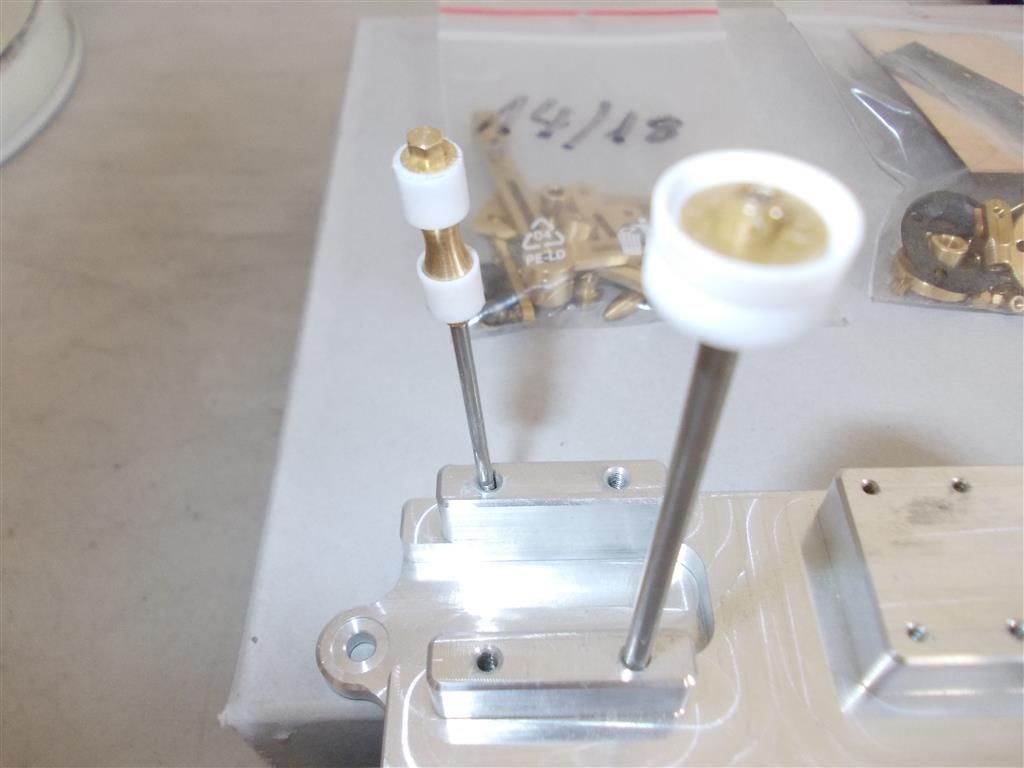

None of my suppliers has stainless steel rod that small. Apparently the 2mm rod was reclassified as wire a few years ago and this has caused problems for some reason. I will have to buy stainless steel from Hong Kong. One of my suppliers said that he now uses 2mm brass rod for piston rods with no problems so I will consider that too. Any thoughts on that ?

