I wonder about the skill-level argument's validity.

I am not likely to use any form of CAM work; be it a putter-onner or a taker-offer of material. I use TurboCAD but my workshop is all manual-operation; and I can't learn CAD enough for pretty 3D pictures of what I want to make.

'

Nevertheless, I don't see an intrinsic problem with using such methods in model-engineering, for two reasons.

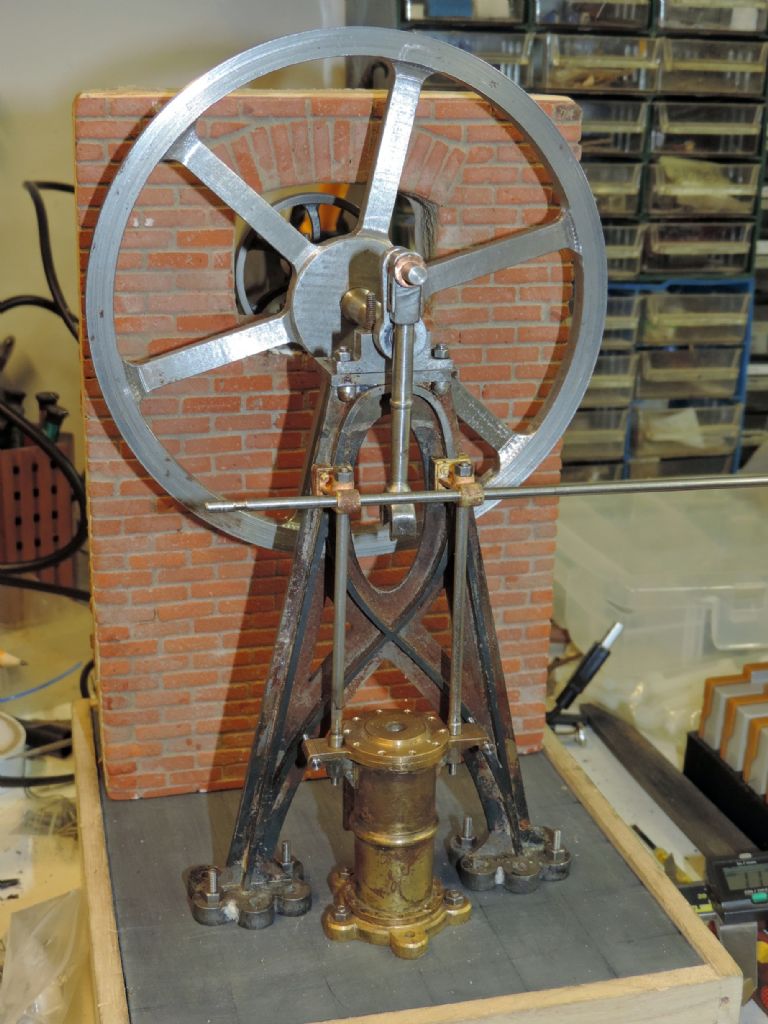

Firstly, the aim is to make something by one's own hands using mechanical-engineering knowledge and skills; and not necessarily model-engineering by the definition of a fully-functional scale model. A clock, microscope, or machine-tool accessory is not a model but the necessary tools and skills overlap with those needed to build, say a 5" gauge locomotive or 1/4-scale aero-engine.

