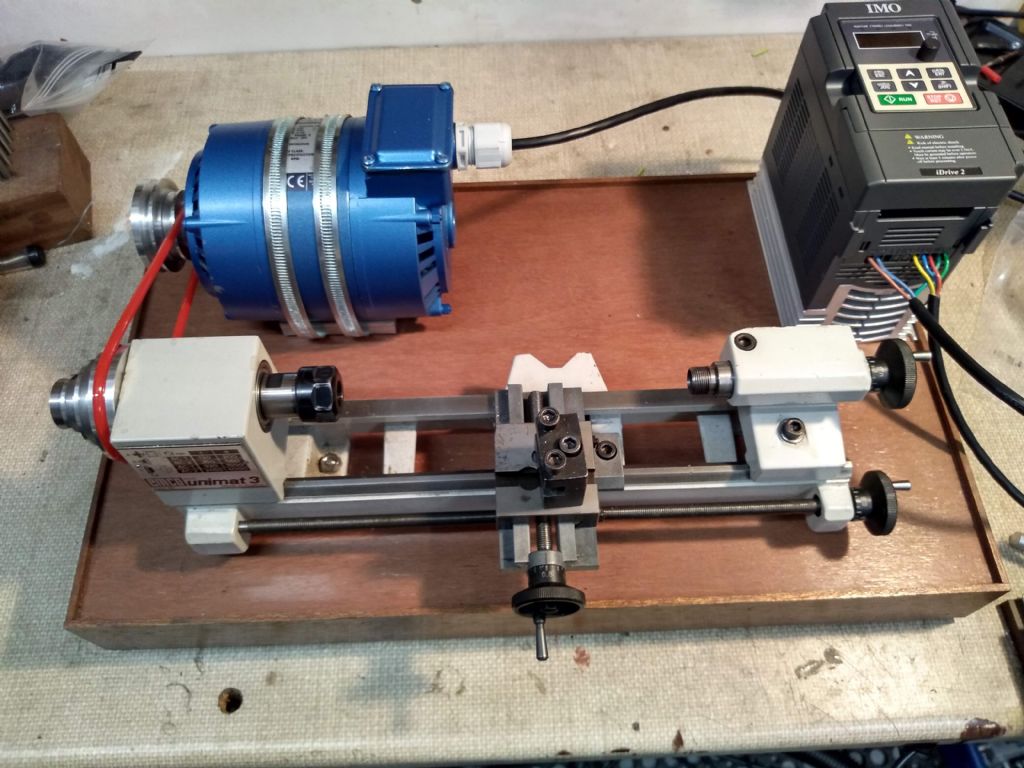

Hello fellow model engineers. I see that others use a Unimat 3, I bought one 40 years ago in Holland, and when returned to the UK discovered the voltage difference caused the motor to overheat, so with the help of Rex Garrod, (robot wars fame, etc) I changed the power to a 0.5kw DC motor, with speed controller, I made new toothed pulleys and swapped to toothed belts. It is now capable of reducing a 1" brass bar to 0.5" in a single pass. As for the oilite bearings on the verticle milling attachement, I had Manganese Bronze of Ipswich do a refit when I had 0.3mm end slop, they sent it back with new bearings and 0.5mm end slop, I'm sad to report, so I made a new larger head, 40.000mm turned slide, stuck in 2 big taper bearings, and put a 0.3hp 3 phase motor on, with speed control, and reverse, you can't stop it with your hand when it goes slow, drills down to 0.3mm lovely, managed to get it to 1/000mm accuracy making alloy adjustable head. I have used the machine an awful lot, have reground the bed a few times…I actually have 3 of the machines !! Used mostly for master patterns for Matchbox and Corgi, Scaledown, Border Fine Arts etc.

Former Member.