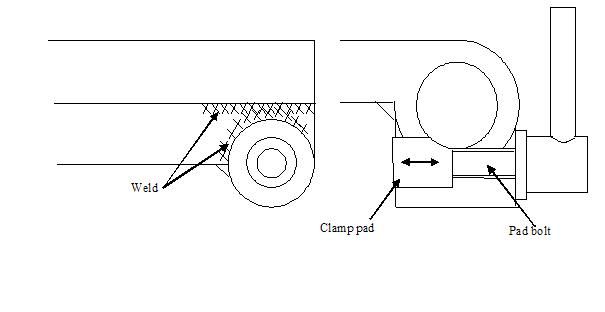

This weld repar – was it your intention to preheat before welding. That is fairly normal with cast.

Having said that, it’s not always necessary and you can get away without sometimes. In the same way as you can use a mild steel rutile rod perfectly well on alot of repairs. Not ideal but it depends on the criticality of the job.

At the risk of telling my granny. With any weld, like any other “casting” process the liquid metal goes onto a solid substrate. It then solidifies and contracts and sets up stresses. The problem with chunky bits of cast, or where you have changes in section, is that the tensile loads created by cooling often/can exceed the tensile strength of the cast and it either cracks as it cools, or the residual stress causes a break in service at a very low applied load. (Cast is very prone to this because it is not very ductile, so its not very accomodating in that respect.)

Peening is an option but clouting cast in some circumstances is either not a good idea or not practical anyway. you could shot peen of course, or something similar.

With a rather thin section and a bigger body, it might be wise to look at the business of prehating, and see if you cant get a decent wedge of heat in there before welding. If this were an easily replaceable casting one could afford to be less “by the book” perhaps?

The actual detail welding of cast with MMA is not difficult of course – it welds quite easily. Its the other bits that go with it that deserve a look.

Edited By mgj on 14/02/2011 09:53:06

John Coates.