Posted by Jake Middleton-Metcalfe on 14/02/2023 14:05:28:

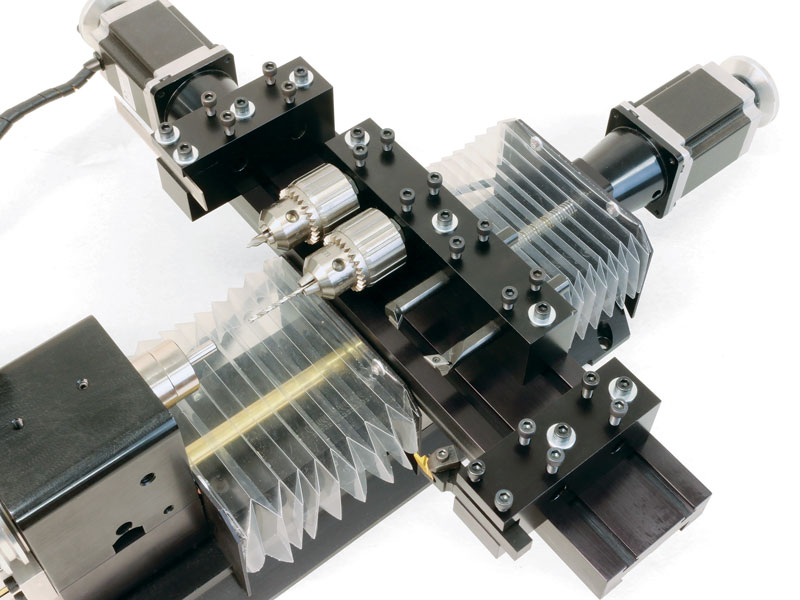

As mentioned in previous post here is an image of a concertina button – made in two parts

No idea, but presumably there is a male thread on the white piece and a female thread in the silver piece holding the two together?

It does not look like a capstan set up would save much time over what can be done with existing gear such as form tools and lever tailstock if you start off with material of the correct OD. You might look at making some capstan-lathe style roller boxes to mount on the tailstock turret. These consist of a pair of small rollers to hold the work steady while a pre-set cutting tool turns the job down to the reduced diameter as it is feed along. Then a miniature Coventry diehead type thing to do the male thread and a tapping head to do the female thread quickly without smashing the tap into the blind hole.

The domed end on the silver piece could be put on using a combined parting tool/form tool as the final operation. Will need a bit of polishing afterwards to finish it off to such a standard but you are going to have to do that anyway.

Making bolts is definitly lever tailstock territory. Or using hexagon stock and a multi-stop carriage stop you can have a stop to set the amount of bar sticking out, then the amount of shank turned down (or roller boxed down) then apply thread with die head in tail stock. Then part off using carriage stop again, putting the chamfer on the hex halfway through the parting process, or make a combined parting/chamfering form tool.

The cross hole is a bit special, especially in the workholding aspect. Special jig required etc. But time could be saved by making a drill bit with a surrounding hardened silver steel sleeve shaped as a countersink cutter, so all done in one motion.

Edited By Hopper on 15/02/2023 00:50:51

Nigel Graham 2.