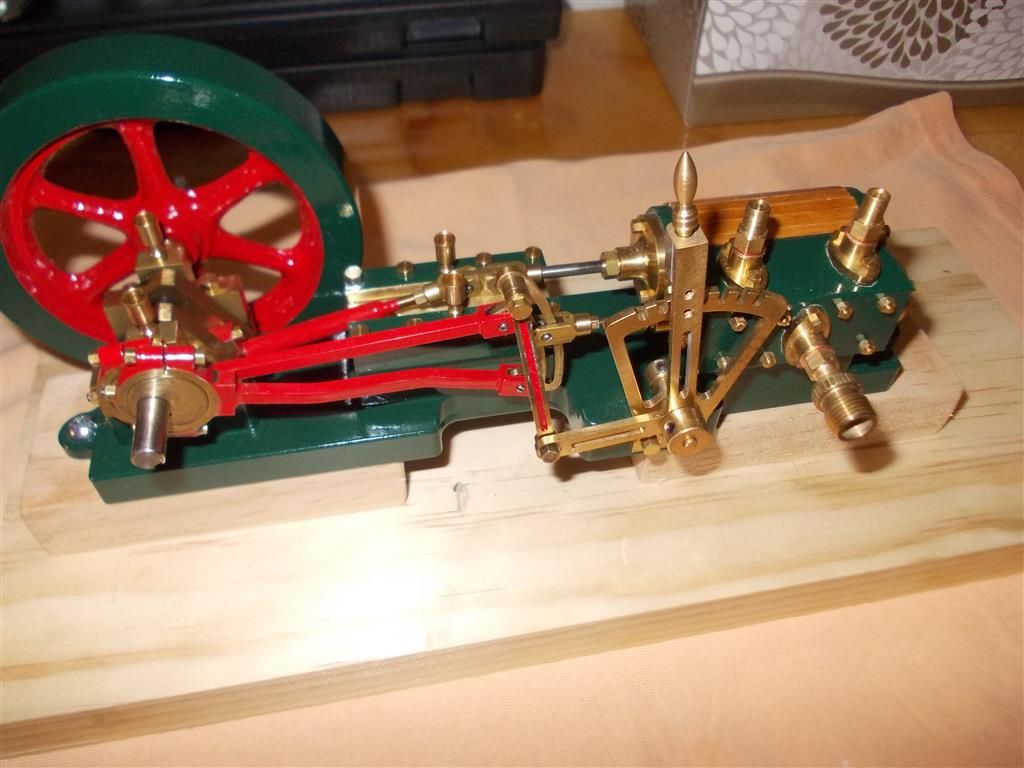

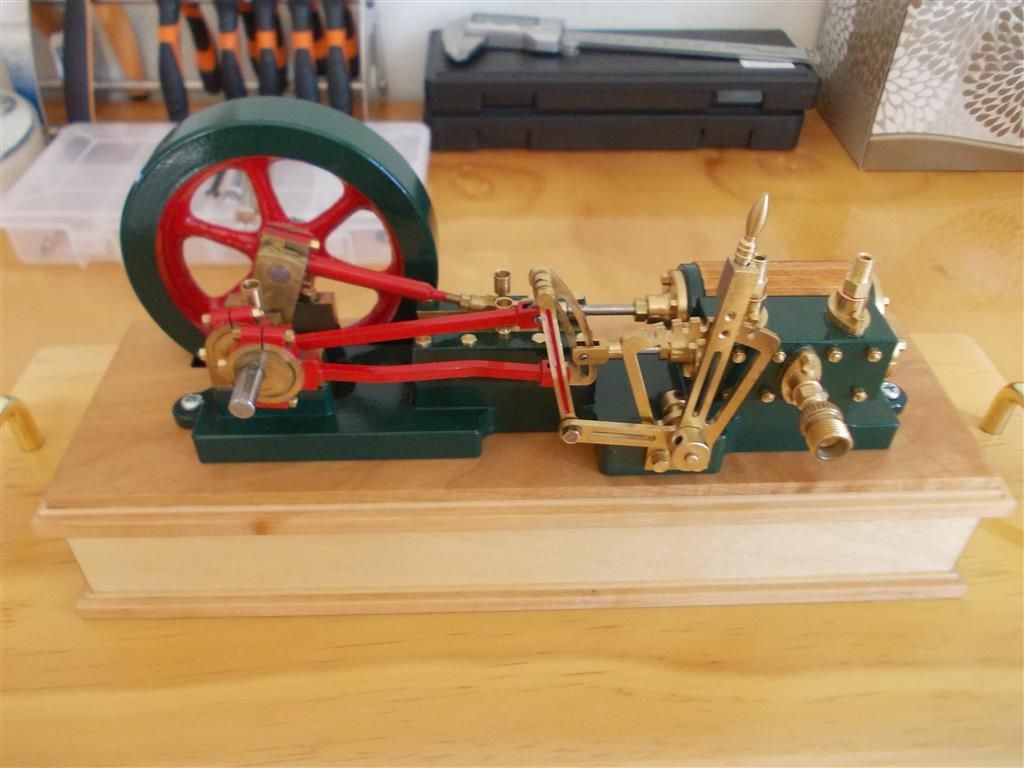

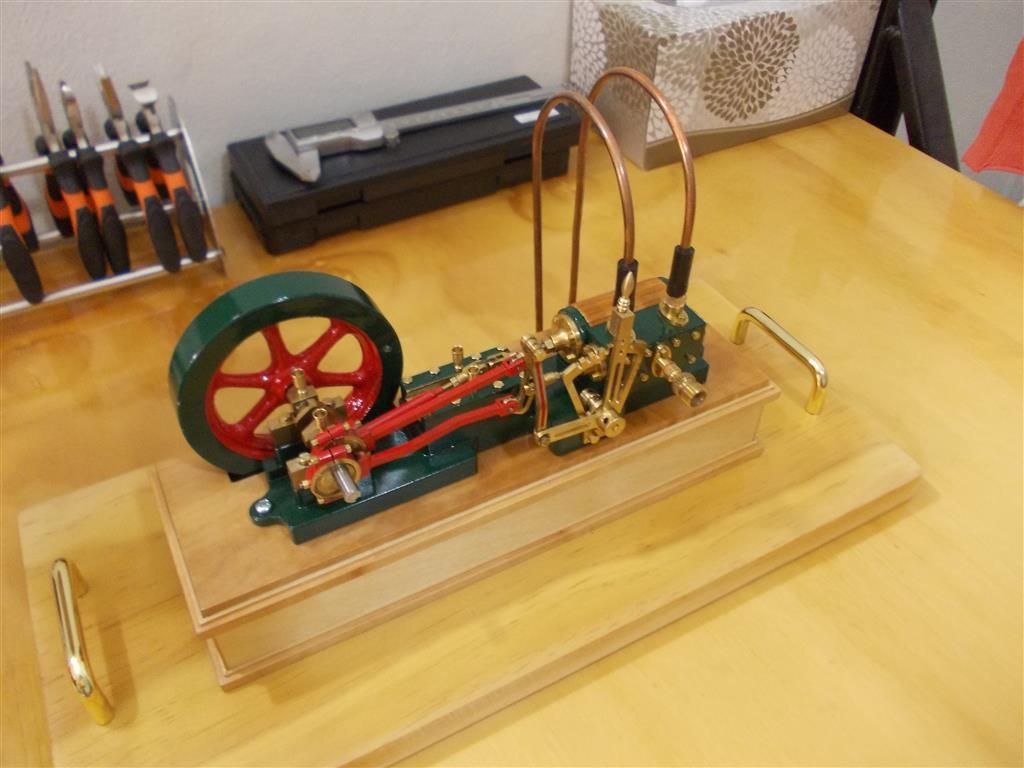

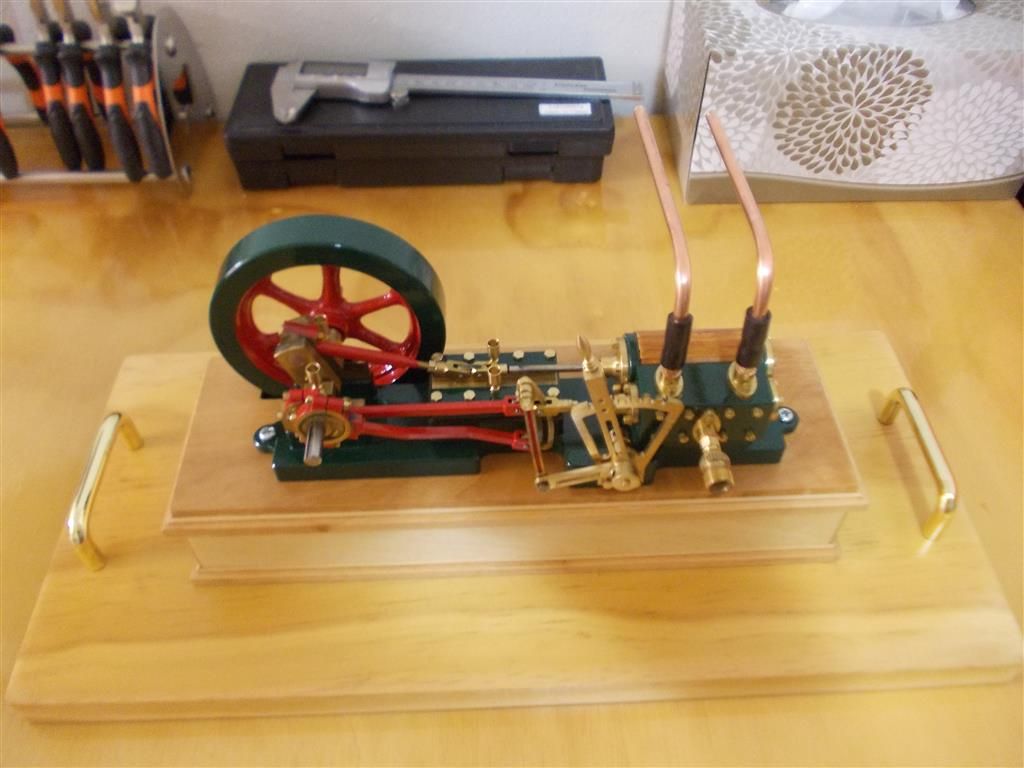

