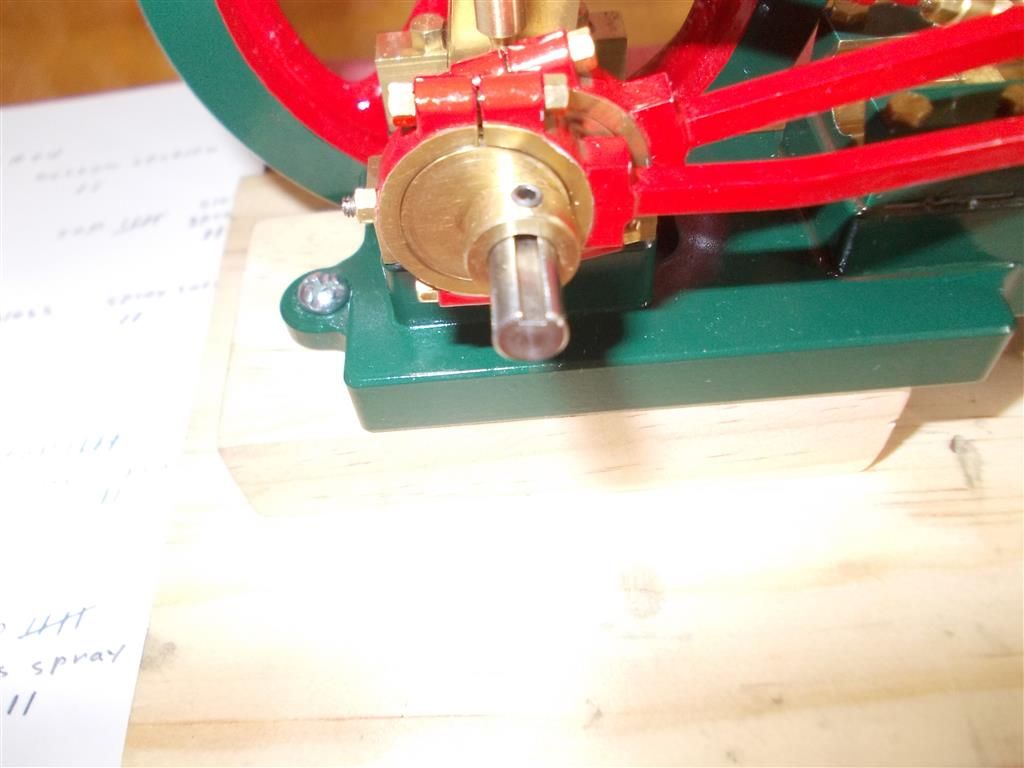

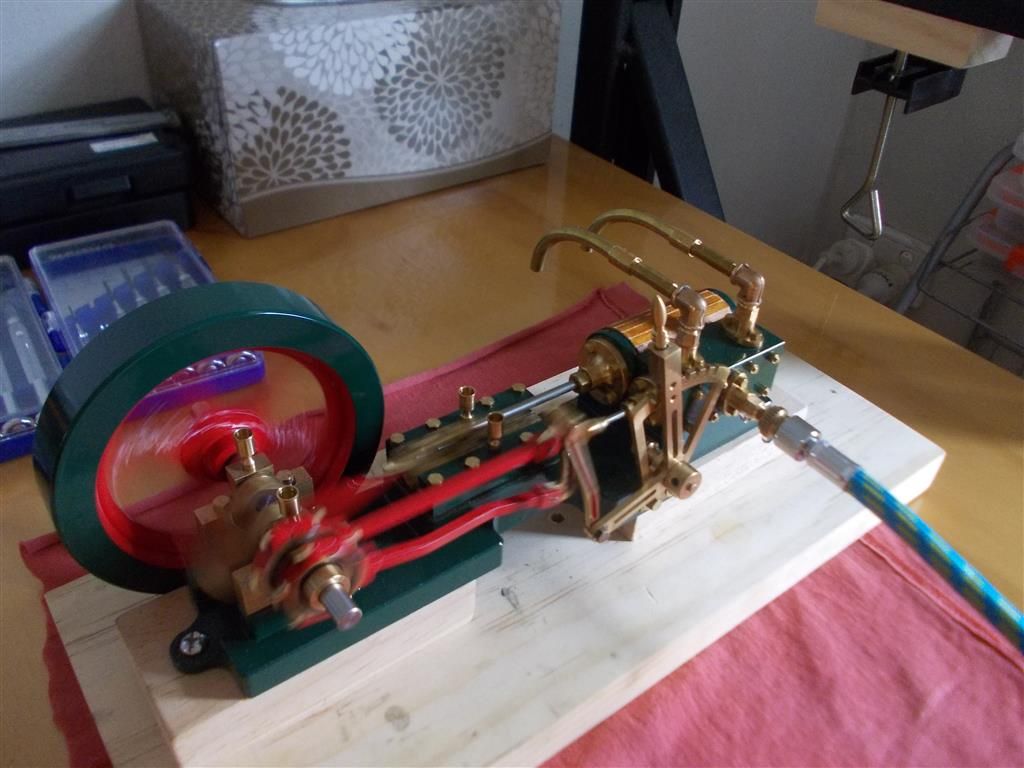

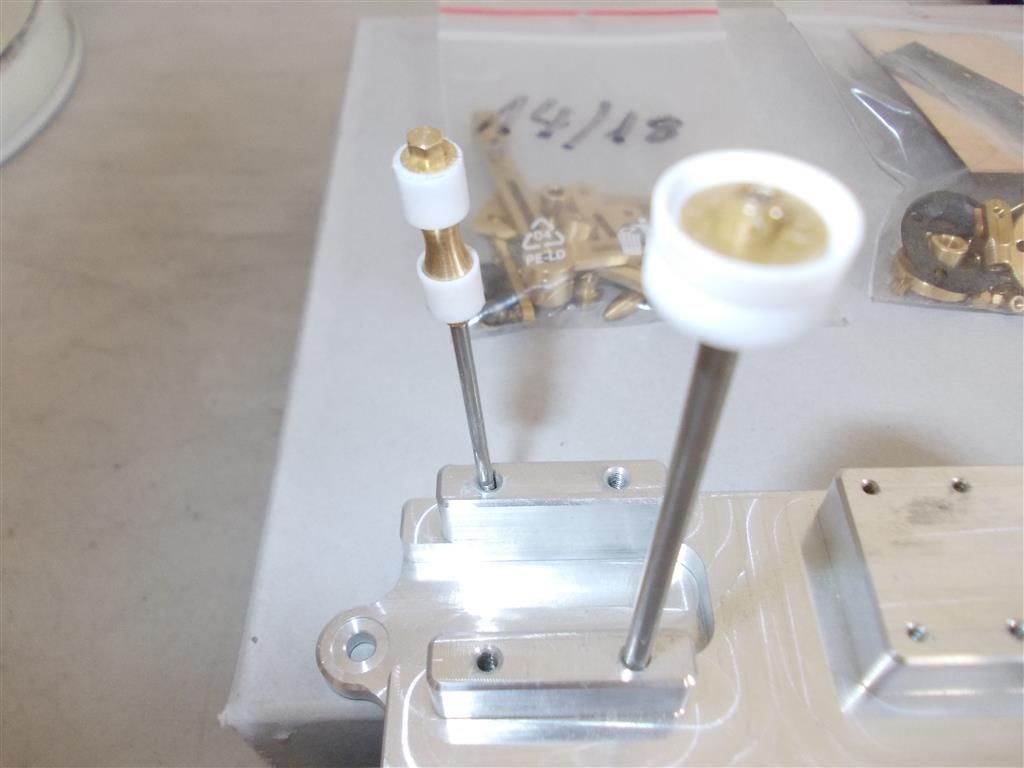

Update on steam testing : The first test produced a lot of water leaking from the packing nuts so I repacked them with TFE tape but the engine still refuses to run well on steam. As soon as water gets in the pistons then it locks up and it only has to be a tiny amount of water. As soon as I blow the air out by hooking up to a compressor then all is well again.

