Good to know you are enjoying them.

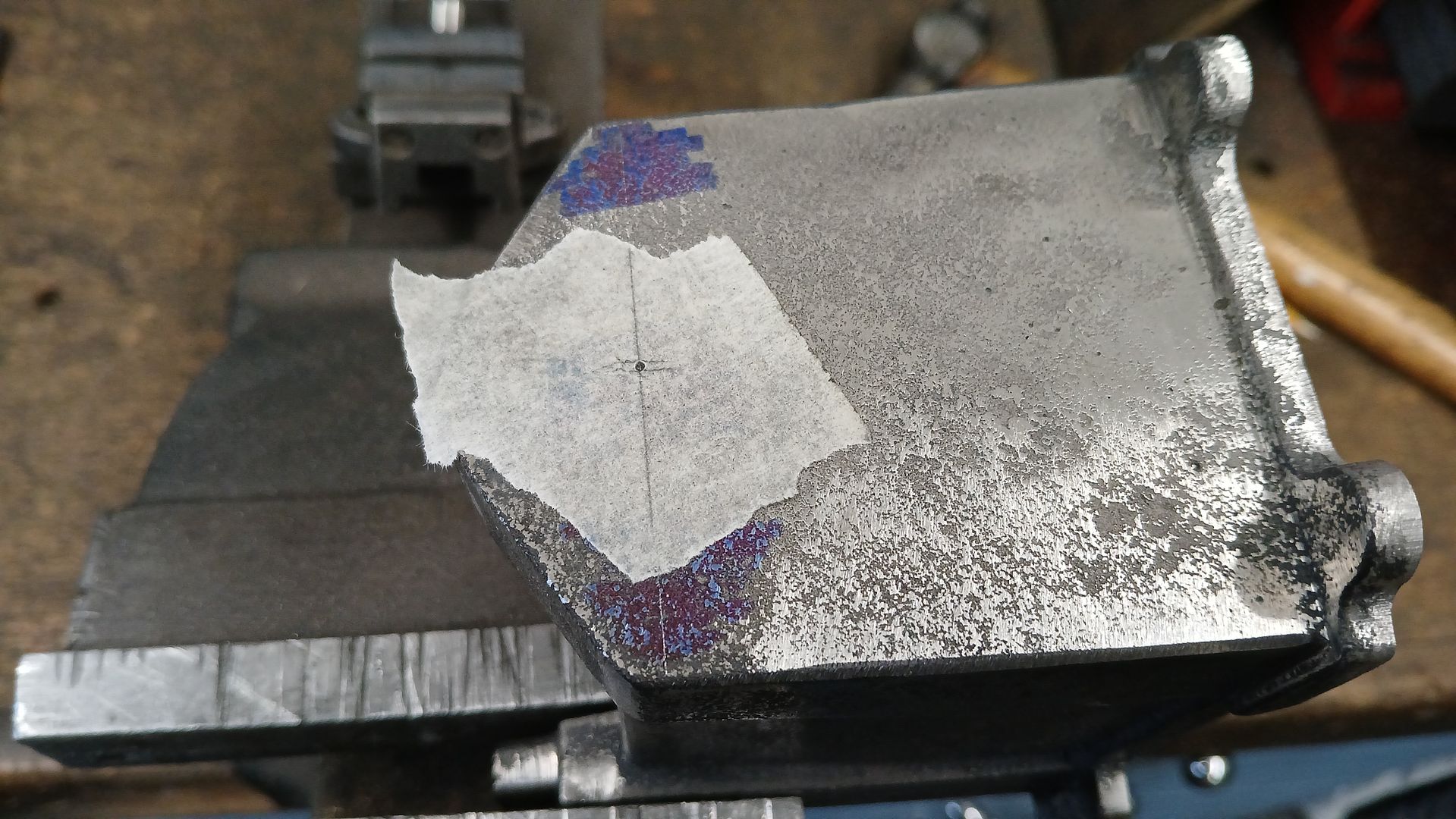

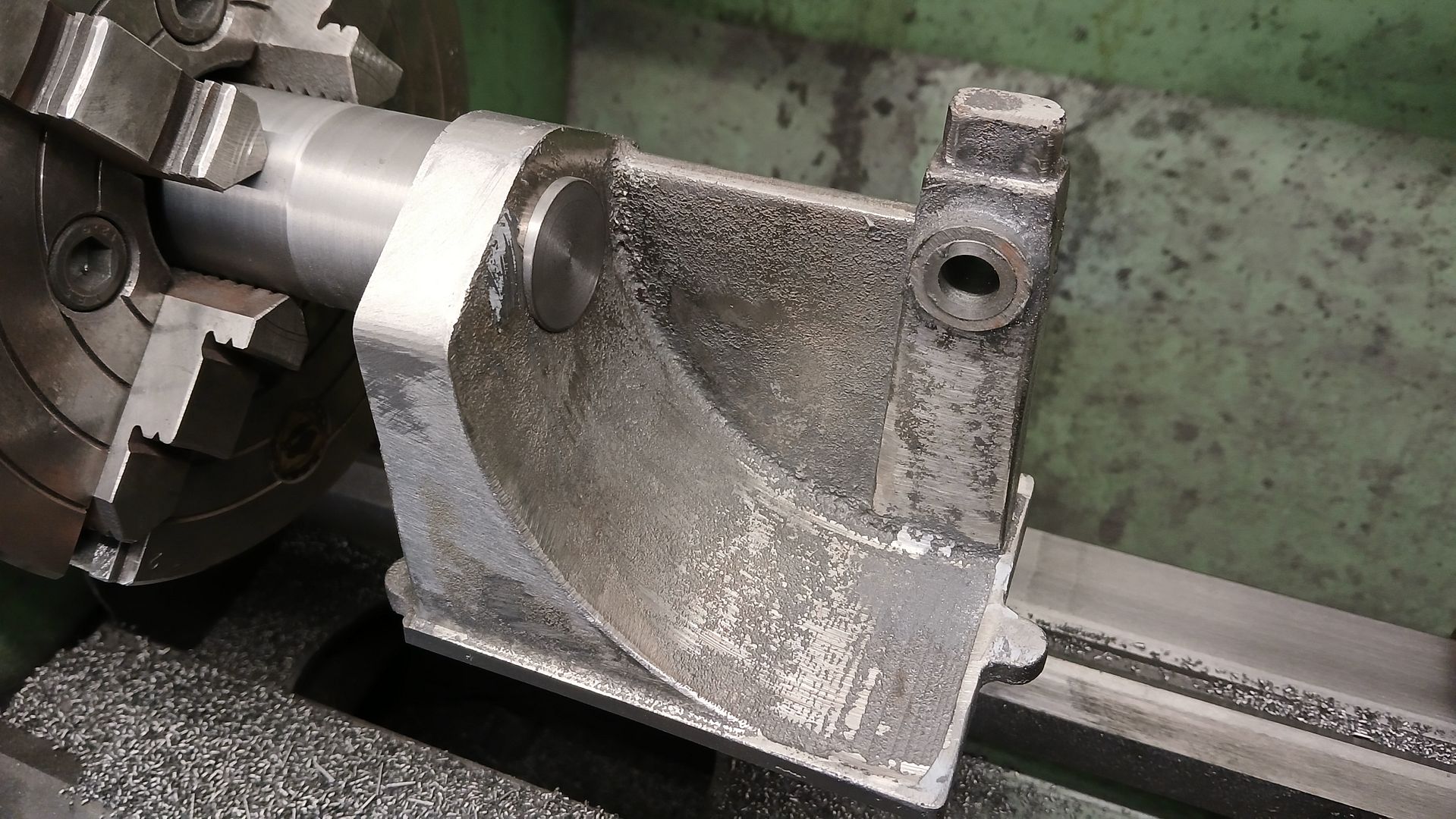

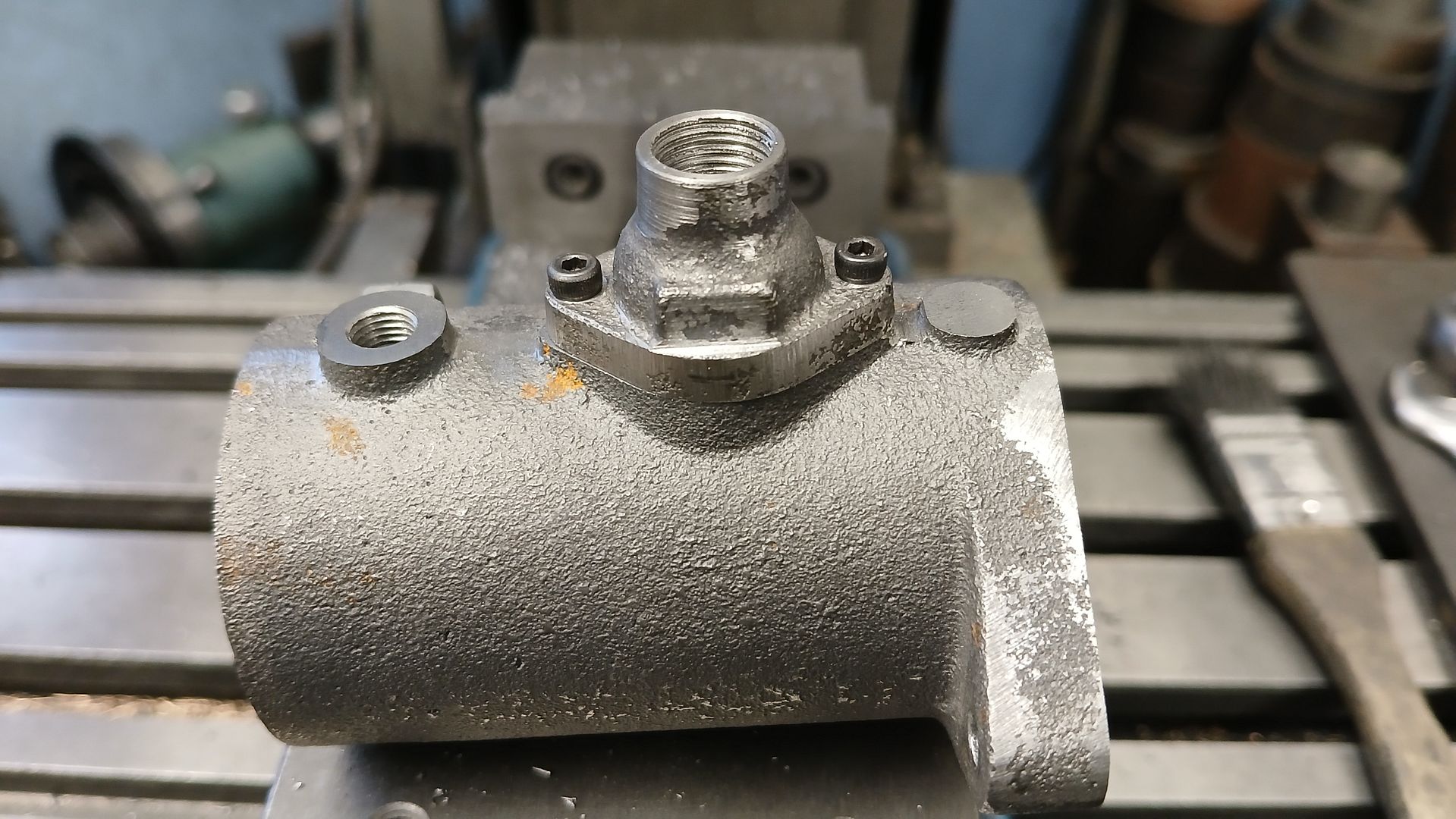

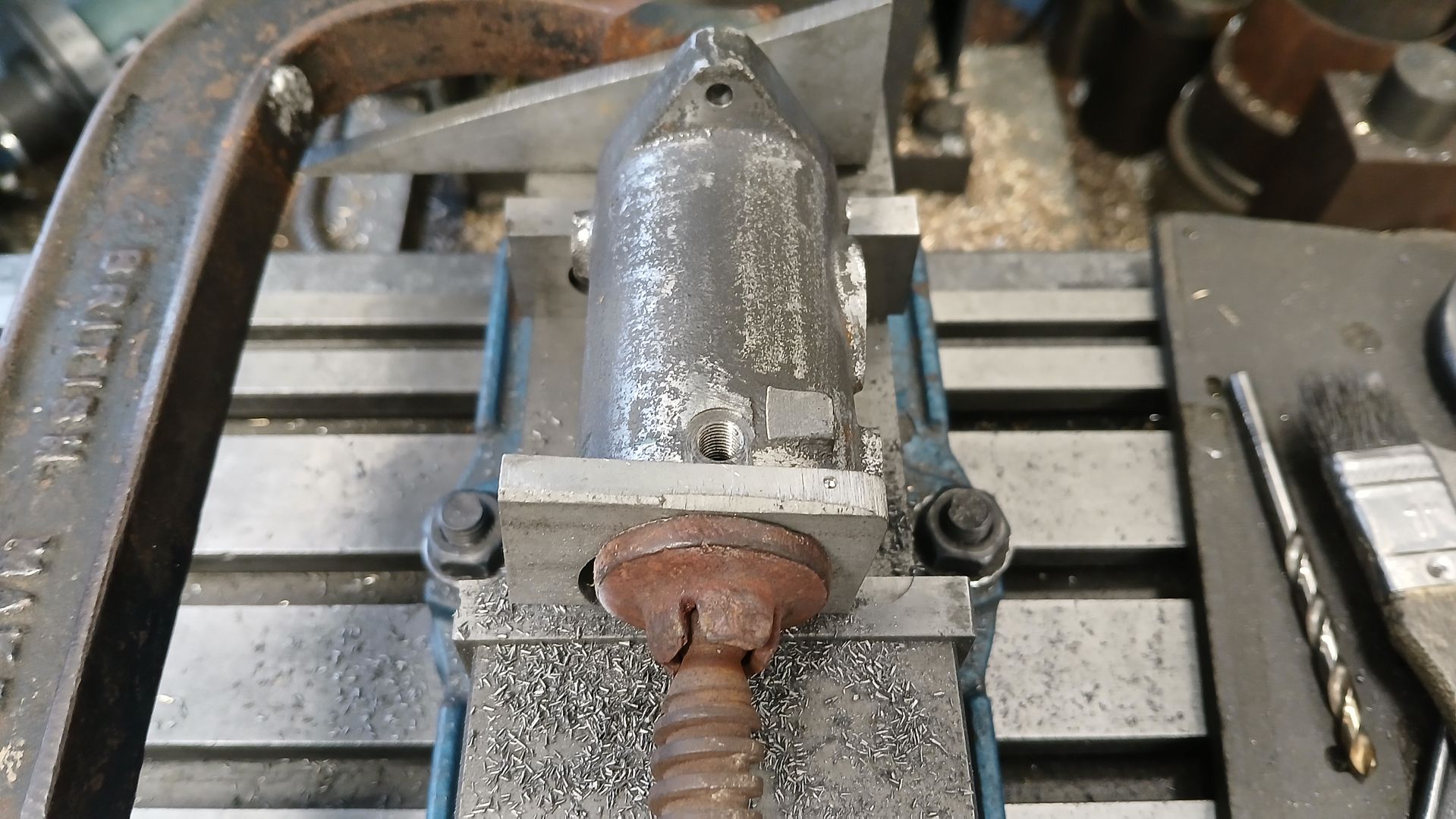

The only other thing I have done to the base is to machine the other side of the crankshaft housing back to 19mm from the engine ctr line and then tidied up the JBWeld fillet. I tend to leave the excess filler/adhesive in place until after machining as it probably makes for a slightly more supported joint.

My cylinder came out really well with a good finish and no signs of layer lines from the pattern. We decided not to core this as it is quite a small casting and the cost of the extra material is minimal.

