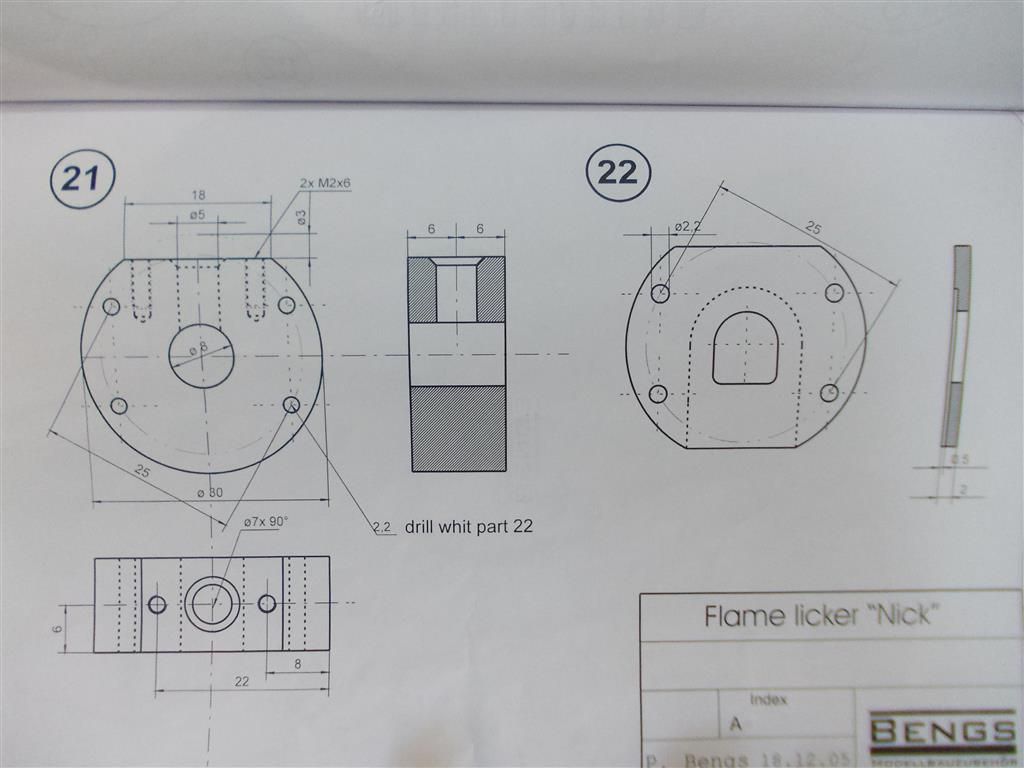

Has anybody built the flame eater “Nick”?

Has anybody built the flame eater “Nick”?

- This topic has 245 replies, 19 voices, and was last updated 8 October 2017 at 03:37 by

Brian John.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Supply company catalogues

- Damp proofing concrete floors

- Machinery Handbook

- Chester DB10LB Lathe – Not starting

- Measuring increments on boring head

- Elliott Omnimill Quill Clamp

- Problem getting the right parameters on a VFD

- Flattening brass plates

- How to wire up 3 phase motor and 3 phase converter?

- Morse Key