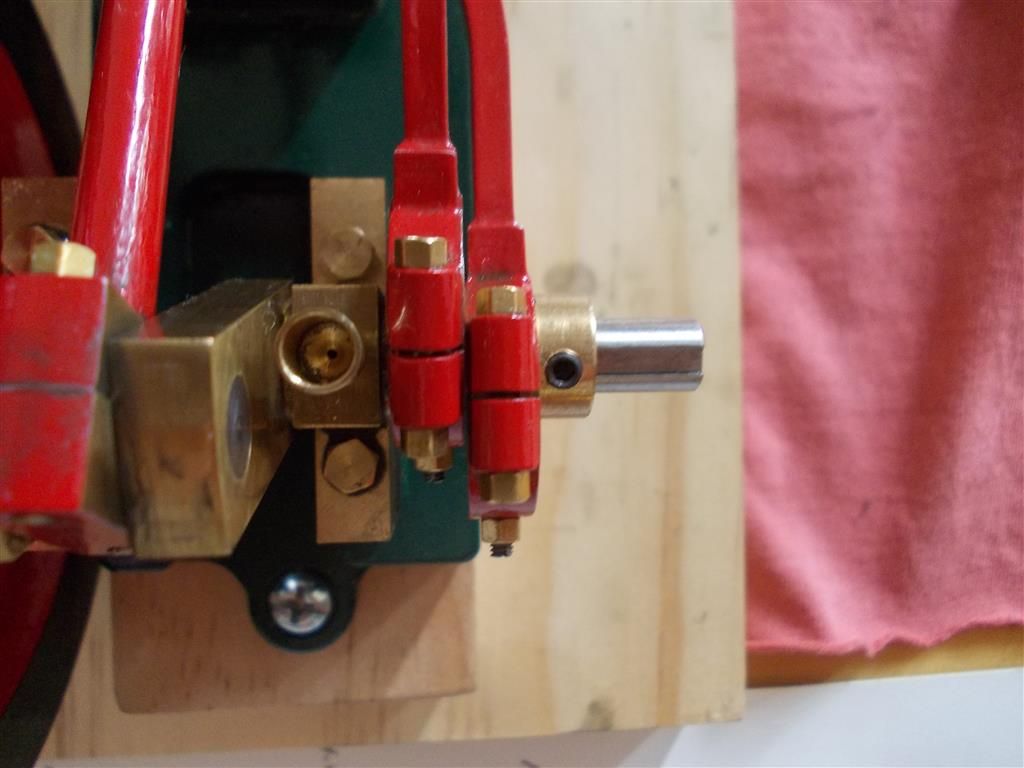

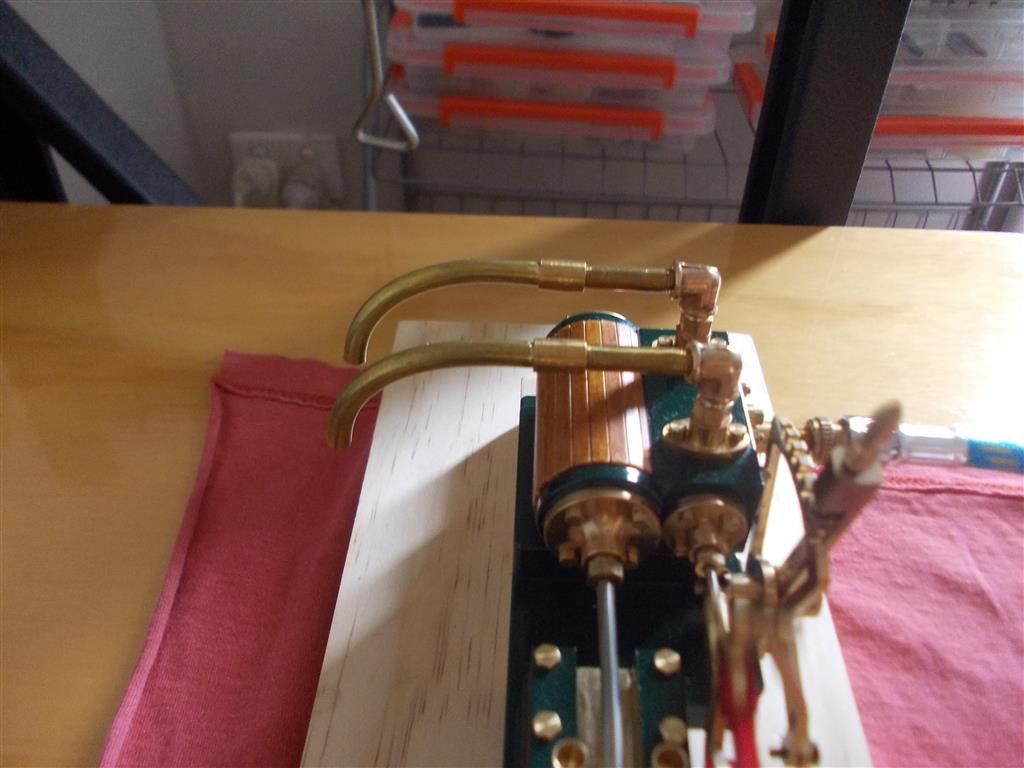

I have tried only half-filling my vertical boiler with water but that does not help. I have also raised the engine above the level of the boiler to see if that helps but it doesn't. That seemed to make it worse. I think my only options here are to either fit cylinder drain cocks but there is not much room on the cylinders :

http://www.ajreeves.com/cylinder-draincocks-316-x-40-4-6551-p.asp

or when my lathe arrives tomorrow to make proper pistons with piston rings as per the PM Research engines which do not have these problems.

Where would I buy or how would I make piston rings for small pistons like this ?

NOTE : the extra gland packing has made a huge difference to how this engine runs on air. Turn the compressor off and the engine seems to run on forever so that is some good news.

Edited By Brian John on 24/08/2015 07:45:08

Edited By Brian John on 24/08/2015 07:47:30

Edited By Brian John on 24/08/2015 07:52:12

Brian John.