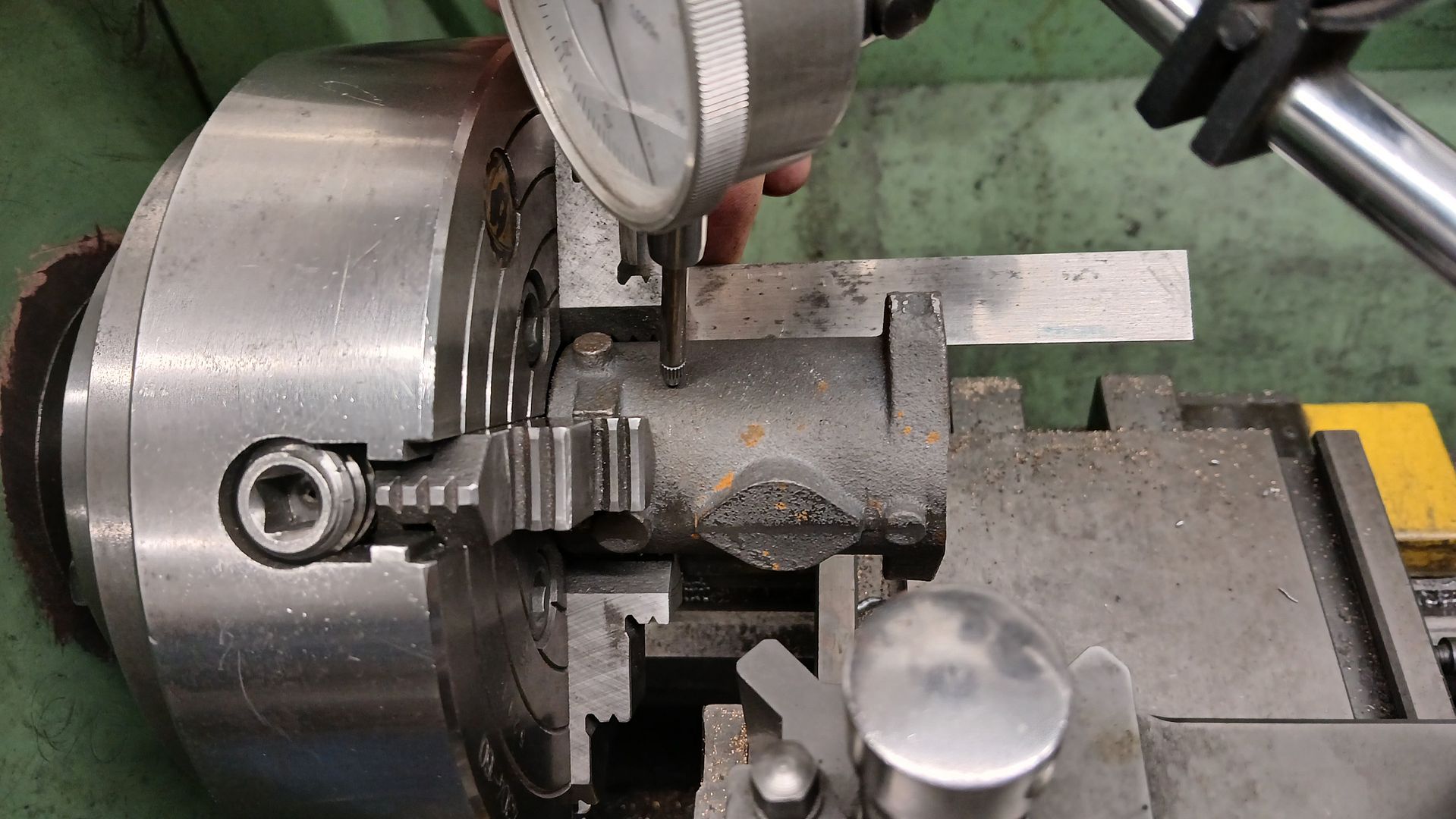

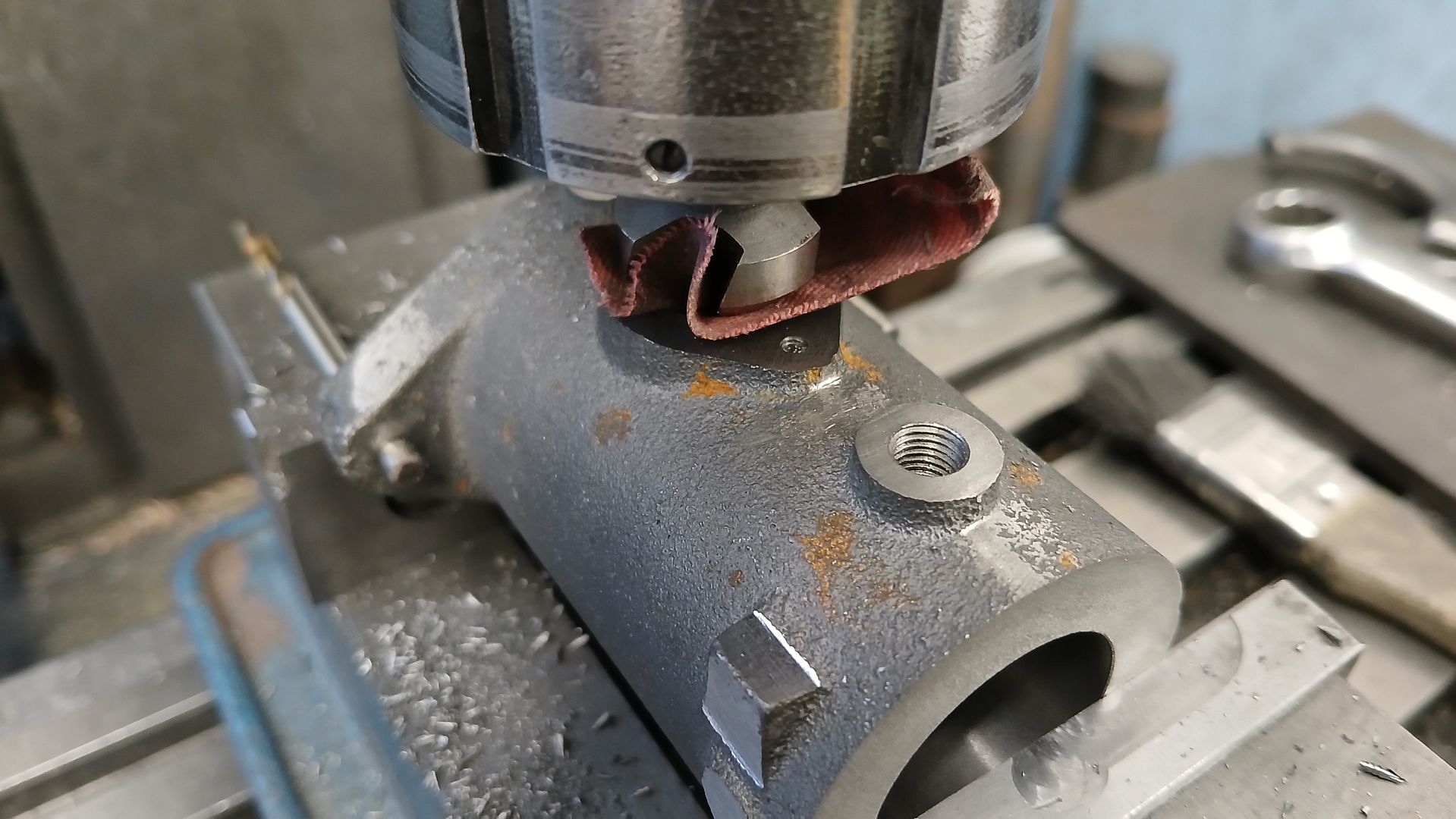

I set it up in the 4 jaw getting the head end as true as you can with a cast surface, the dti was used to get North & South and East & West even together with a square to make sure things were as true as possible.

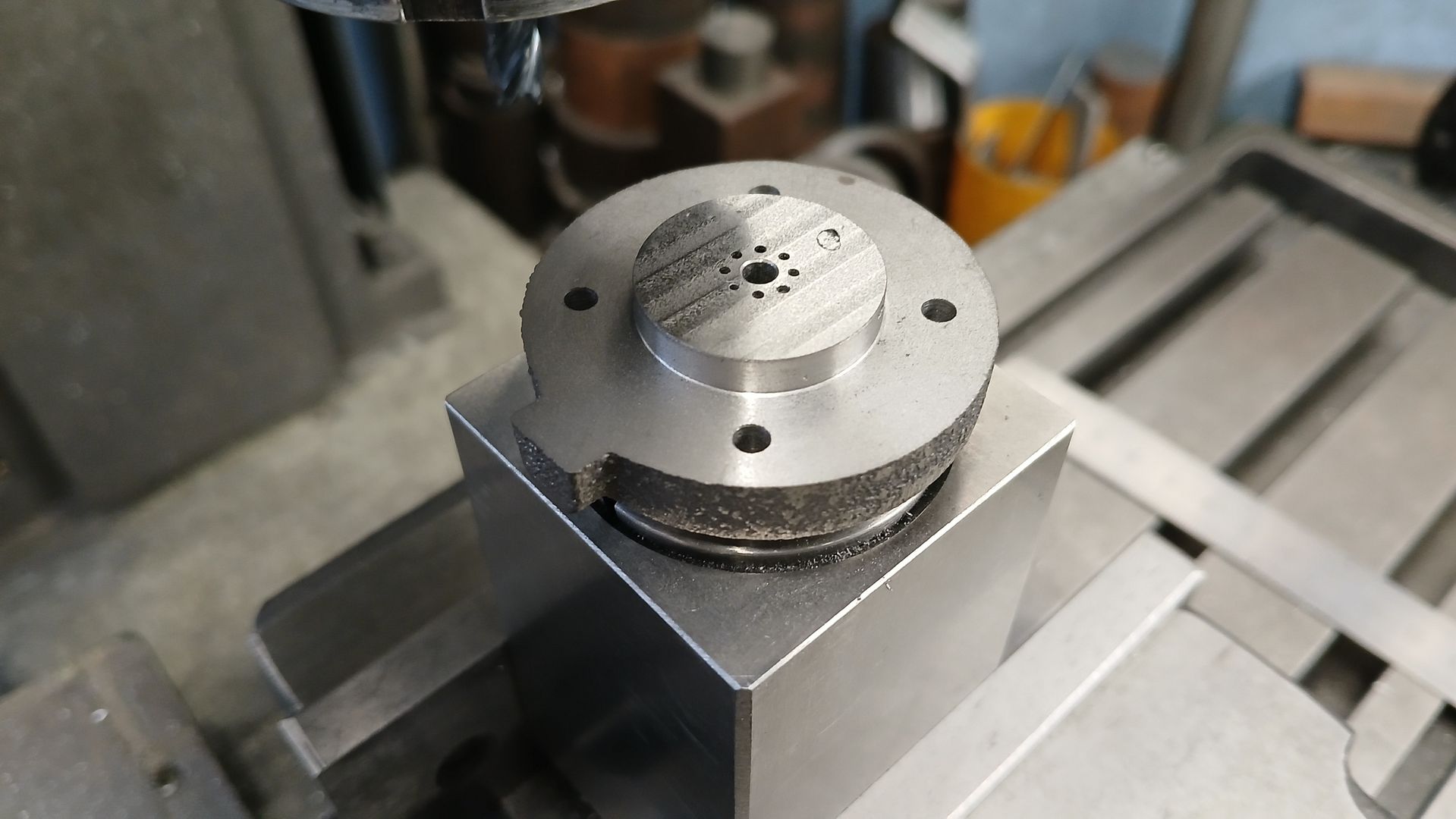

The flange was then faced back to leave it the correct distance from the middle of the first cast boss and then it was bored. There are three diameters. 26mm at the head end, 33mm for the water space and 35mm for a small lip on the liner to locate it’s position length ways.

