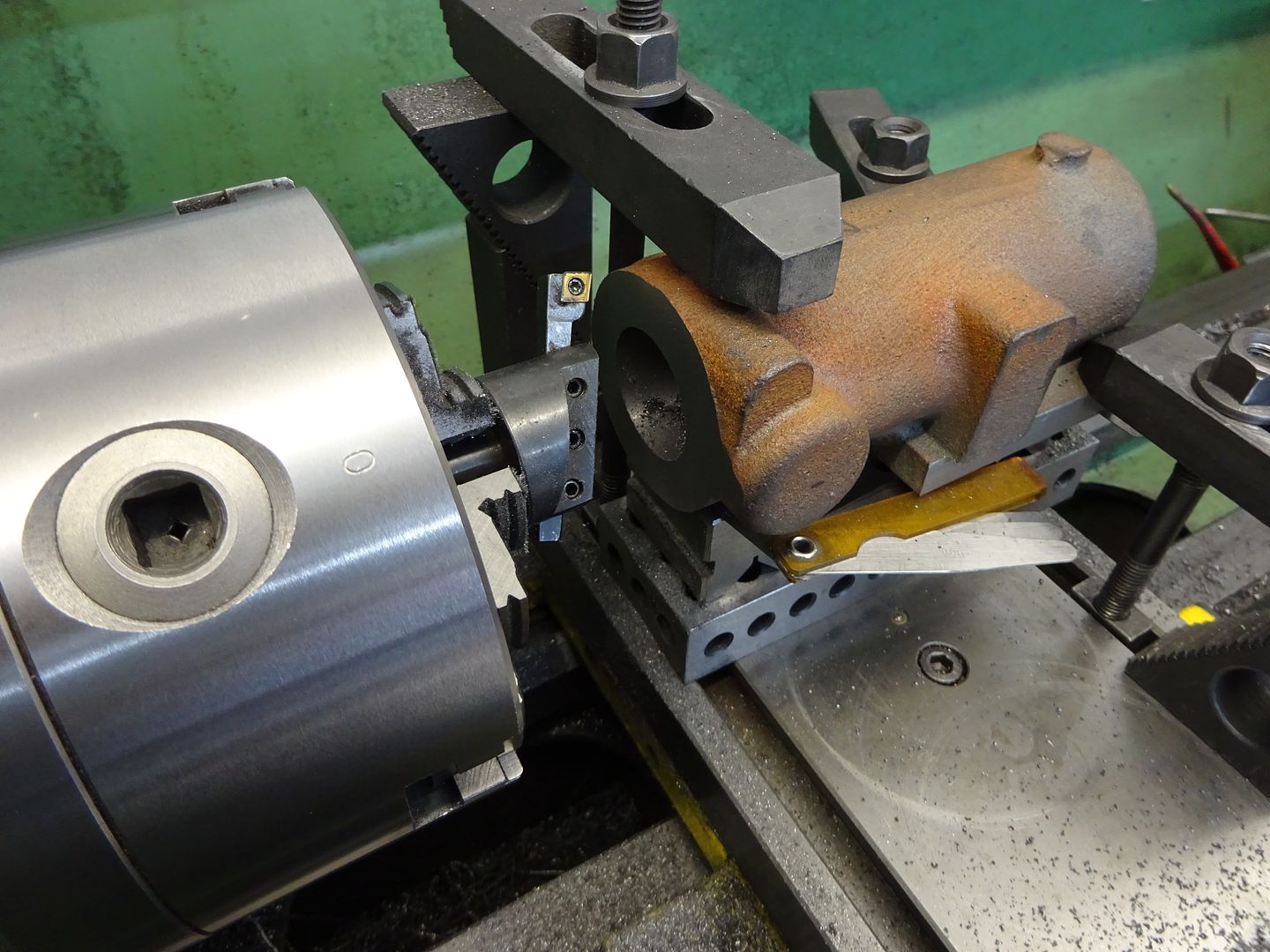

I had a few problems making up the cylinder head (part 21) today. I marked an 18mm chord on the work piece then attempted to cut it off with the slitting saw. I wasn't sure if the piece could be held firmly with only one bolt but it was no problem. The slitting saw would only cut half way before the nut got in the way even though I was using a smaller nut than that supplied with the saw. So I had to turn it over to complete the cut. The cuts did not meet so I evened things up with the bench grinder then I used a large file while the piece was held in a vice. By the time I got a perfect rectangle on top I was down too far and the chord was actually 21mm.

