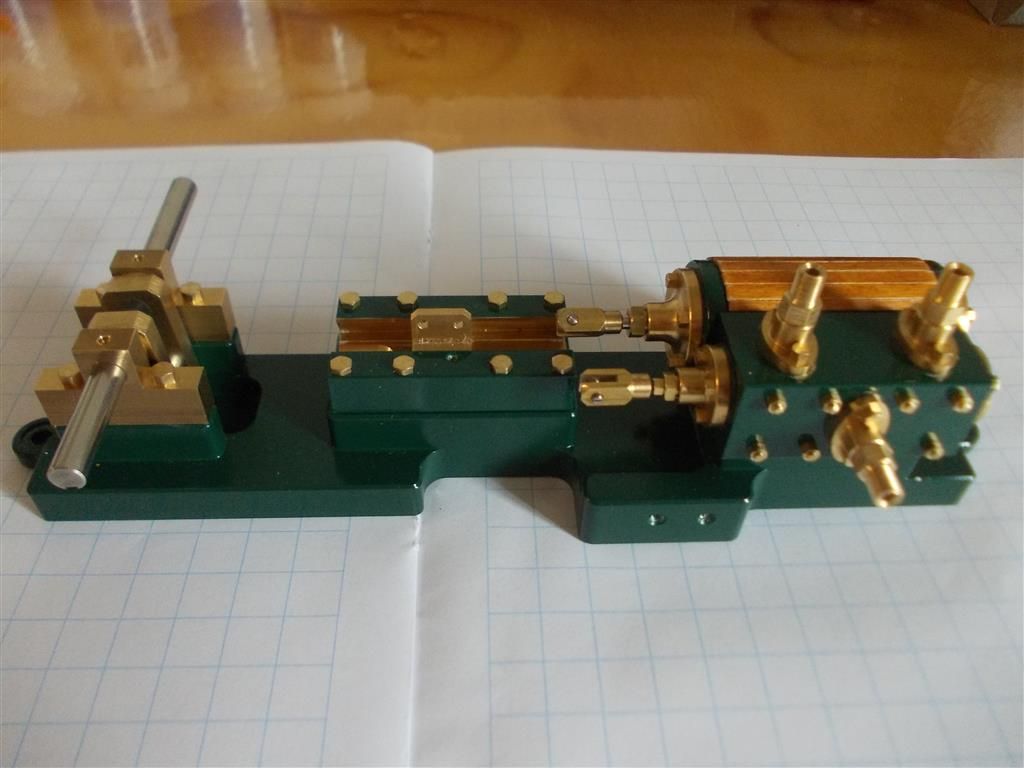

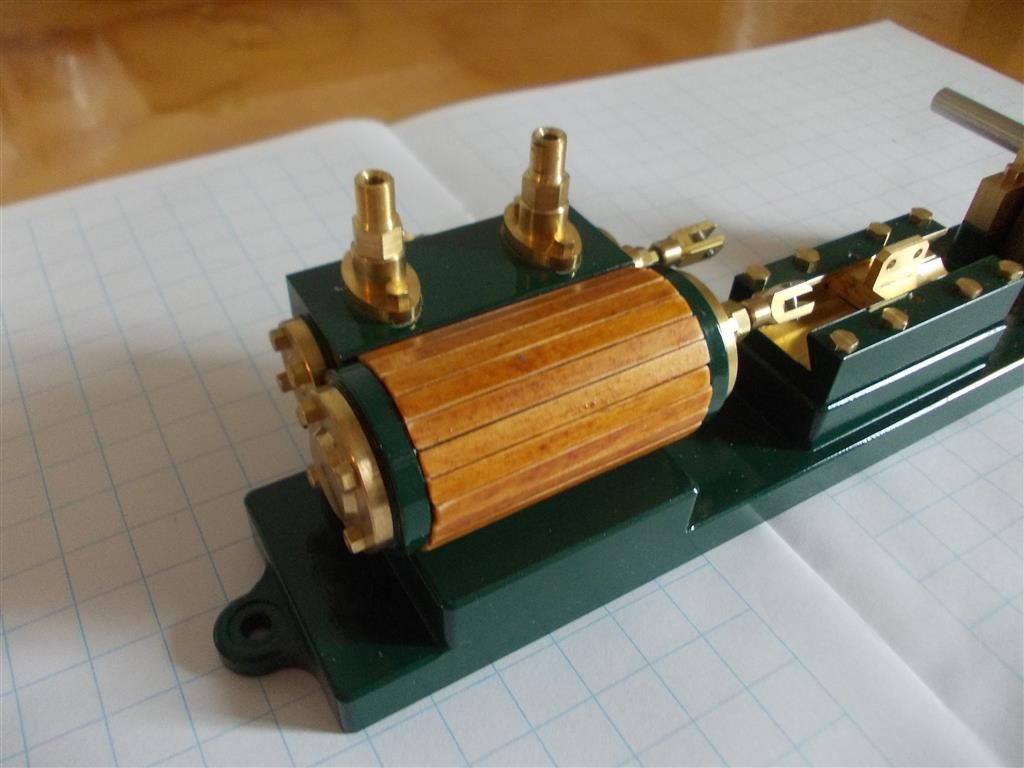

Has anybody built the steam engine kit : (40701) Liegende 12/36 ?

Has anybody built the steam engine kit : (40701) Liegende 12/36 ?

- This topic has 143 replies, 13 voices, and was last updated 3 August 2016 at 08:11 by

Brian John.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- DRO PCD function oddity?

- Diamond grinder wheels – Review

- Pipe Unions, Fittings, Standard Dimensions, CAD

- What size gear cutter for gear

- Schrader value core _extractor_ thread?

- Warco 220

- Myford 254S Lead screw lever issue

- Good quality Jewellers screwdrivers.

- 24cc DIESEL ENGINE FROM SOLID

- Measuring increments on boring head