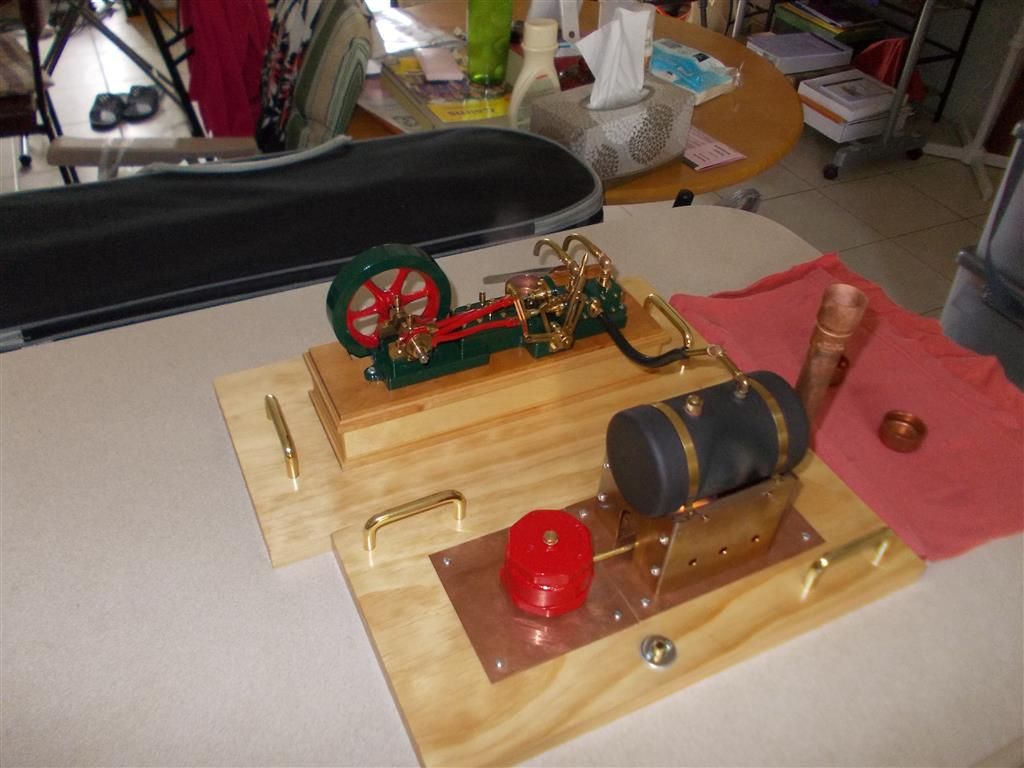

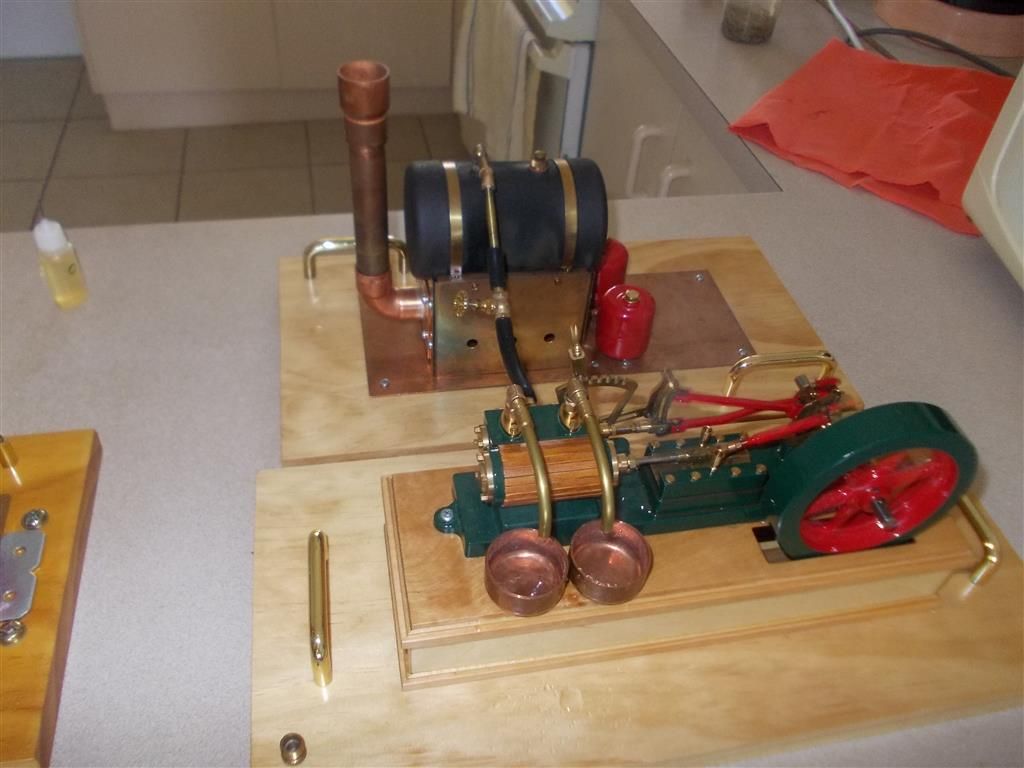

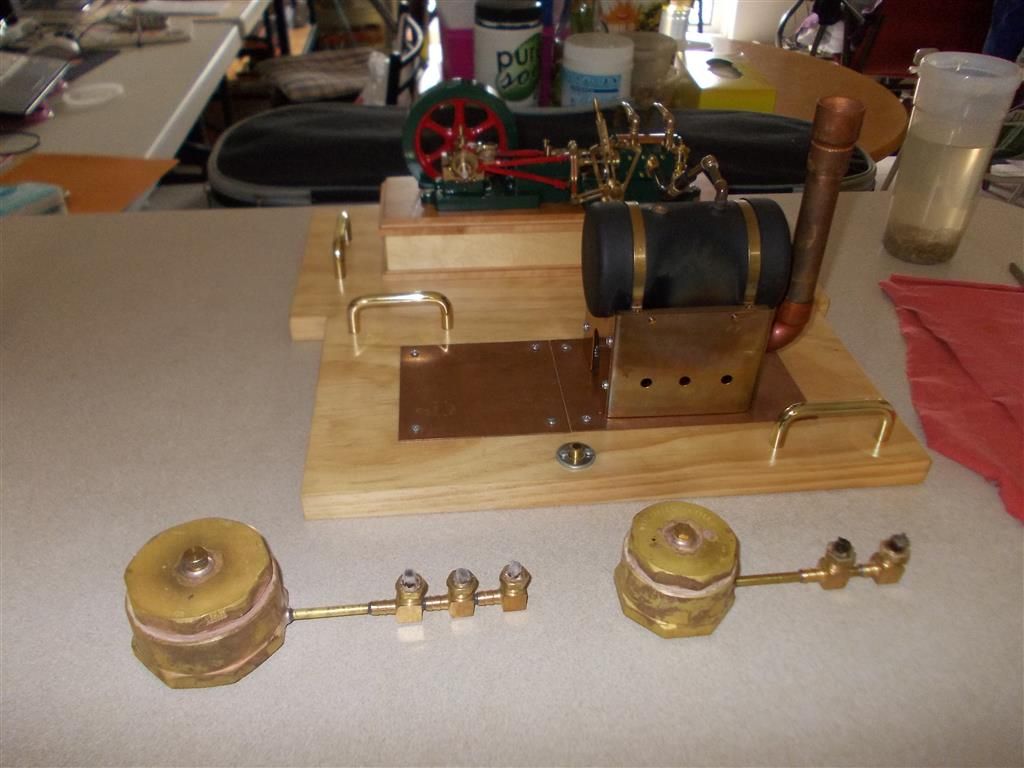

NEW STEAM TESTING : I have been running this engine on air for an hour per day for the last month. I suspect that this may have worn that Teflon seal down a bit so I tried to run it under steam today. The results were better but not outstanding. It did run at first but quickly ran out of puff. This happened with the MIDWEST wobbler engine so I then placed a piece of 1/8 tube inside the 3/16 steam outlet to restrict it. It worked with the Midwest engine but not with this one. I then installed a globe valve (not in the picture) in the steam line and opened it just a crack but with the same result. The engine runs for about one minute and then runs out of puff. I think I will need a stronger boiler to get this engine going for any length of time.

Quite strange as the PMR twin cylinder and single cylinder engines runs very fast for about 20 minutes with this boiler. But at least the Liegende engine was running on steam today so some progress has been made. I think I will still have to make proper pistons for the valve and main cylinder. I will also have to find some way to increase the heat to this boiler….gas perhaps ?

NOTE : the chimney came off the firebox towards the end of testing. I had used 243 degree soft solder so I was quite surprised. I did not expect that to melt. I will have to silver/hard solder it tomorrow but this could be tricky as the front plate of the firebox is only 0.6mm thick and could easily melt. A copper front plate may be required.

Edited By Brian John on 14/09/2015 08:03:14

Edited By Brian John on 14/09/2015 08:05:35

Brian John.