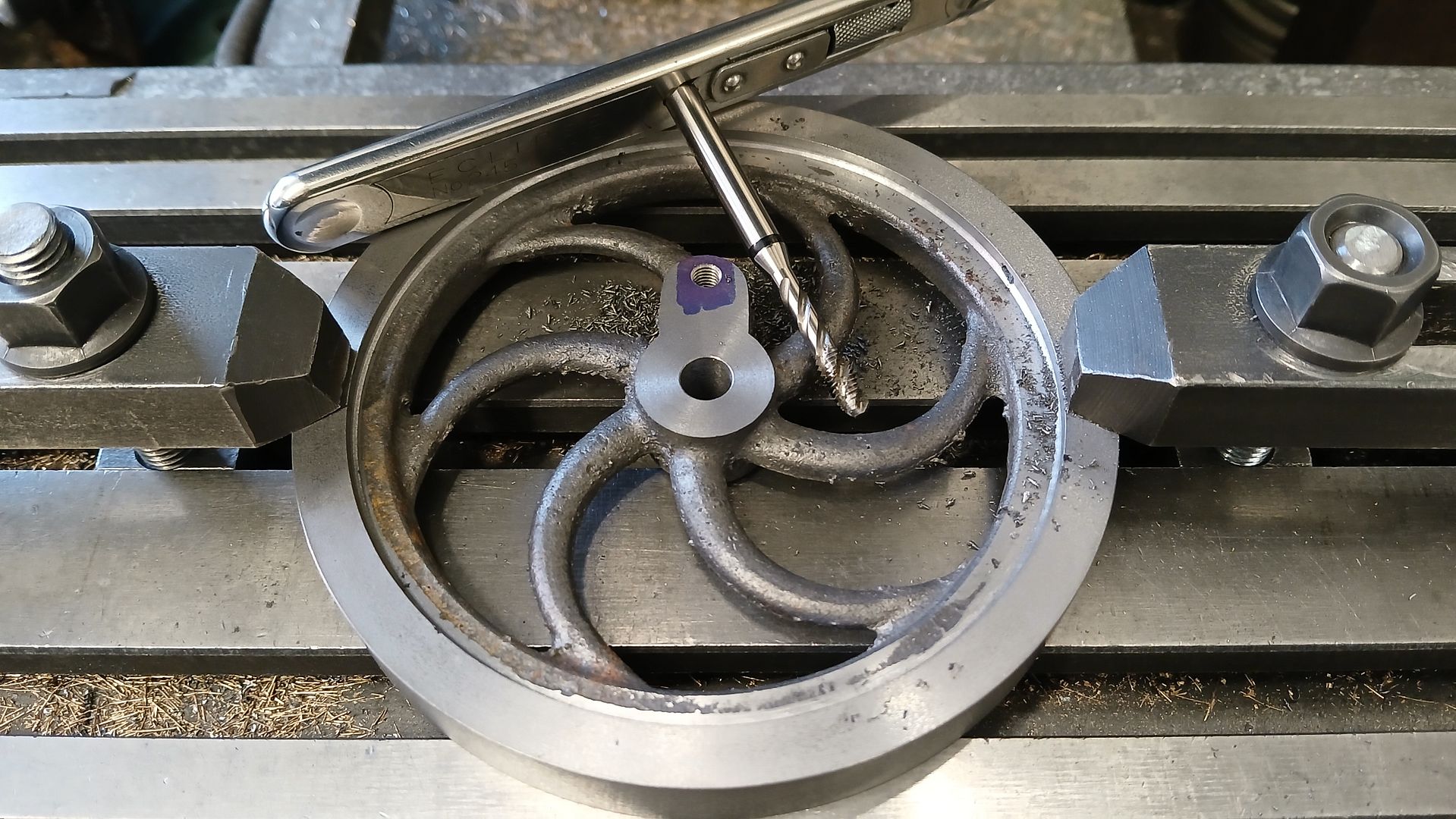

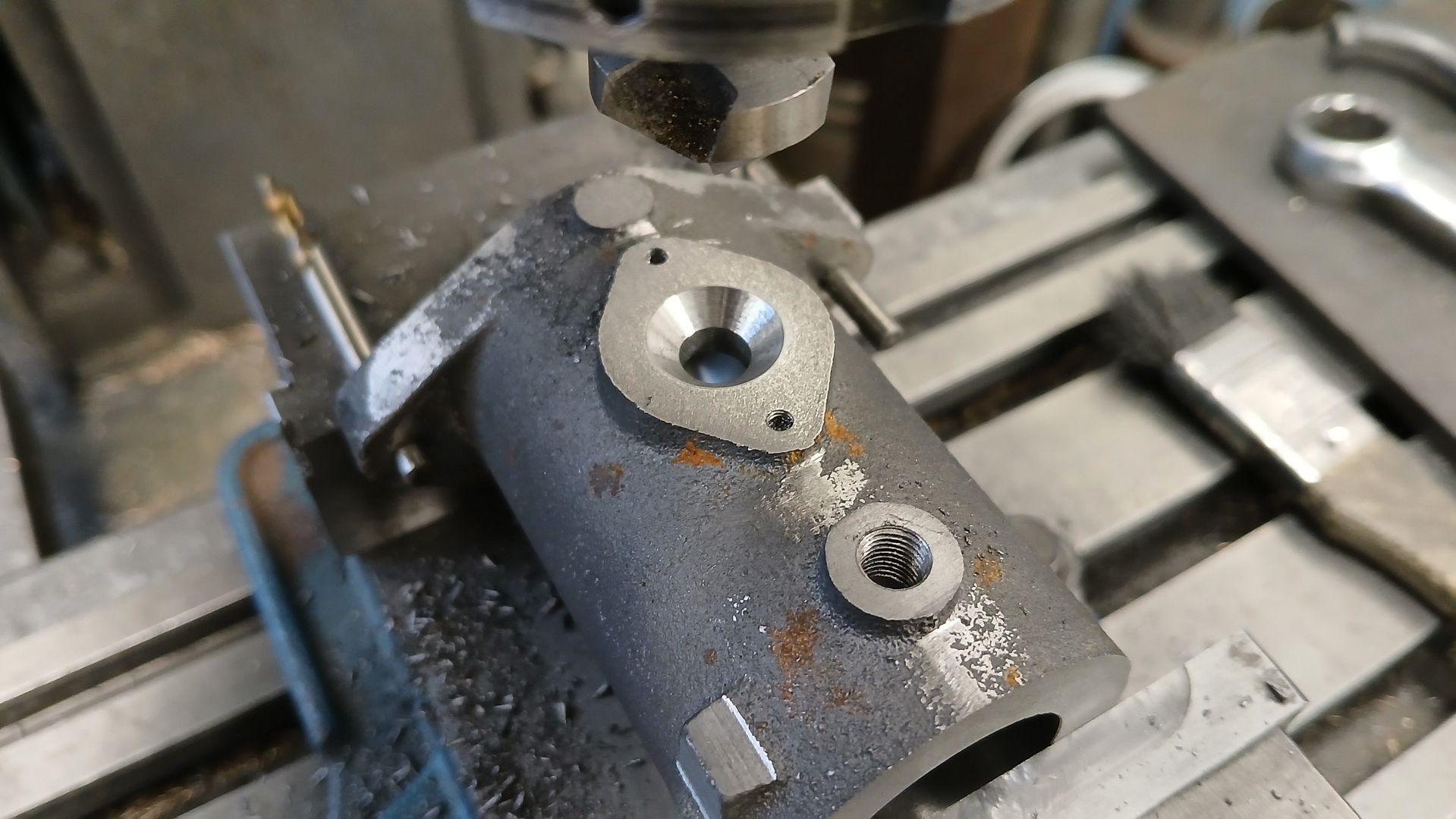

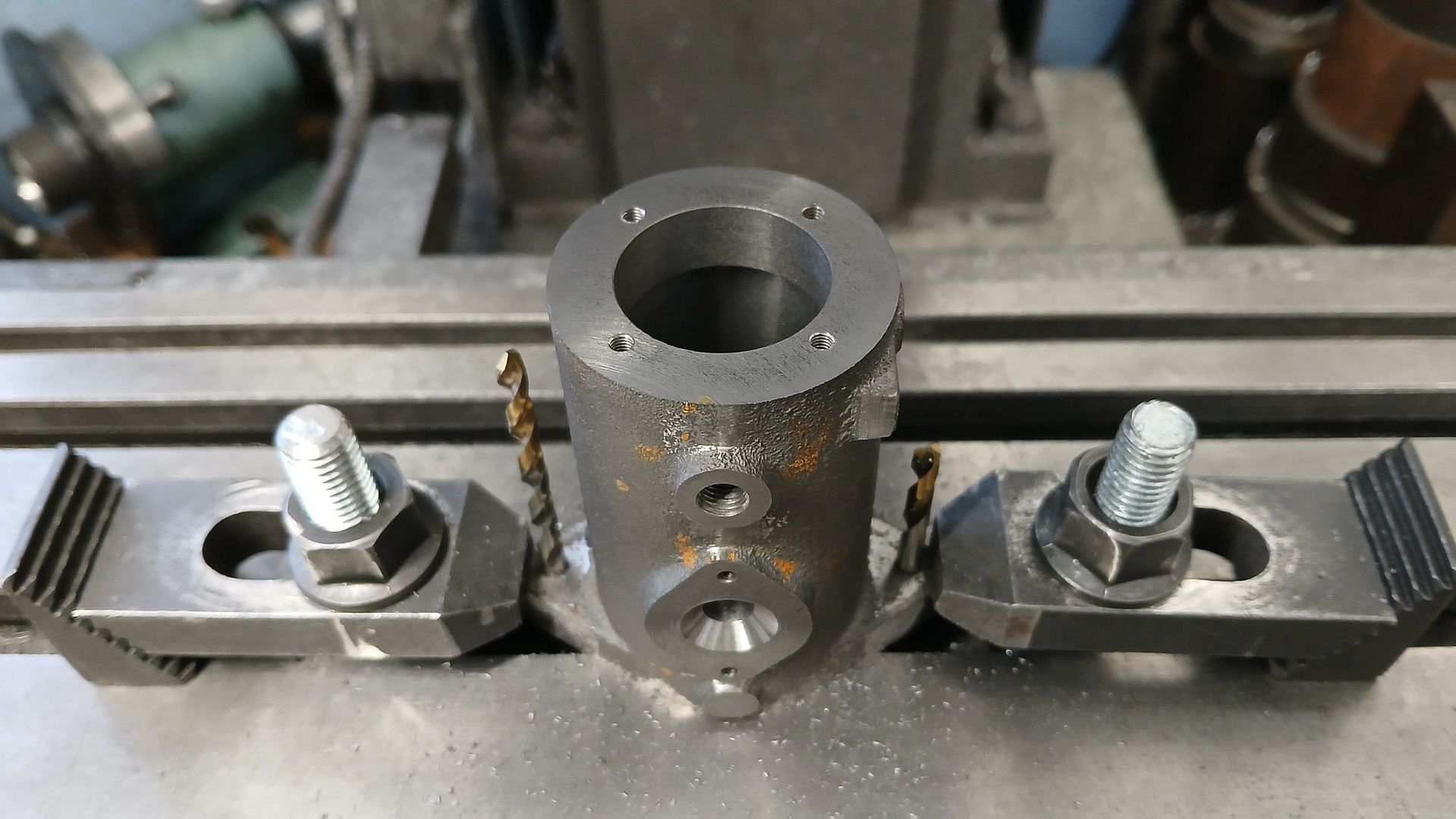

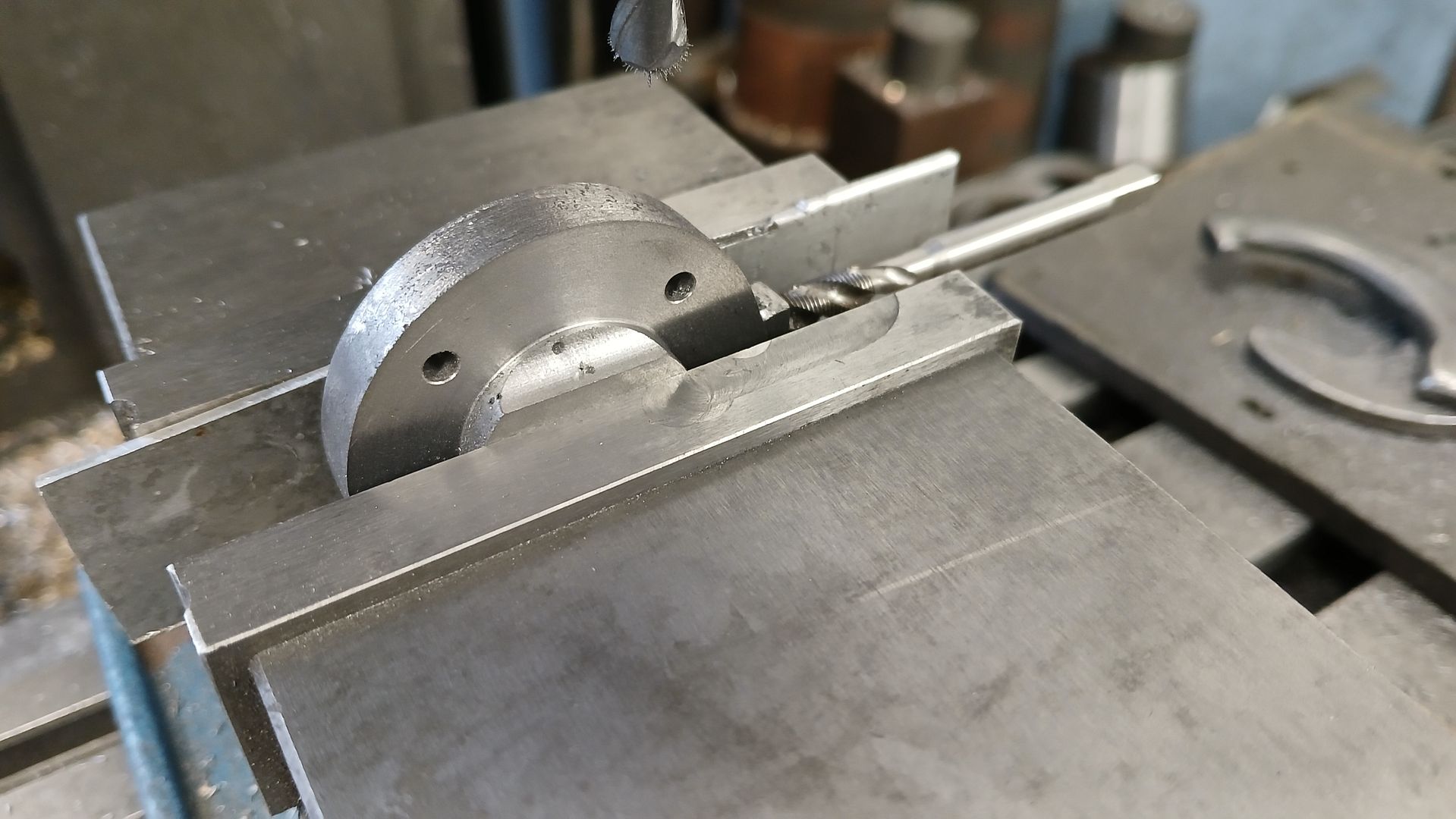

I then moved the 4-jaw to the mill so that the two mounting holes could be