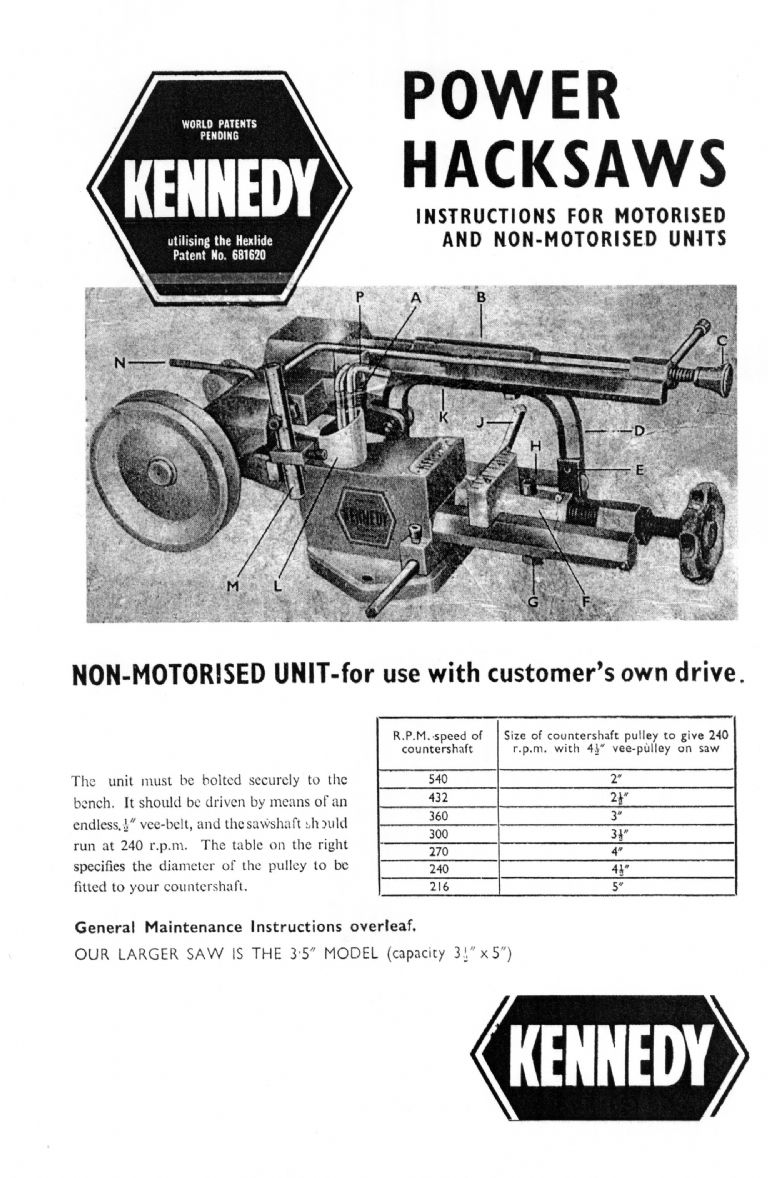

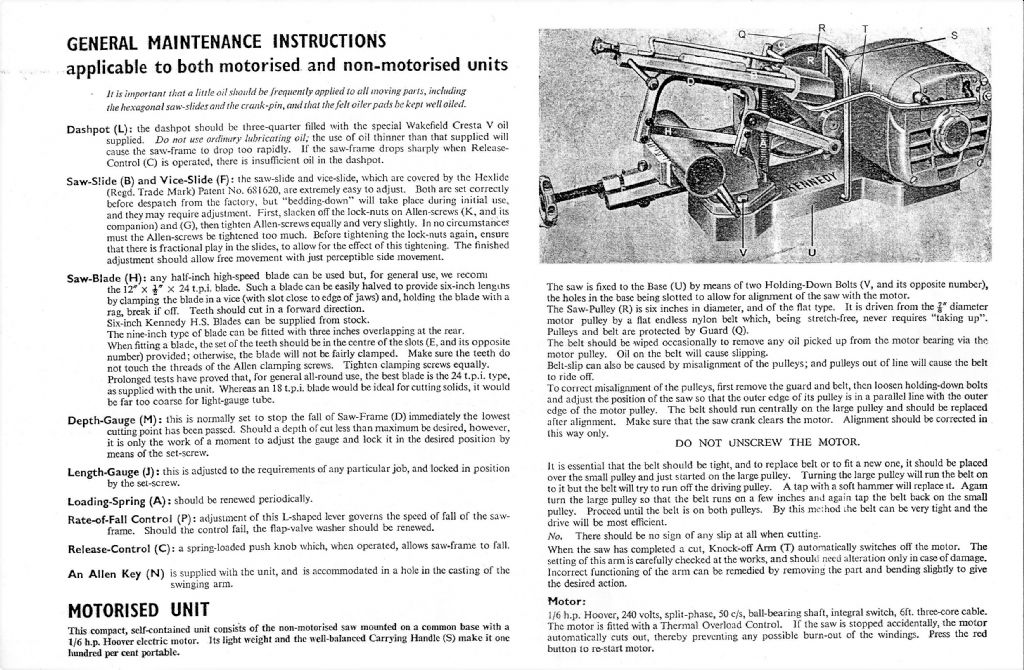

Can someone please measure the diameter of large driven flat belt pulley and read off the motors rpm if legible? – I gather the motor's shaft was used directly as the driver pulley so I can measure that.

I'm over the moon to have picked up a model 60 (I guess) as I've been wanting one for years. Its missing its driven pulley, and needs a good strip and clean.

I've got a handful of Vee pulleys sitting about so I'd like to use these, however given that the original arrangement used the motor's spindle directly, to drive quite a large pulley, I think I'm going to struggle to get the reduction I need inside the standard guarding which I would like to try and retain because its quite nice!

In addition, the standard 1/6 horse motors are known to be feeble, so ideally, I'd like to achieve a slightly higher reduction than standard or run a lower speed motor which then gives me ample room under the standard guarding. If say the motor is a pretty standard 2 pole 2700-3000 rpm, I should be able to easily source a little 4 pole and halve the speeds.

I'd be grateful of any advice, tips, parts diagrams, manuals or a word from anyone who shares an interest in these.

All the best,

Russ

peak4.

peak4.