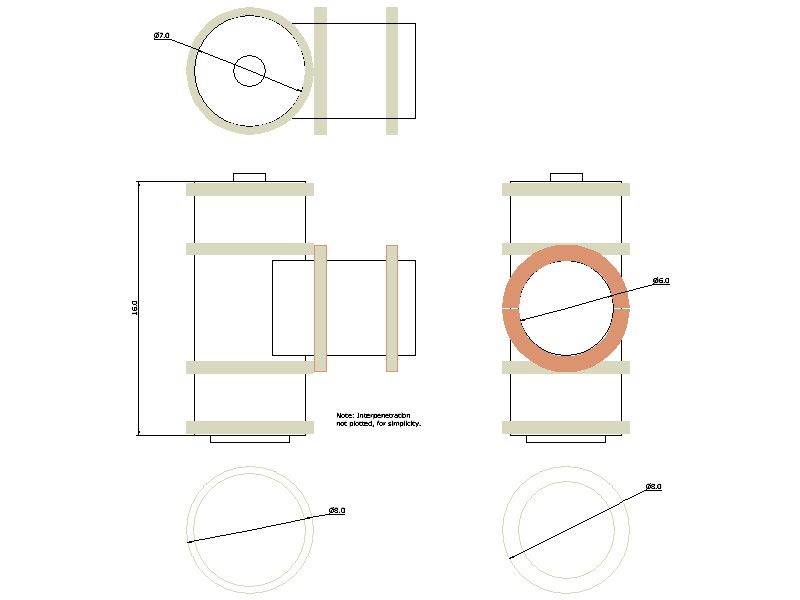

For boiler cladding crinolines.

(Yes I know a proper drawing would help but I don't have one! The simplified drawing and photo below might explain things.)

'

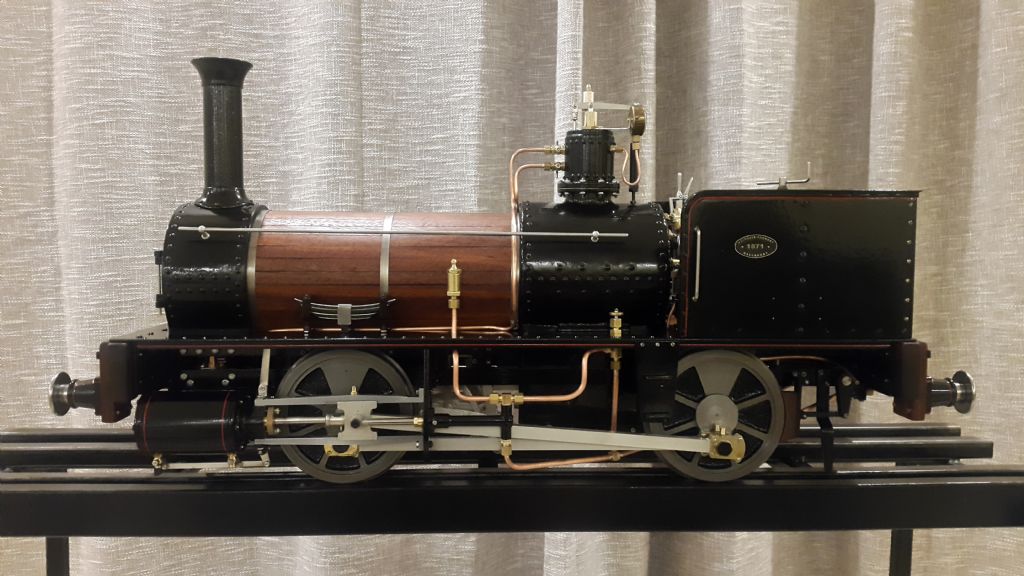

My wagon's boiler is an unusual shape, a T-piece with 7" o.d. X 16" high cylindrical outer firebox, and a short 6" o.d. horizontal barrel at half-height. The latter's barrel diameter is level with the chassis rail tops.

The barrel enters for about 1/2" into the 8" o.d. smoke-box, on which a ring of "rivets" (M3 round-head cap-screws) holding the annular channel adaptor-plate narrows the cladding overlap to about 1/4" .

It also needs a cradle fitted to an inverted-arch chassis cross-member, below it, for support if the smoke-box is removed. (as it would be if I needed lift the boiler from the vehicle.)

So cladding is somewhat awkward!

My thoughts:

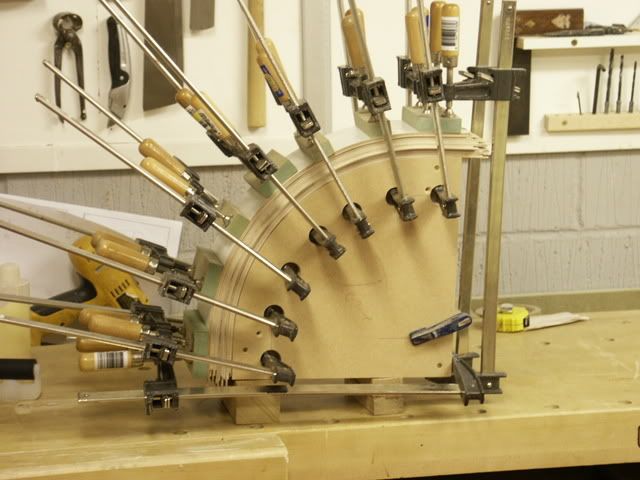

A wooden half-circumference cradle on the cross-member.

Two rings of 8" od X 6" i.d. on the barrel; the front one helping support the cladding sheet's overlap on the smokebox.

Two pairs of rings 8" o.d. X 7" i.d., each pair above and below the barrel, on the fire-box.

So 6 rings and one half-ring.

Question:

At a working temperature of about 200ºC (90psi), how would these cope:

– ordinary soft-wood, the rings made in 2 or 3 layers of sectors overlapped, glued and screwed together on their faces, and so the grain on each part is not far off concentric, for strength.

– exterior-grade plywood, possibly 2 or 4 layers depending on layer thickness,

– MDF

– ??

All finished turned sub-assemblies then soaked in preservative.

Nigel Graham 2.