drilled perpendicular to the face of the flange

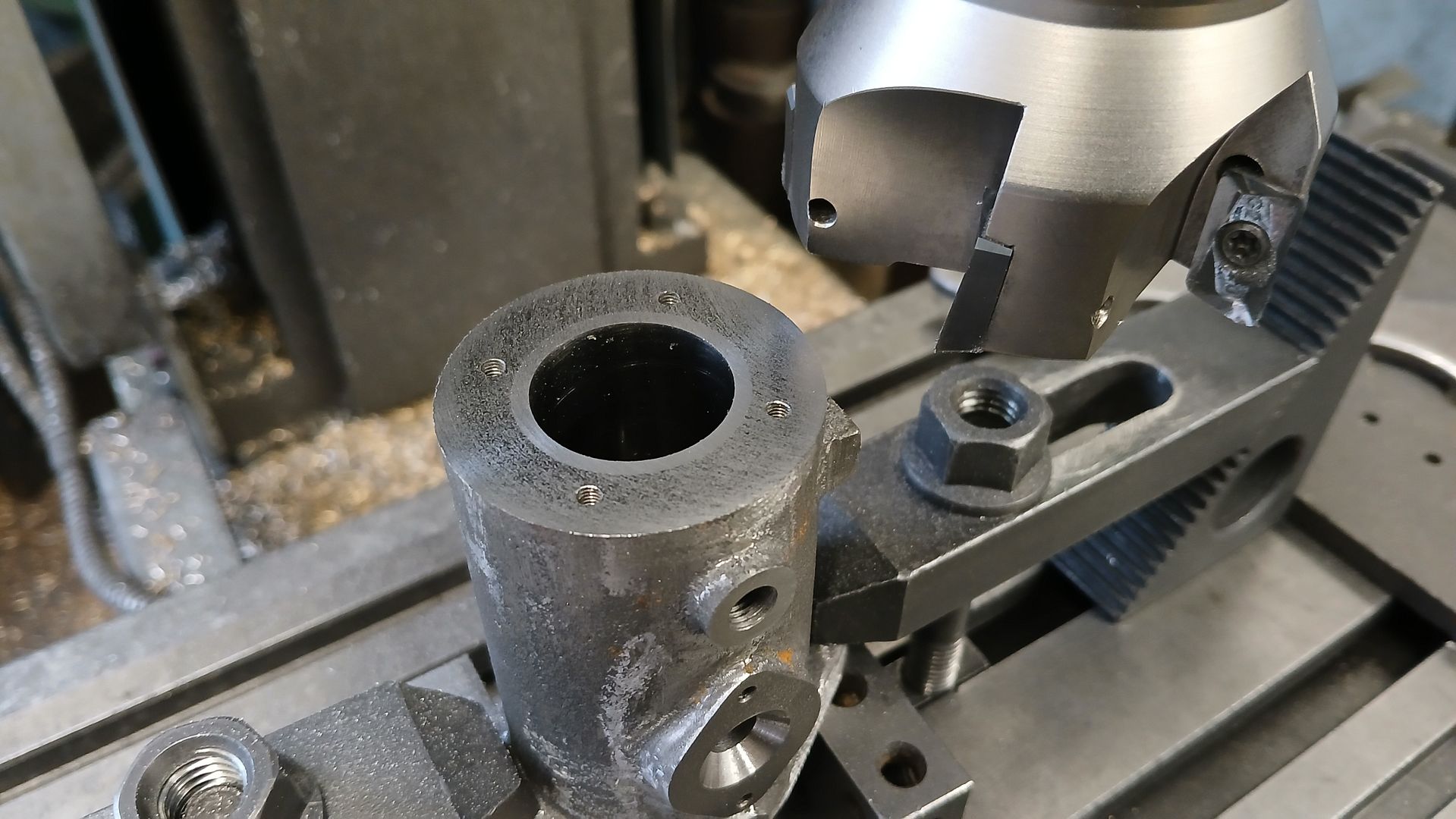

The head end of the cylinder was milled flat but I left an extra 0.5mm so it can be taken to final length once the liner has been Loctited into place.