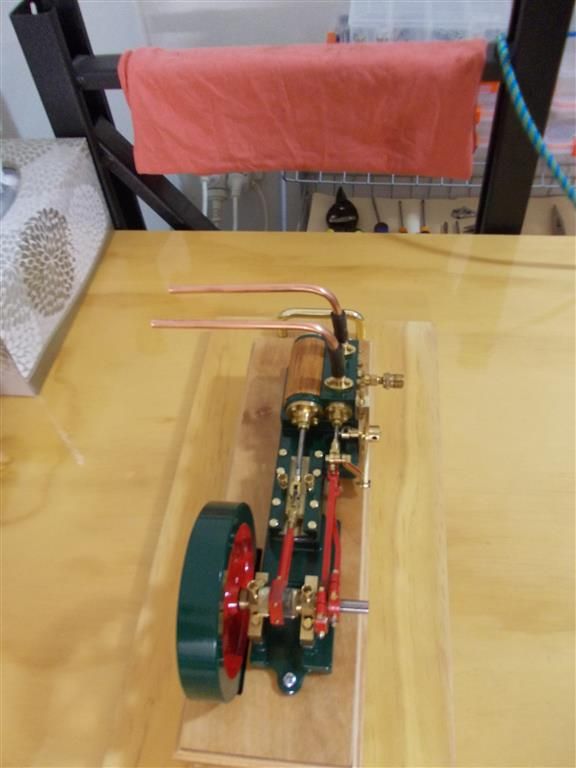

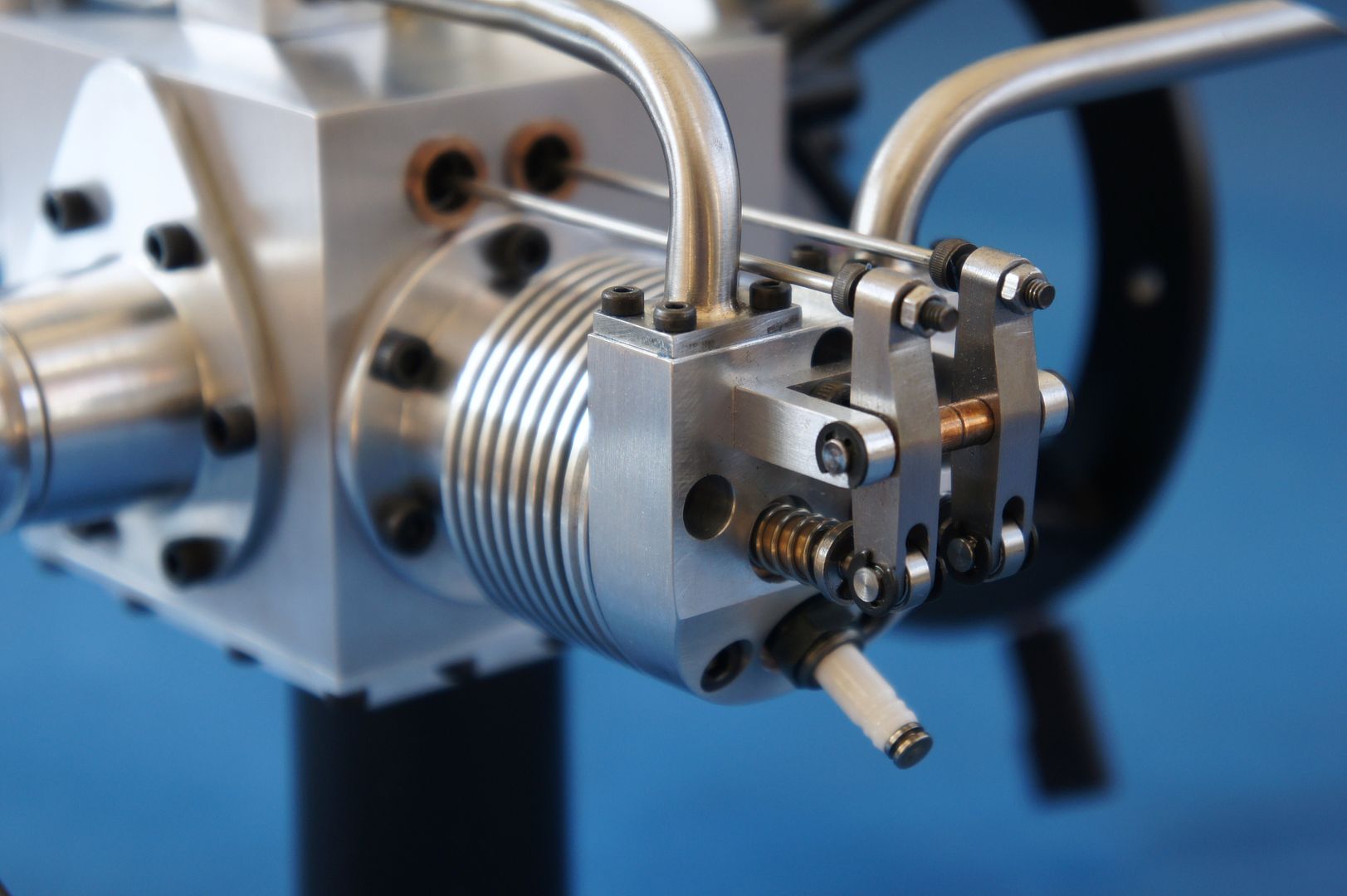

Well, the first steam test did not go well. This is my first engine with the exhausts on the top rather than the sides and as I suspected the water is not readily emitted and the engine ''chokes''. I will try again tomorrow : I will only half fill the boiler to eliminate any water getting into the engine. Unlike my other engines, this one does NOT like water in the cylinders as it jams up tight !

