I have a Prusa MK3.

I have designed engines by making drawings manually on a drawing board, using AutoCad for 2D drawings, and 3D modeling using Solidworks.

I have made patterns by hand in wood and steel, and have made engine parts on the lathe and mill from bar stock. I have also made patterns on a 3D printer.

I have made castings and machined those.

The reason I use a 3D printer and Solidworks is that I can make the same patterns I would normally make by hand, but can make then more accurately and sometimes more quickly.

It is easier to get the srinkage factor uniform across a pattern if it is 3D printed.

So I recommend learning to do things by hand, but once you have that mastered, then using computers and 3D printers just speeds things up.

My dad was old school, and he would never consider using a computer for anything except a boat anchor.

I am required to use computers and software for work, so it is a natural thing for me to use them, and I am fluent in them outside of the hobby.

To each his own. Its whatever makes you happy.

I started using Solidworks in 2012, and not to many were using 3D at that time.

Many more of those same folks I notice now use 3D modeling, so it seems to be a trend.

I do like to be able to do things by hand, because there is a touch and feel aspect that you can't get with computers and software.

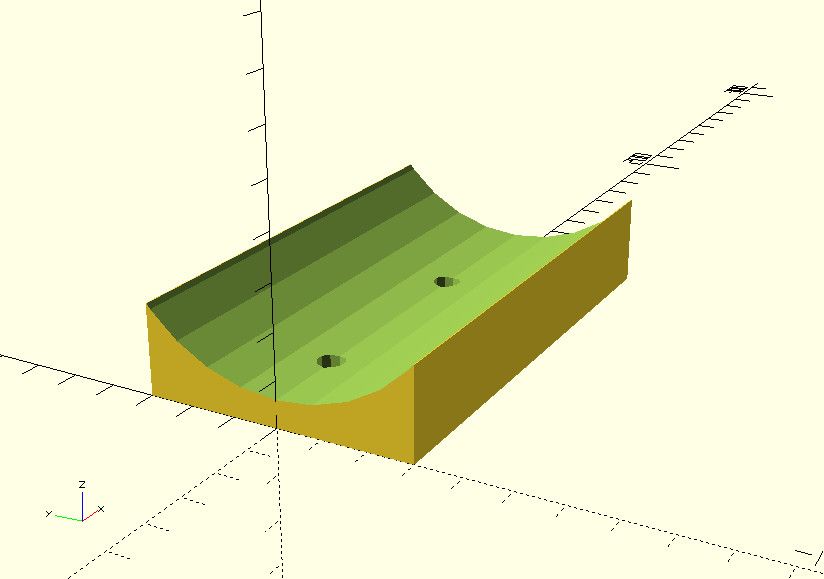

Using the CUT command in Solidworks is much like machining the real metal (virtual machining I call it), and it helps conceptualize how I will machine a part.

I also assemble the 3D components and run them virtually, to test for inteferences, etc.

If the model won't simulate in 3D, then it won't run in the real world either, so that is a helpful verification step before I start cutting metal.

I don't use a CNC, but I see a 3D printer as being very similar to a CNC.

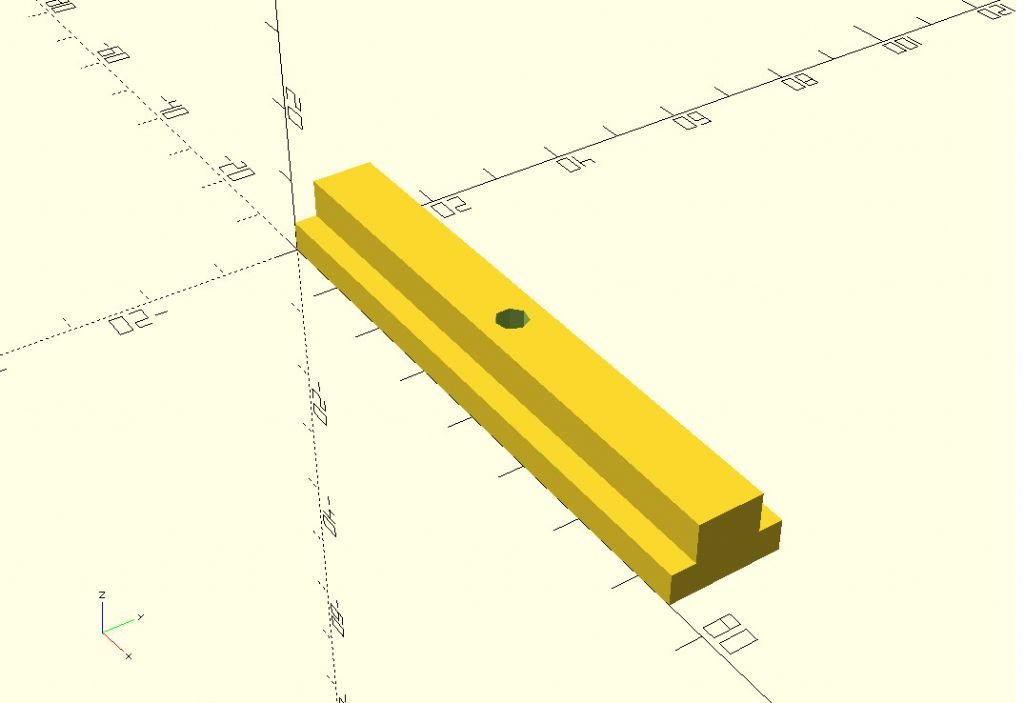

I don't have plans to "go CNC", since I find a 3D printer much more useful for pattern making, especially with hollow items, where I can use a 3D printed pattern also as a core box.

I guess it really just boils down to time. I can start a 3D print, and let it run overnight, and in the morning (if all goes well) the pattern is sitting on the printer bed.

I can design with software faster than any other method I have available.

Use the tools you have available I guess.

Edit: On a side note:

I am having lifting issues with the Prusa bed.

Anyone have a solution for that.

I have not tried the purple stick glue yet, but need to try that.

.

Edited By PatJ on 29/01/2021 10:28:17

Edited By PatJ on 29/01/2021 10:28:37

Edited By PatJ on 29/01/2021 10:30:46

Mick B1.