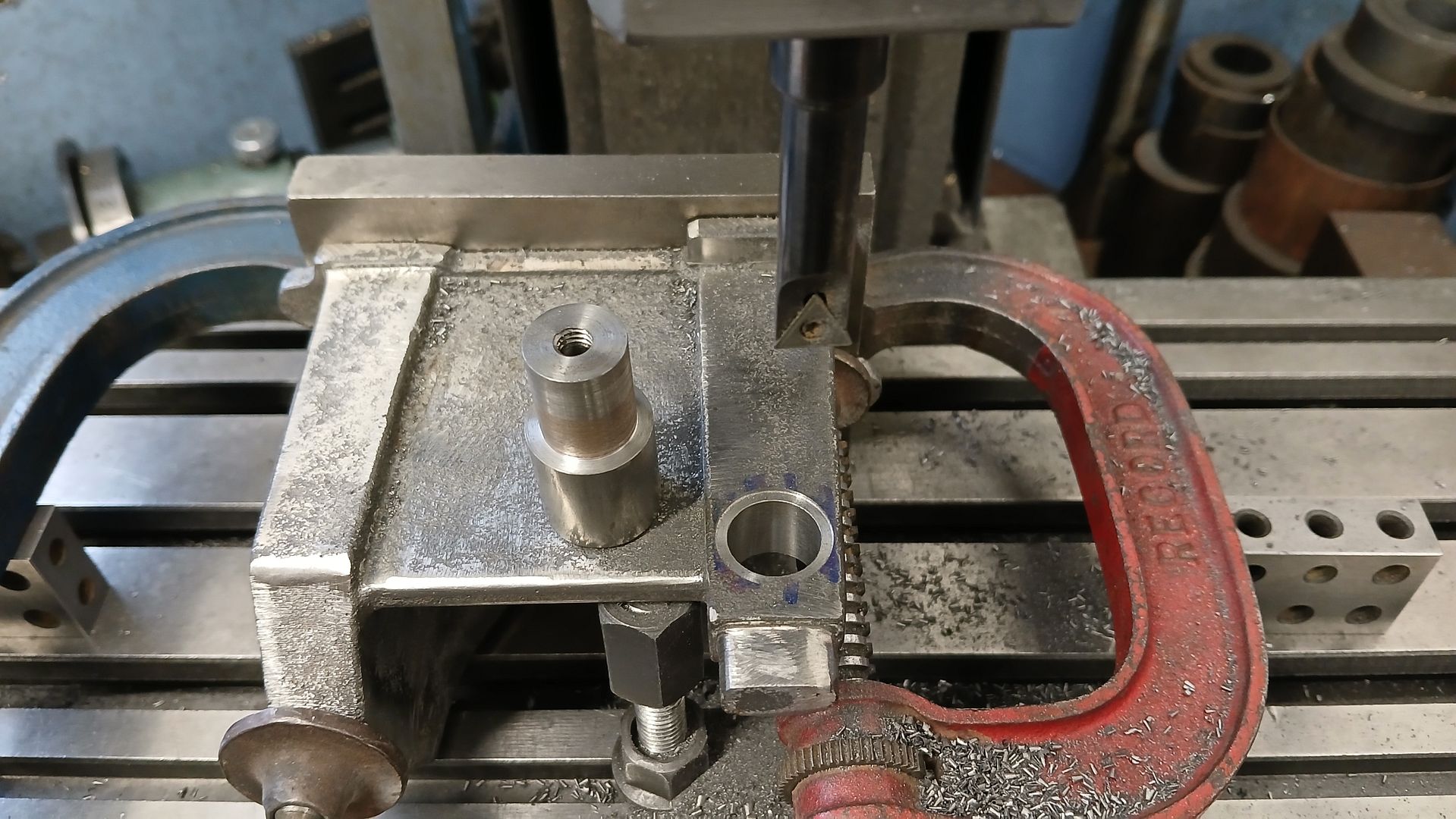

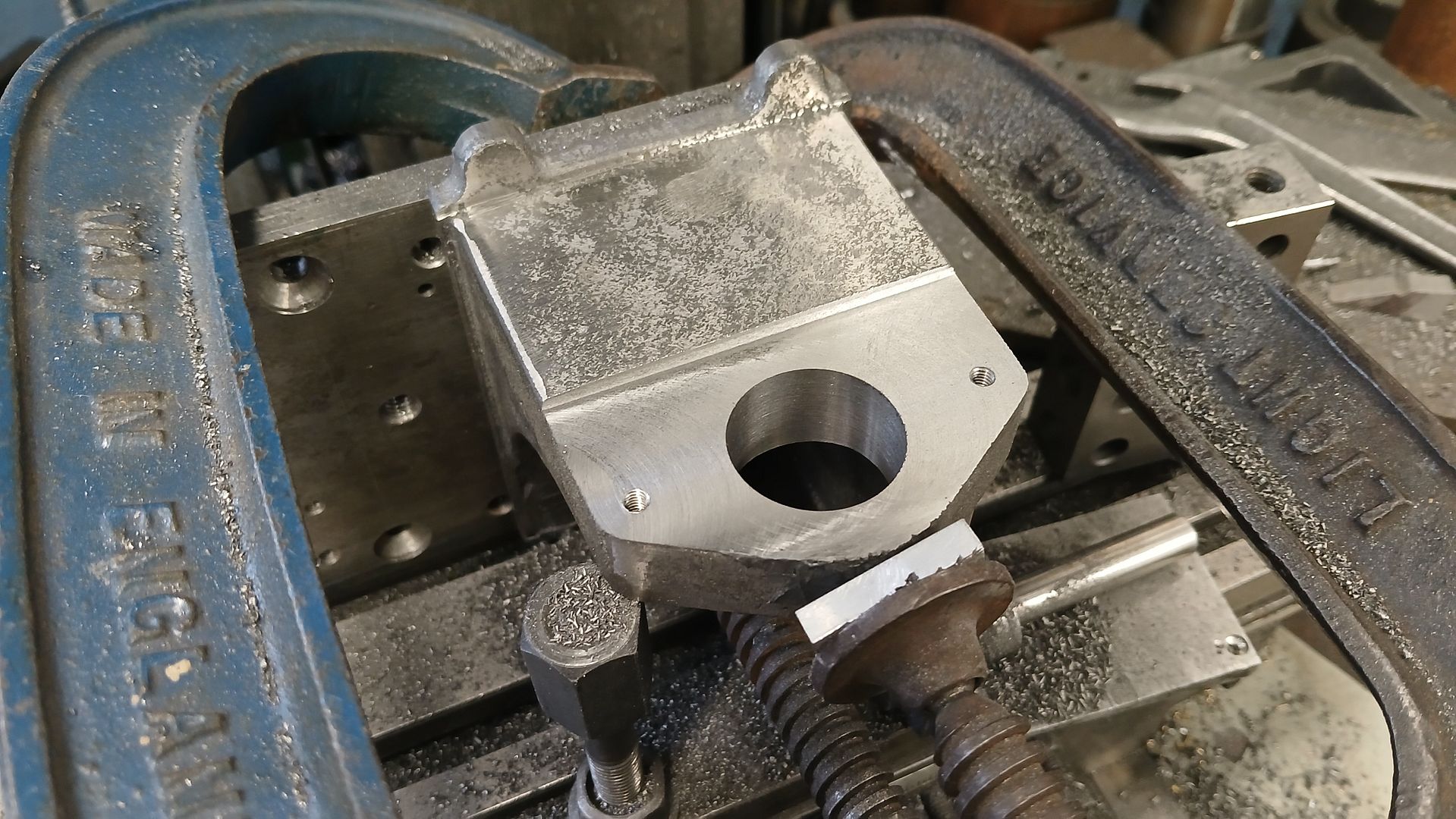

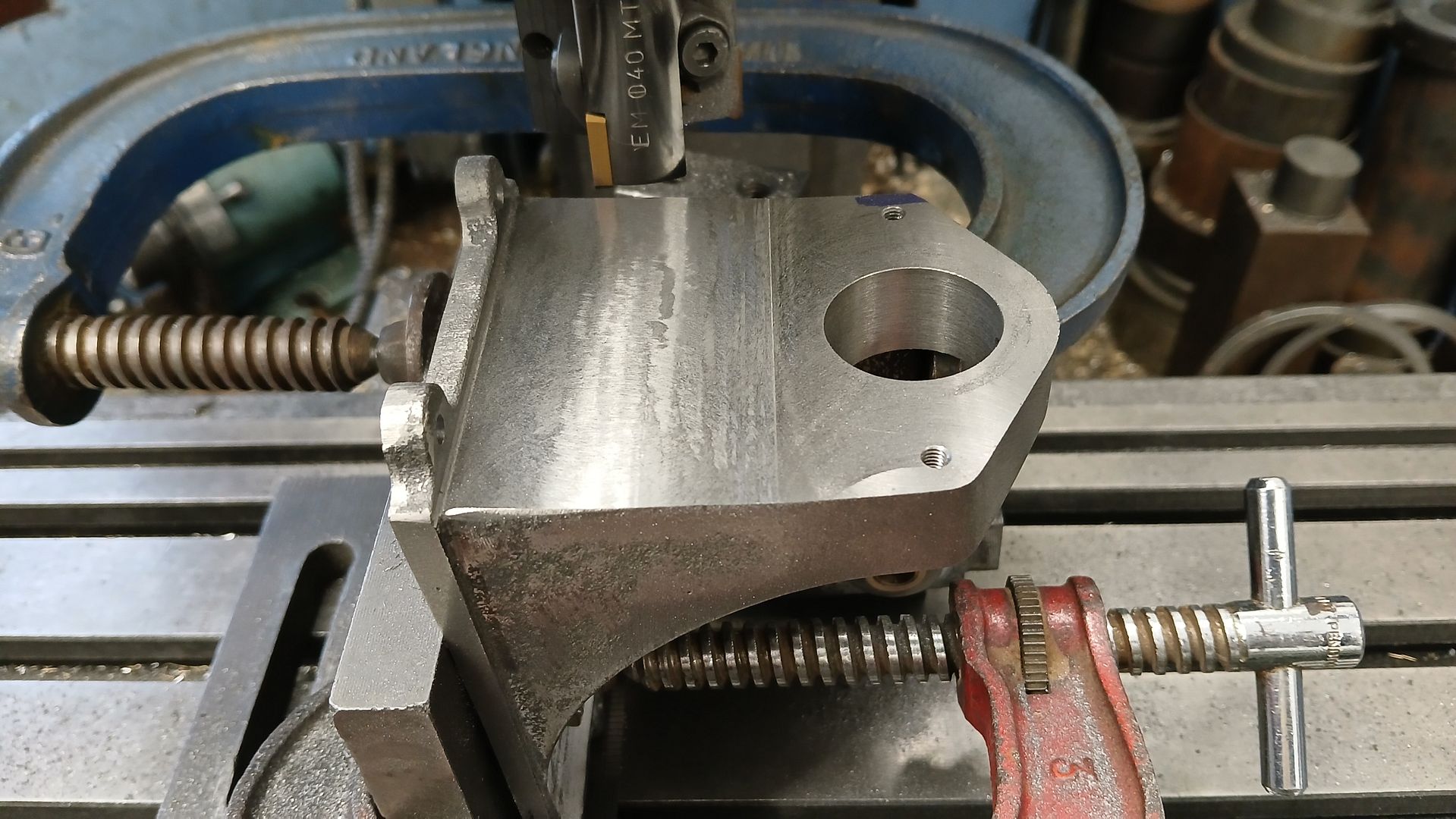

With both ends machined it was easy to hold in the vice and mill the various bosses down to height

