The CL430 (and the CL500M) was discontinued some time ago.

The original couplings might be sinters, so more liable to shatter,than plain steel.

This feature might act as a fail safe, to protect other parts in the power train.

LONG shots

Chester sell the Model B which looks iike the Clarke CL500M (The lathe with the milling attachment)

Although the Model B may be the higher centre height version, there is the possibility that it might use use the same coupling.

They might have spares.

Warco used to sell similar machines. But discontinued them a long time ago. But might be worth asking if they have any as old stock.

The part that you seem to need is listed in the Clarke Manual as No. 25 in the Gear Train section, Part no HT300030025

If you have not got the manual, and parts list, send me a PM with your E mail address, and I’ll E mail you copies of the CL500M one.

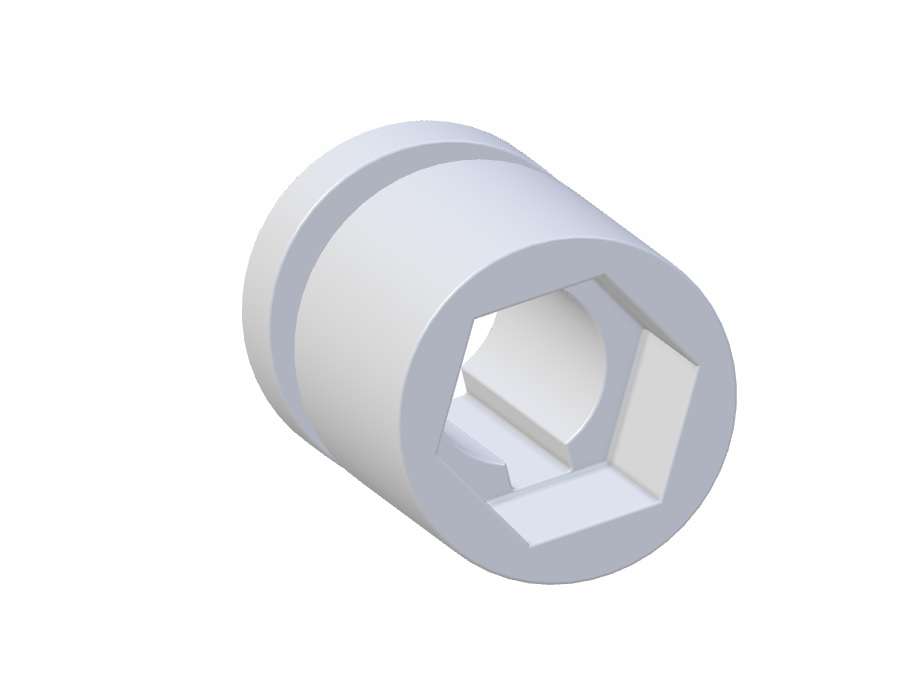

If the coupling has hexagonal recesses, would it be possible to fabricate a coupling by shortening and brazing/welding together two capscrews with the appropriate size hexagon?

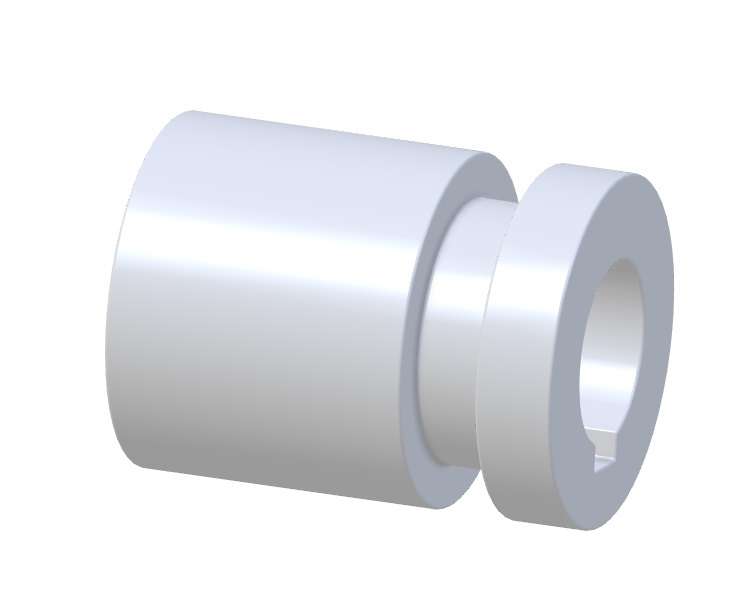

As a last desperate resort, you could turn up a thick walled sleeve (Preferably with two two counterbores with a blank section in between, for axial location) which is a tight fit over the corners of the hexagon, then drill and tap holes at 120 or 60 degree spacing for grubscrews to bear on the flats.

Ideally the sleeve should wall be thick enough to allow 1 diameter thread engagement for the grubscrews.

Another “Go for broke” method, might be to buy two good quality single hexagon sockets (Probably won’t matter whether 1/2 or 3/8 drive) shorten both, and turn a deep chamfer on the new ends. Then weld the two together, to make the replacement coupling.

The chamfer will aid weld penetration, but clamp in a piece of angle iron to maintain alignment.

If the weld stands proud and liable to foul anything, you can always turn it down to clear.

Obviously the feed will have to be manual!

Probably the alignment of the hexagons may not be vital, although ideally keep in line, just in case.

Howard

kamiennik.