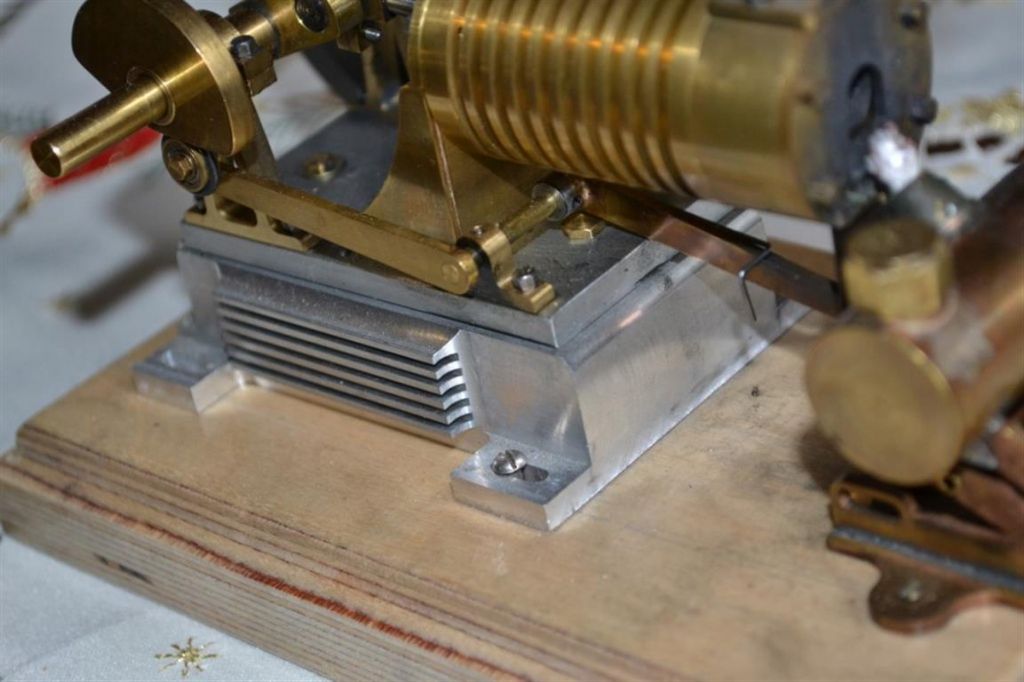

Leaving flywheels aside for today, I commenced work on the cylinder assembly. The cylinder head was attached to the cylinder with a large bolt (as per Jason's link) and then the four holes drilled out to 1.6mm using plenty of tap magic. The cylinder head was then removed and the four holes tapped for M2, again lots of tap magic.

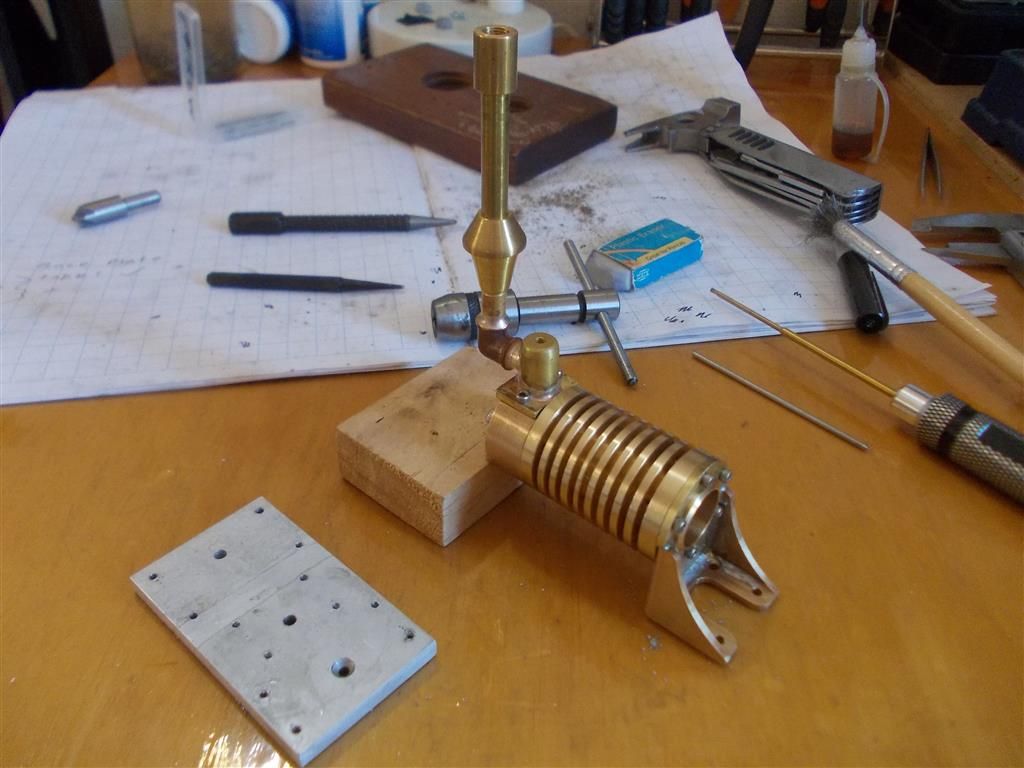

The cylinder bracket was fitted and the top hole carefully marked, punched, drilled and tapped for M2. I previously went to a lot of trouble to get my chimney assembly straight so I did not want to muck it all up by getting the cylinder bracket off centre. Once that top centre hole was tapped I could screw the bracket in position then drill and tap for the other holes. All went well and my chimney is nice and straight.

At this point I realised that I have not drilled and tapped for the lubricator and I think I should have done that before boring the cylinder. I also need to work out a way to support the cylinder head as I am not happy with the initial design which has everything supported only by the cylinder bracket. It all looks a bit flimsy to me. I have a few ideas in my head but suggestions are welcome.

NOTE : I have measured my small drill bits and they seem to be slightly oversize. The 1.7mm are actually 1.75mm and the 1.6mm are 1.65mm. So I am going back to using a 1.6mm tap drill for M2 screws but now I use tap magic for each tap (first , second and third). Hopefully this will be enough to prevent any further broken taps. I now use tap magic when doing anything involving M2 screws and that includes drilling.

Edited By Brian John on 08/06/2016 11:51:19

Edited By Brian John on 08/06/2016 12:02:09

Edited By Brian John on 08/06/2016 12:03:39

Brian John.

Depending on the situation you ought to have the choice of making your own axle, or turning down the end, press fitting a new chunk on there and turning it to fit or even boring a larger hole into the flywheel and fitting a new centre and try again.

Depending on the situation you ought to have the choice of making your own axle, or turning down the end, press fitting a new chunk on there and turning it to fit or even boring a larger hole into the flywheel and fitting a new centre and try again.