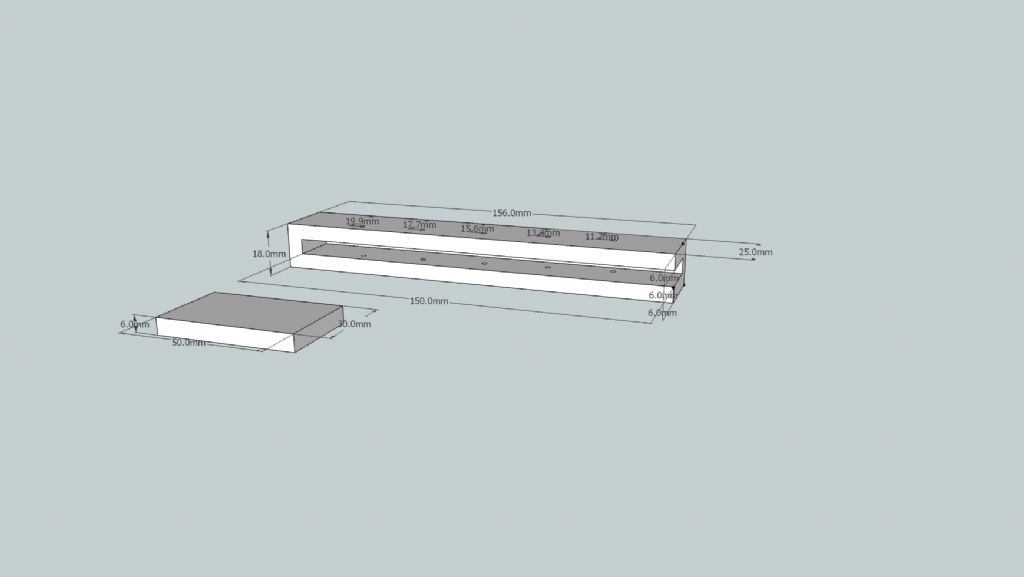

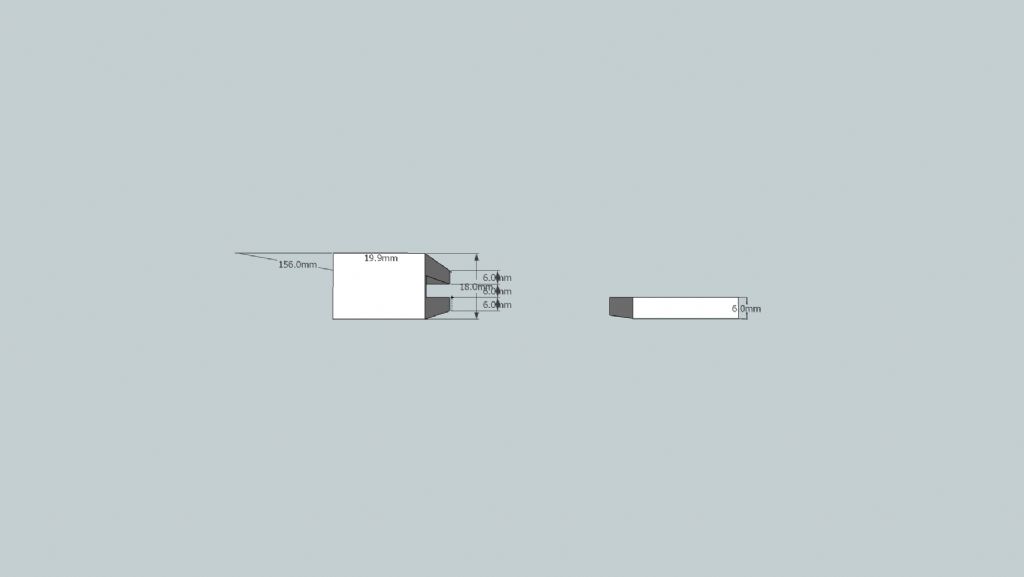

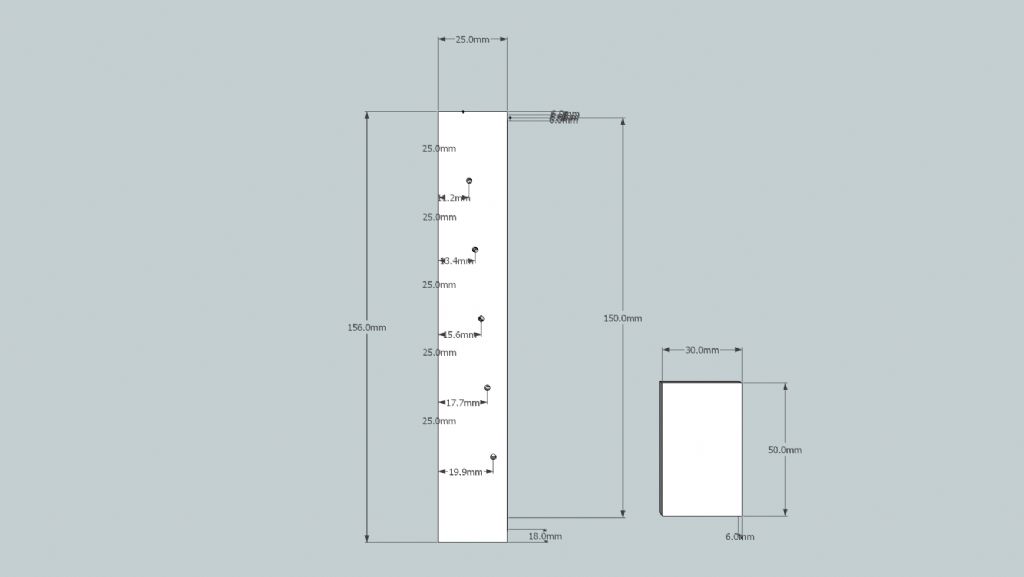

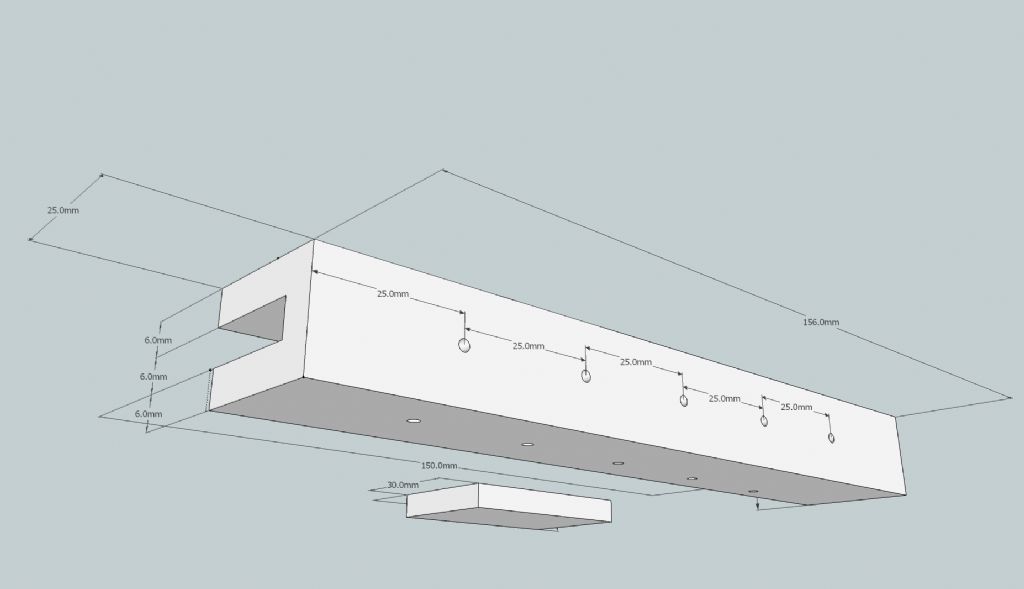

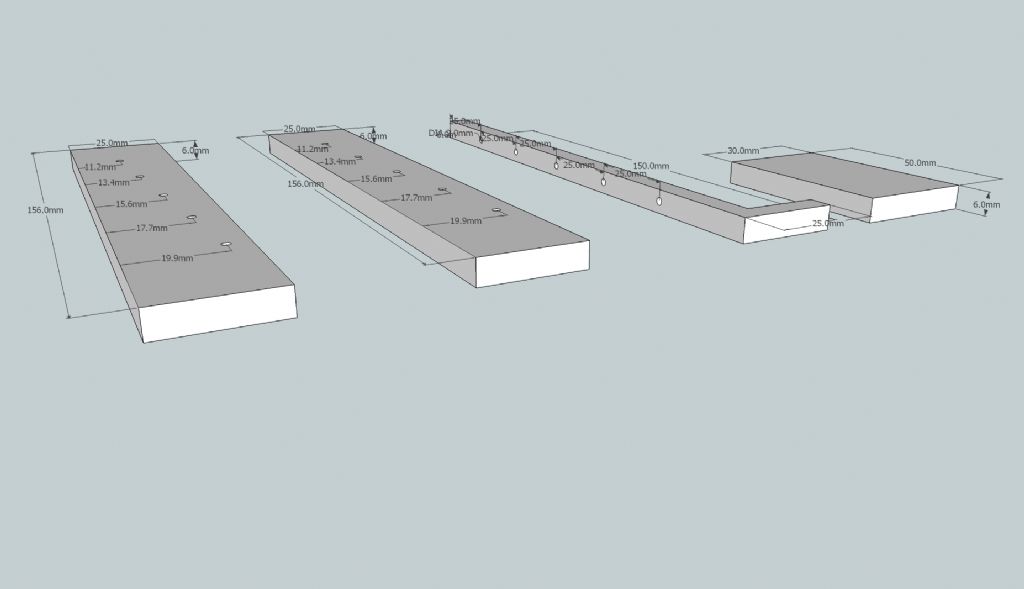

One afterthought – you might like to consider adding a metal section – say 6 mm square – at the base of the jig so that you can hold it in a machine vice without obscuring the holes or the slot for the plastic sections. As designed, you may have trouble in that respect.

David

Edited By David Littlewood on 24/11/2012 19:16:02

Hopper.