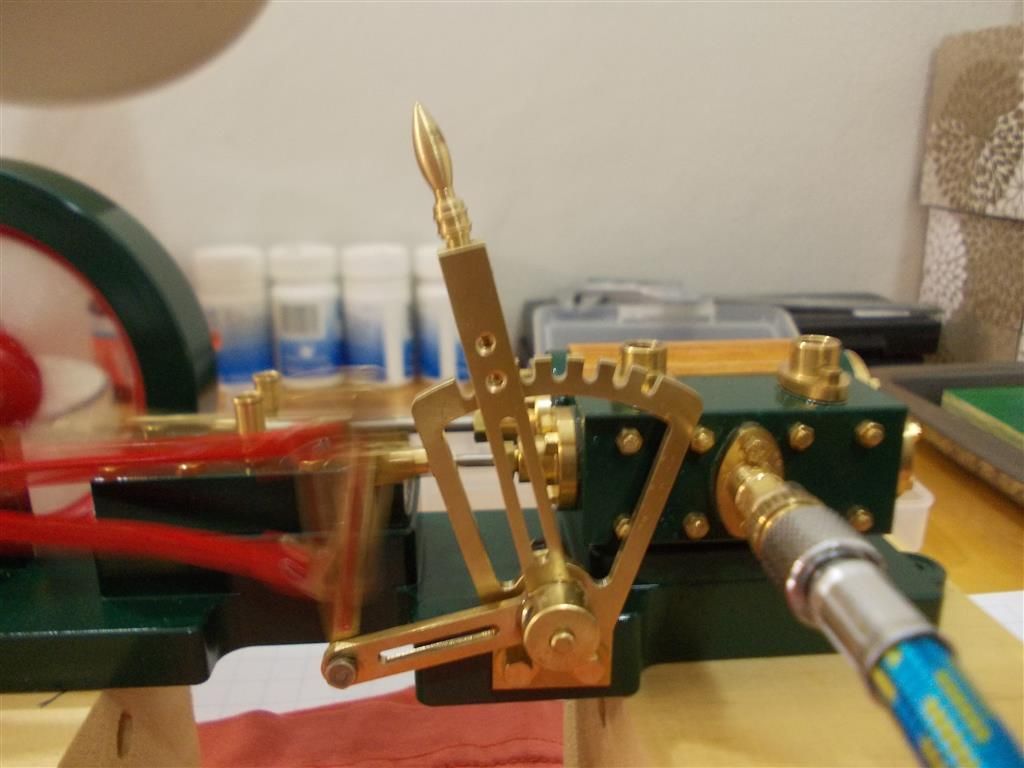

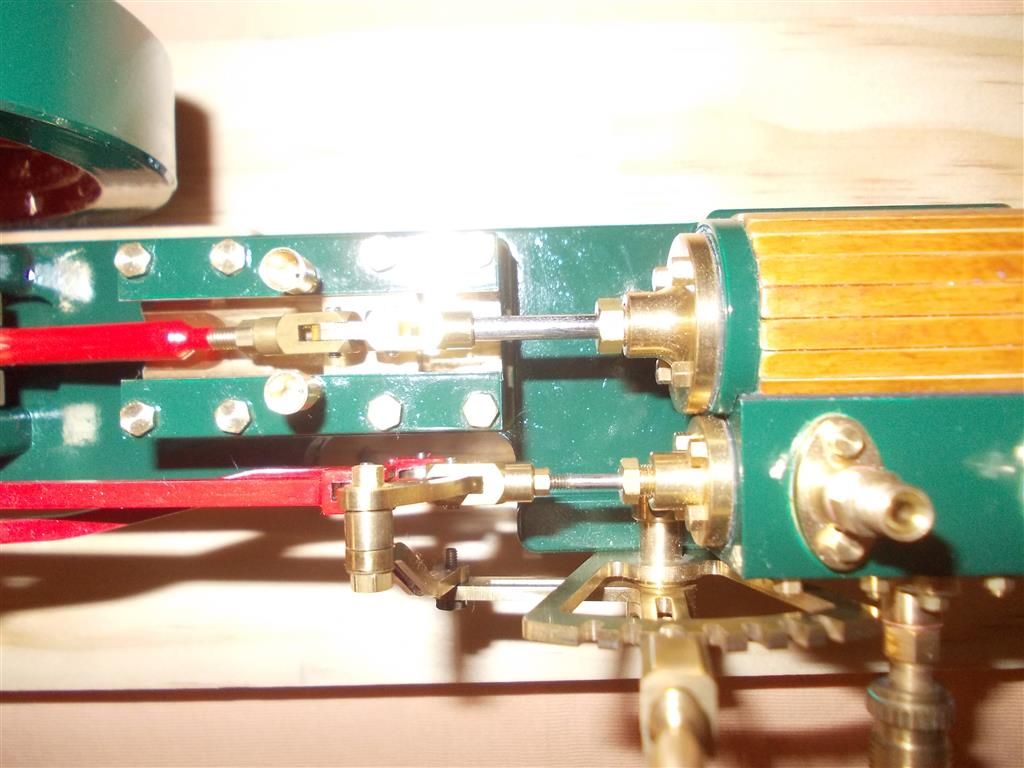

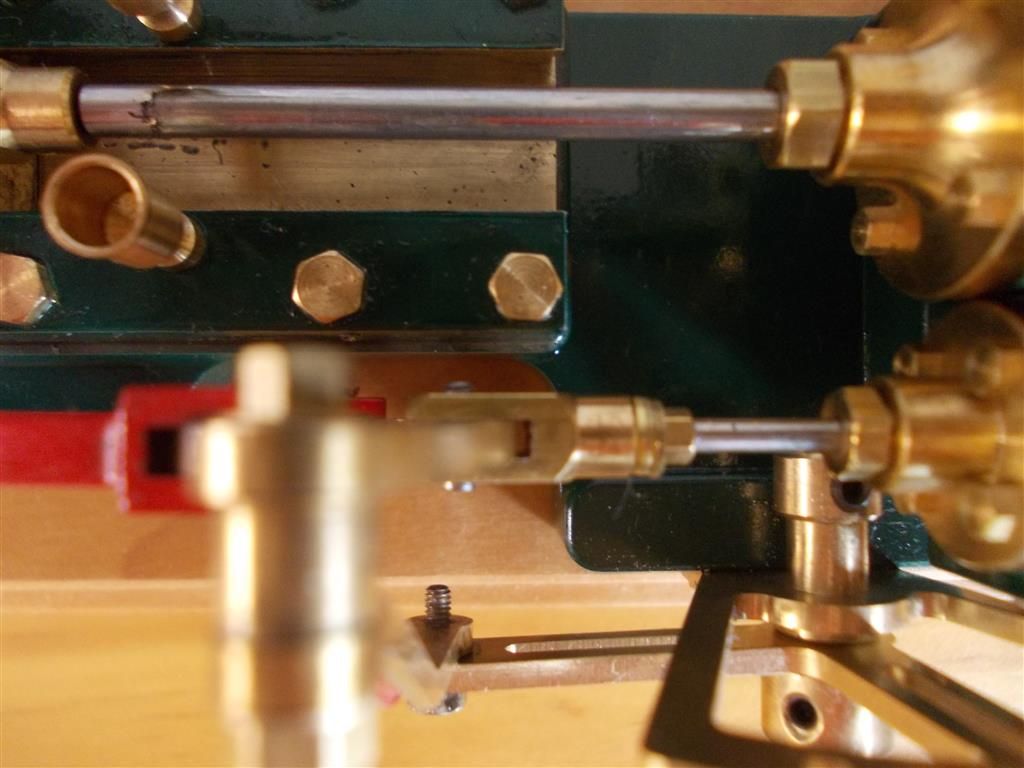

The lock nut on the control valve is still causing problems. It is time to try something different : I have moved the lock nut to the farthest point on the rod closest to the cylinder and used Loctite to hold this in place. It is now no longer a lock nut ; it is an adjustment nut. Hopefully I can now use this to adjust the length rather than having to remove the cylinder cover and adjust the valve using a nut driver. I know exactly where the valve should be set so I will put three 8BA washers between the nut (total of 1.6mm) and the clevis and then Loctite the rod into the clevis.

I suspect that the thread on the clevis is a bit oversize and this is why it is not holding. If I could get spare parts then I would order another but Regner in Germany never respond to my emails.

Edited By Brian John on 10/08/2015 08:13:00

Edited By Brian John on 10/08/2015 08:30:00

Brian John.