So I fished around in my box of parts and found two 30mm diameter brass cylinders which were 12.5mm thick, both with a 6mm hole already drilled…sometimes you get lucky ! I faced off until they were both the required 12mm thick and bored out the centre holes to 8mm. I used the slitting saw to cut a 15mm chord (not 18mm), then the bench grinder, then the big file while held in the vice and finished off with 800 grit on a sheet of glass. This time I ended up with the correct dimensions and a perfectly flat surface on which to mount the exhaust chimney. Yes, I made two of them ! I still have to tap and drill them tomorrow ; extra care needed here.

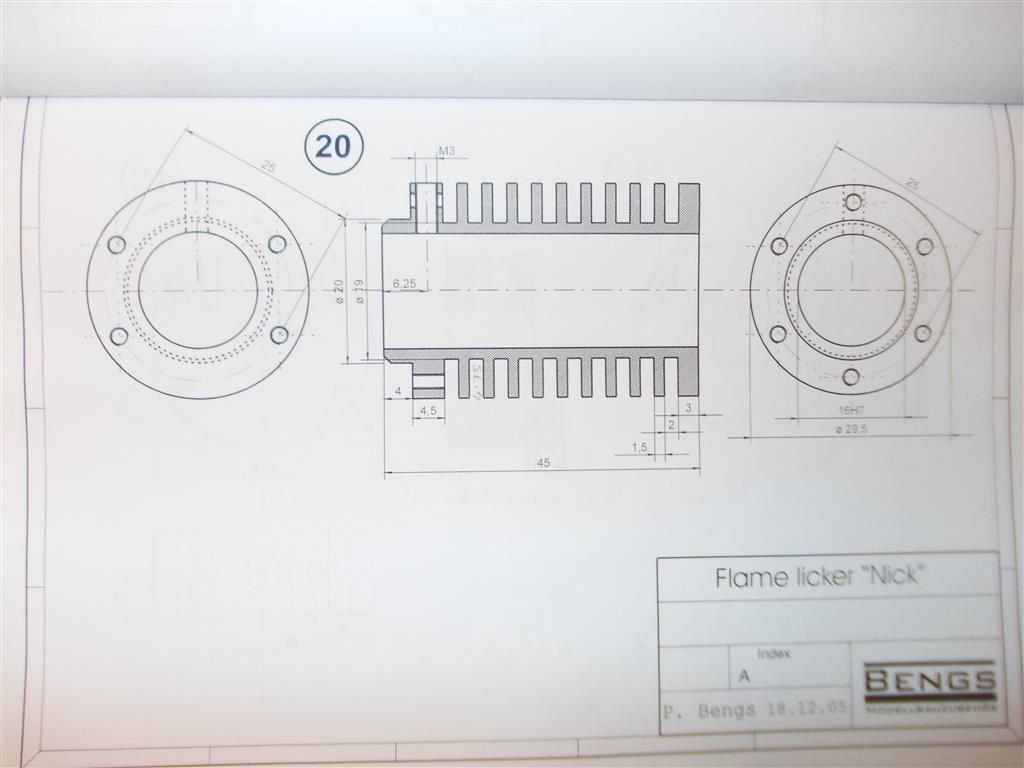

If you look at the plans above you will see that they mark the countersunk hole as 7X90 degrees. Where do they get 90 degrees from ? All the countersunk holes are marked like that.

Edited By Brian John on 30/05/2016 10:22:30

Edited By Brian John on 30/05/2016 10:23:04

Edited By Brian John on 30/05/2016 10:24:03

Edited By Brian John on 30/05/2016 10:25:23

Brian John.