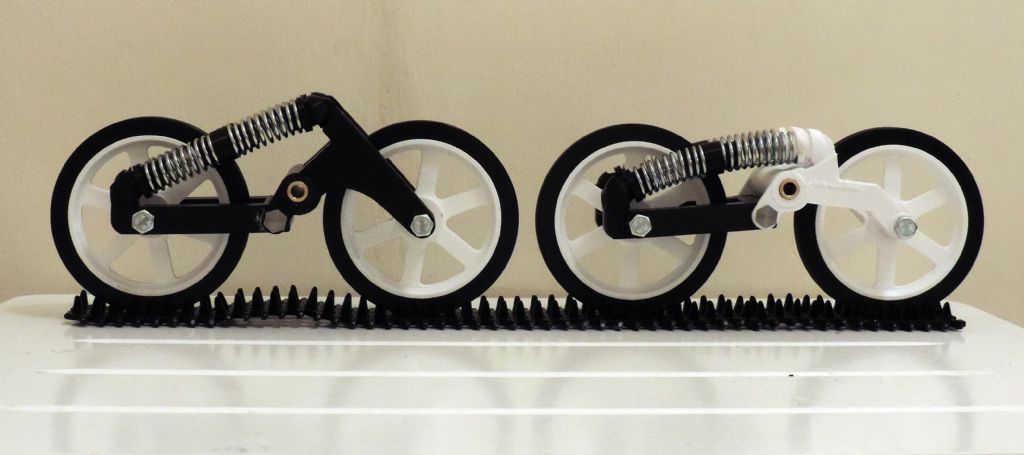

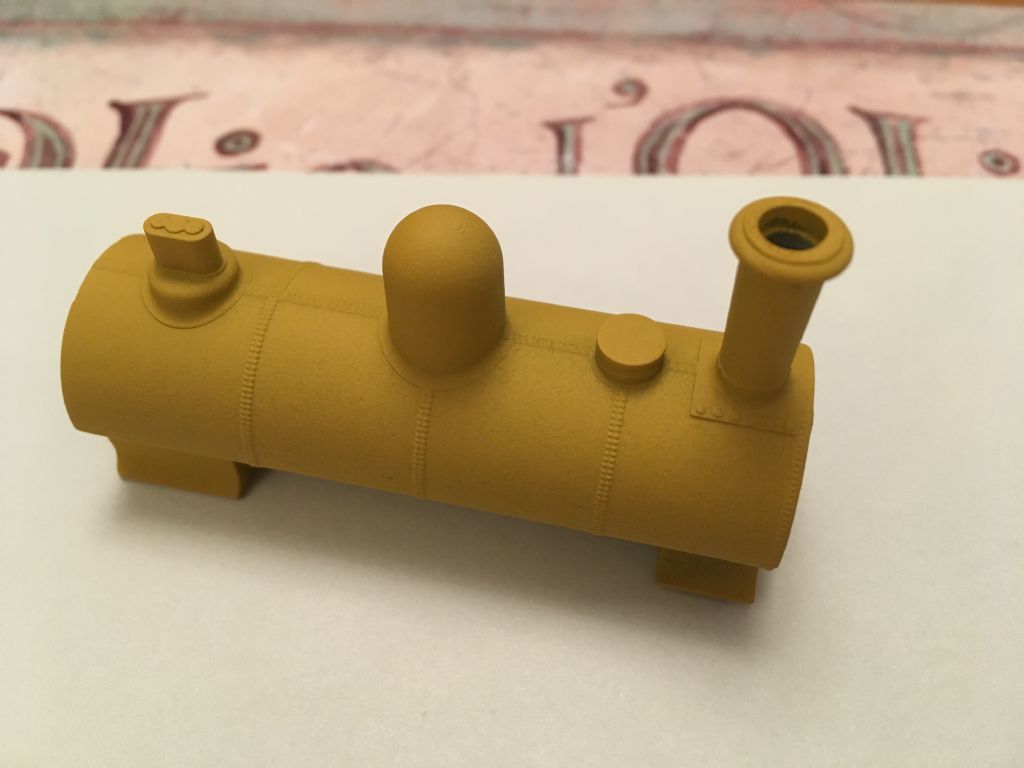

Secondly, CAD / CAM techniques are an end to that making. They are tools, just as the hacksaw, file and centre-lathe are tools. They are also tools requiring considerable ability to learn to a level suitable for making the clock or locomotive parts.

'

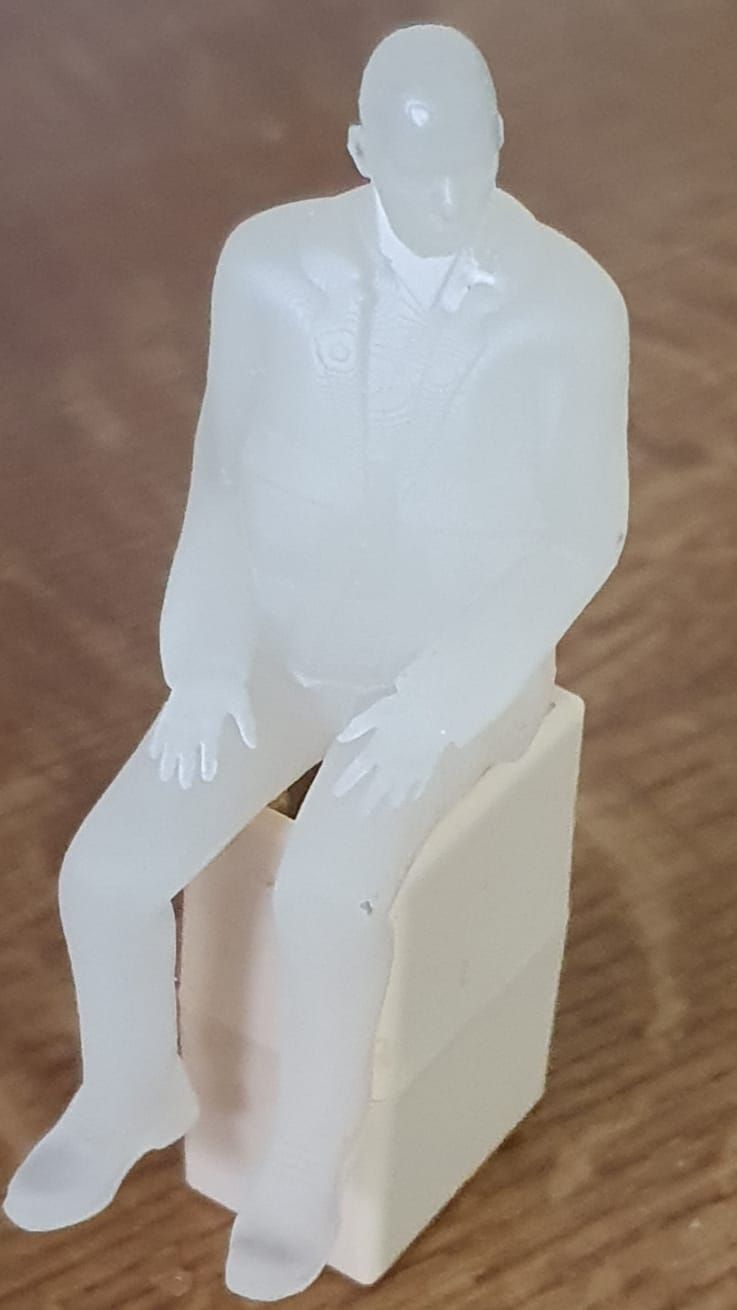

I would agree that the craft hobbies should not be so diluted by computer-worship that they are devalued to merely justifying the computer or leading to inability to design and make anything; but I propose CA-Draughting and 3D-printing can be valid, high-level auxiliary skills as a part of model-engineering in all its variety.

Applied intelligently and not just as an end in themselves, I see adapting methods used in the modern engineering industry can extend the range of skills we use in model-engineering. Not diminish or replace them. It's still right to be able to saw and file a piece of steel to a line, and draw-file its surface to a beautiful satin sheen.

Mick B1.