The middle of the two water connections was located by holding a similar diameter rod in the chuck and moving the mill’s table until the position looked right. Then swapped the rod for spot drill, tapping drill and tapped M6 x 0.75. Though 1/4 x 40 would suit if using 1/4″ pipe. The other holes will be done once the liner is in place as they pass through it and the cylinder

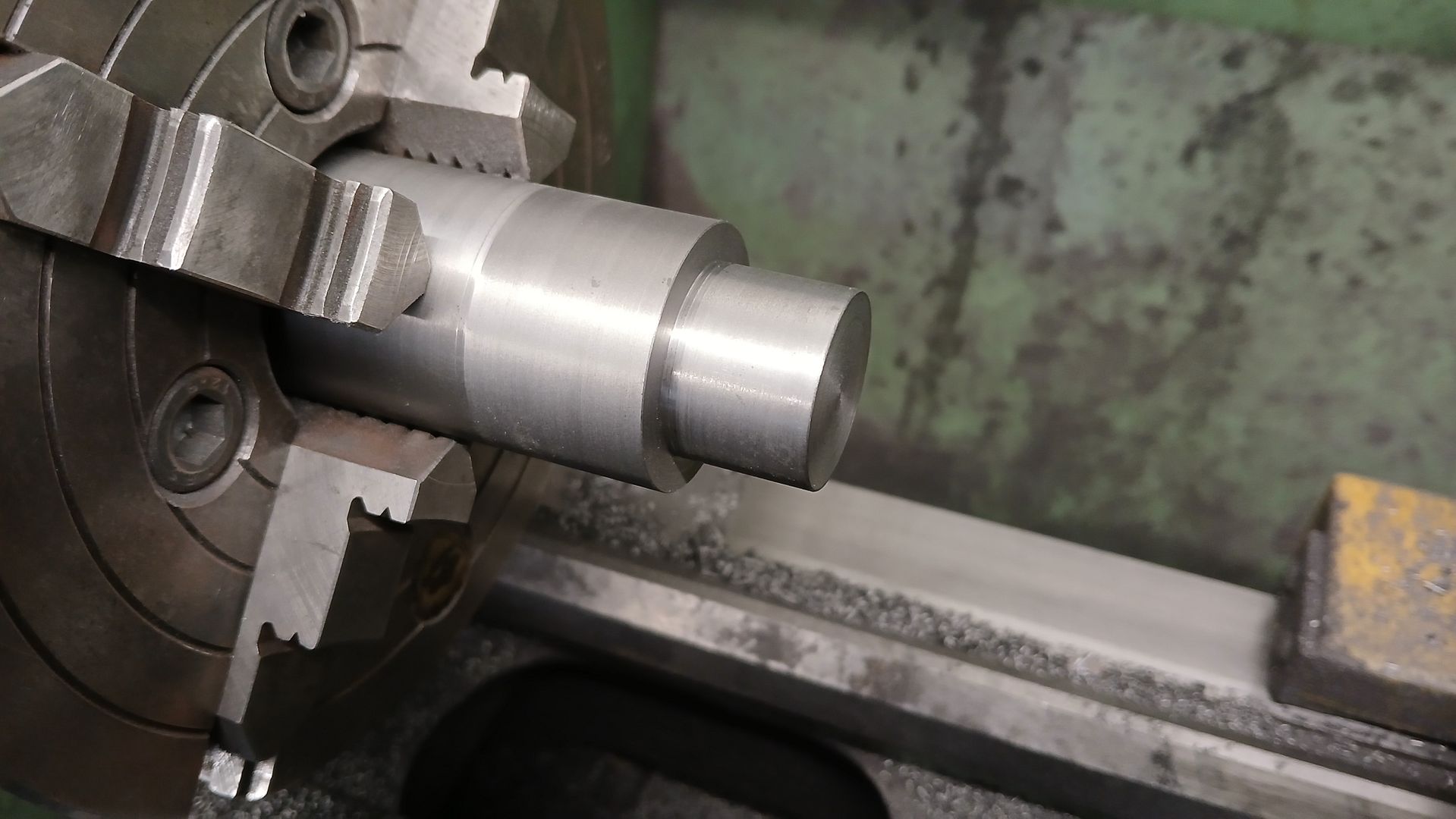

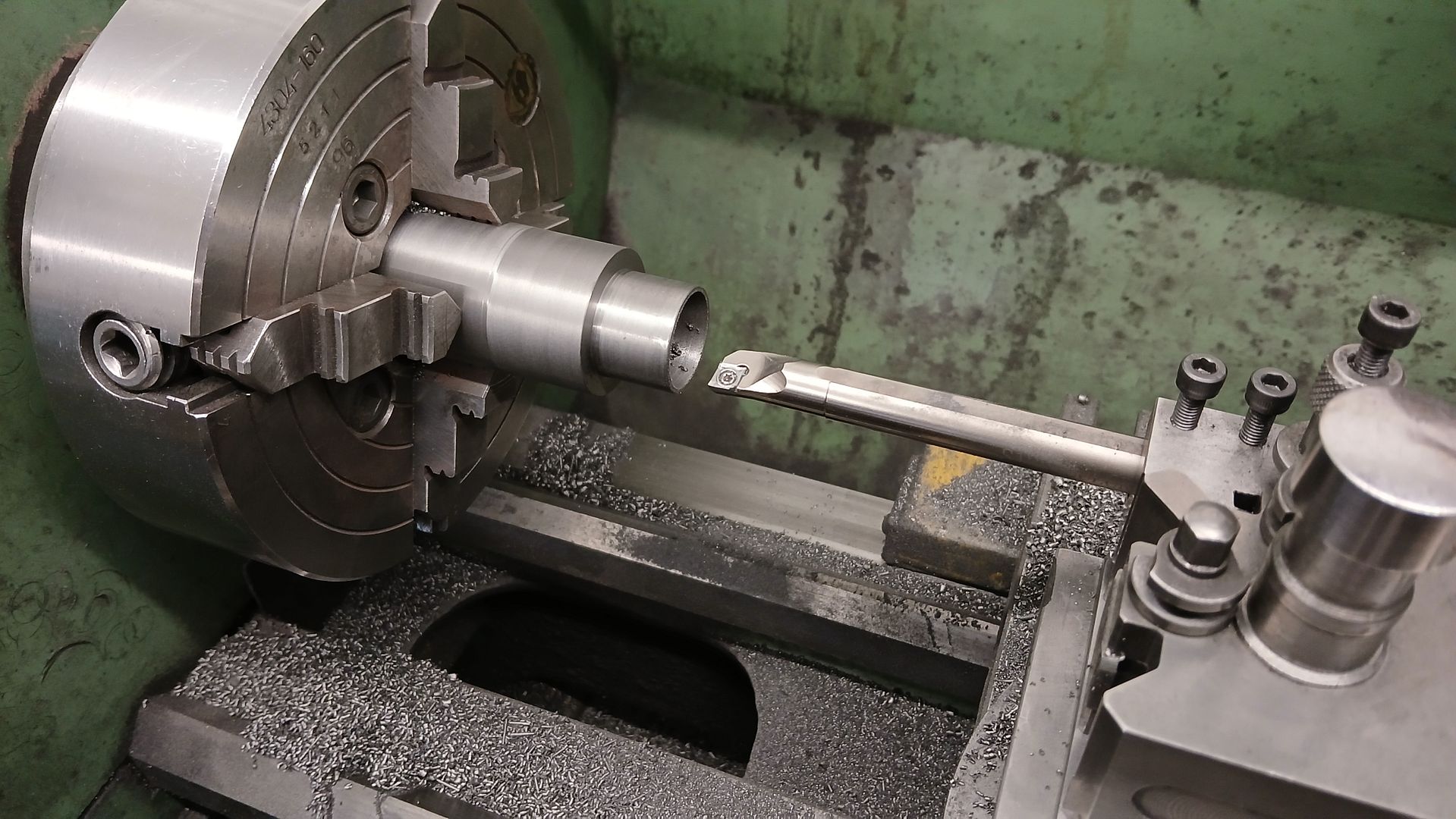

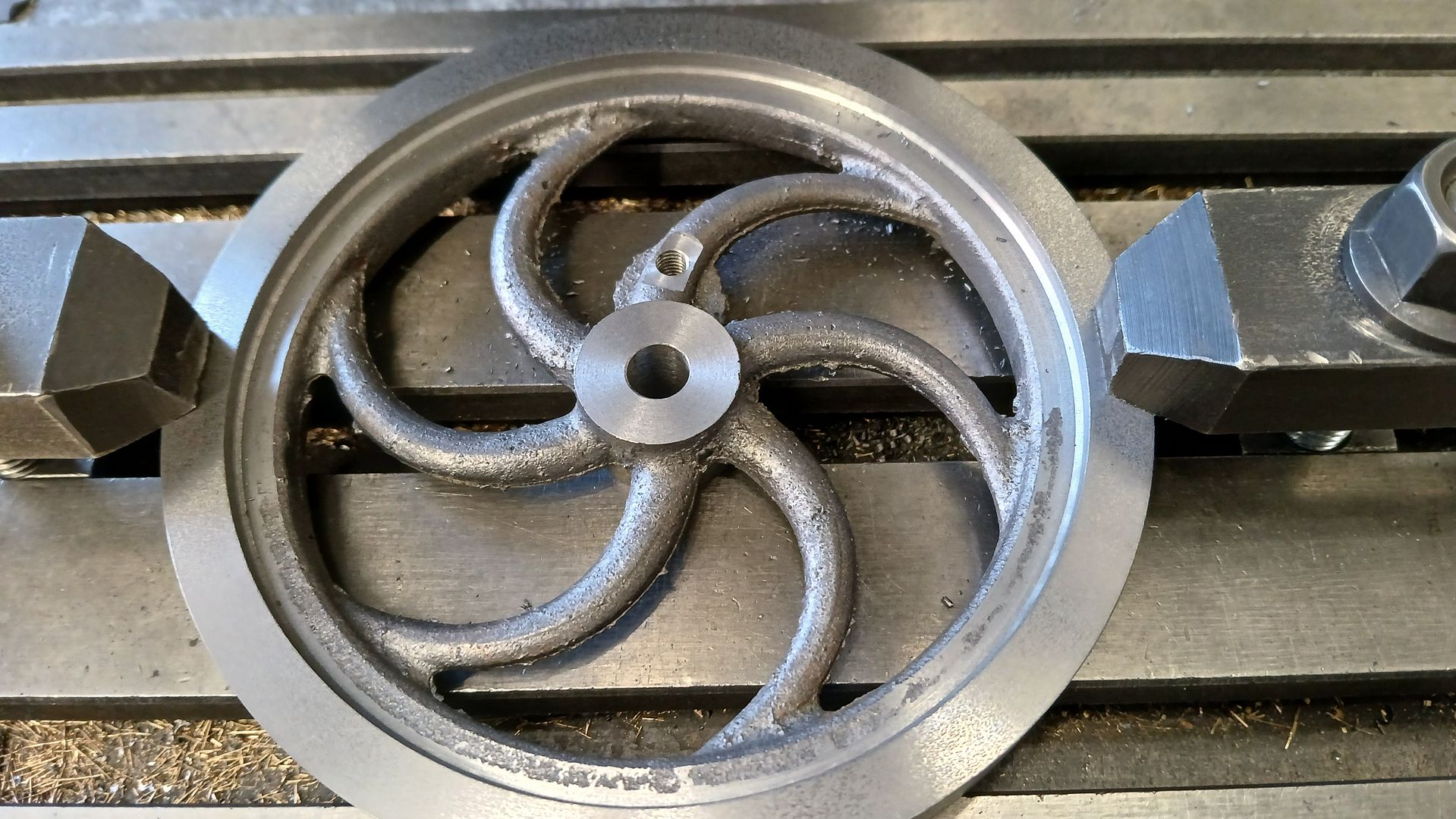

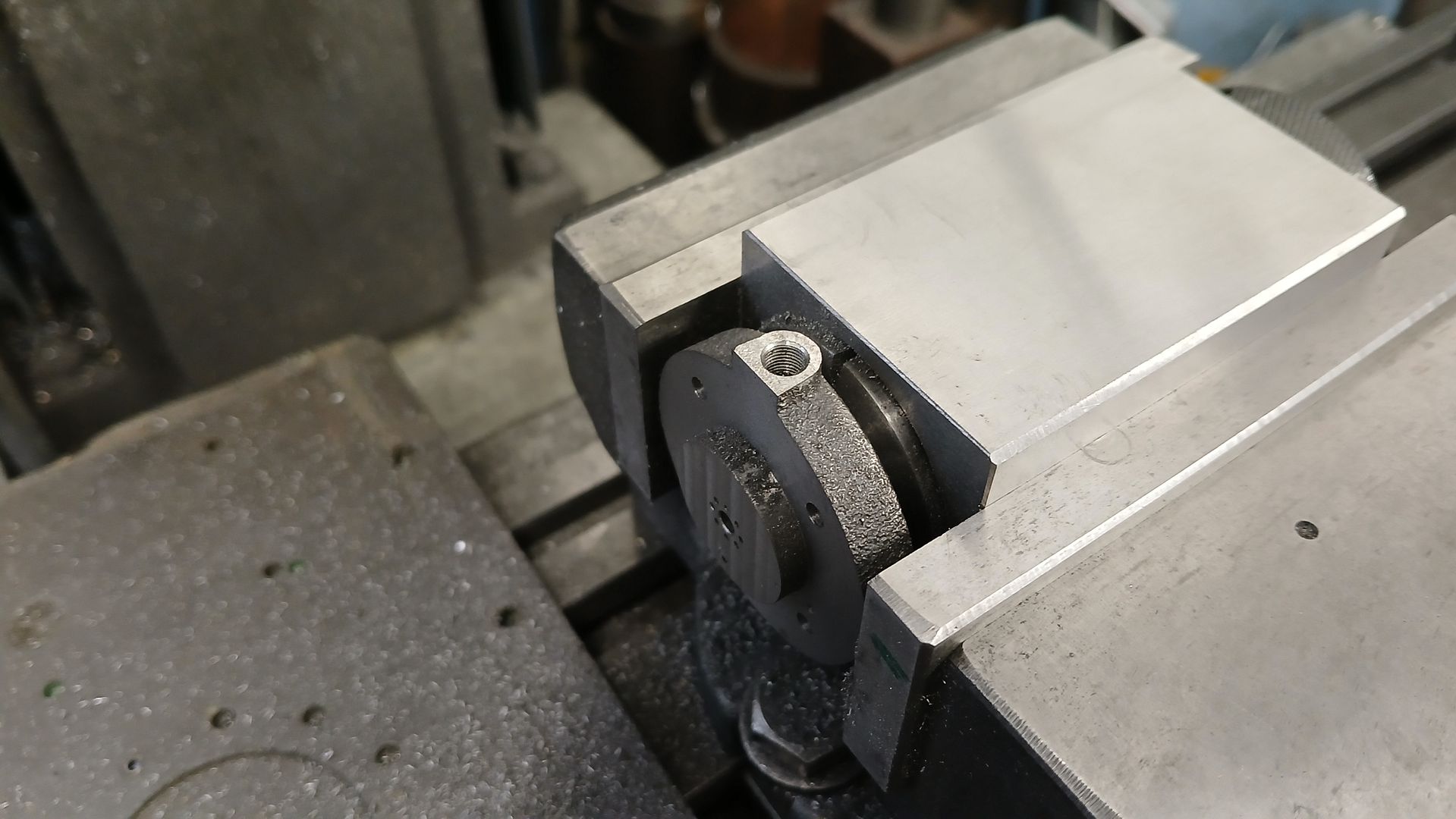

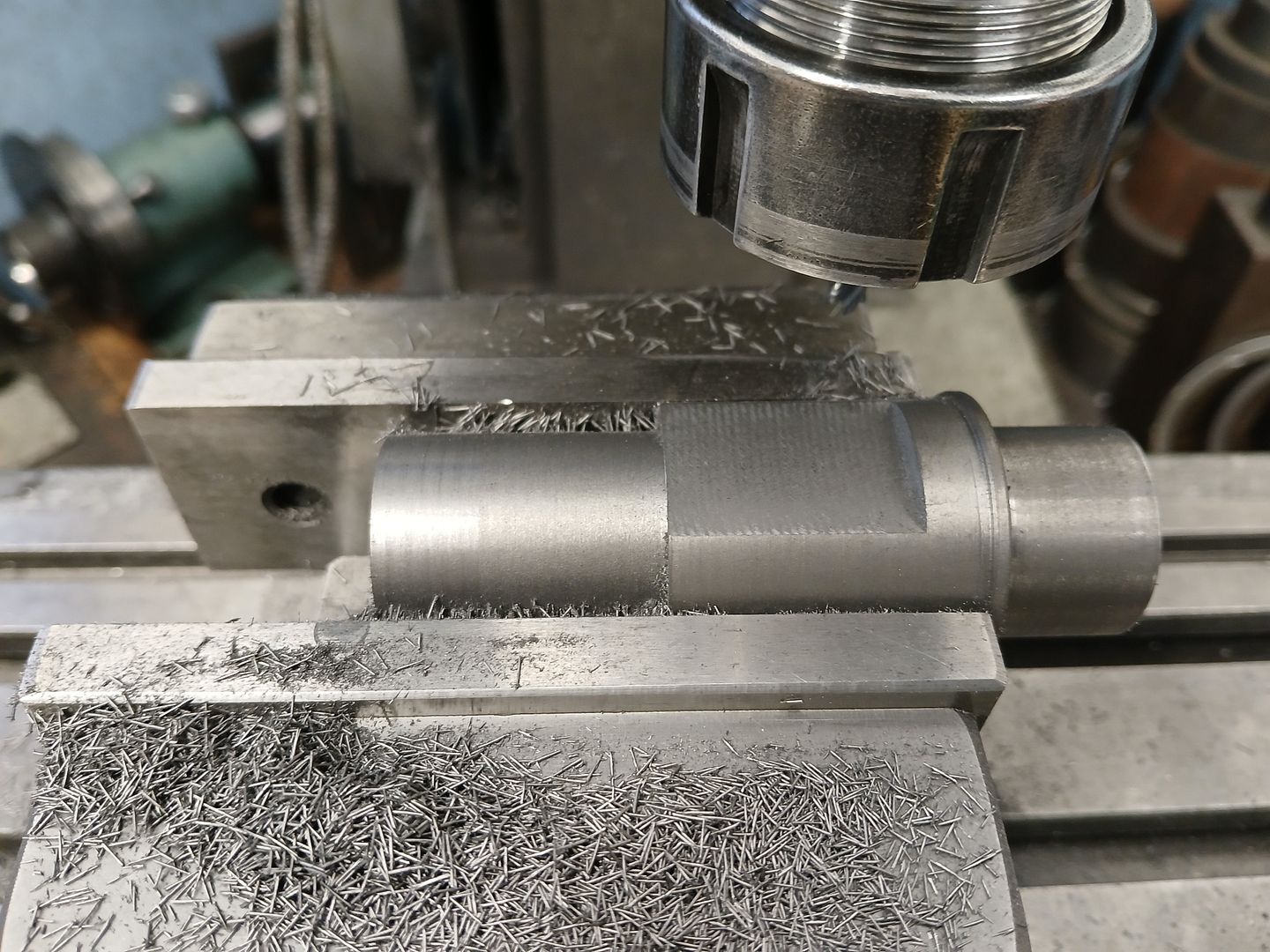

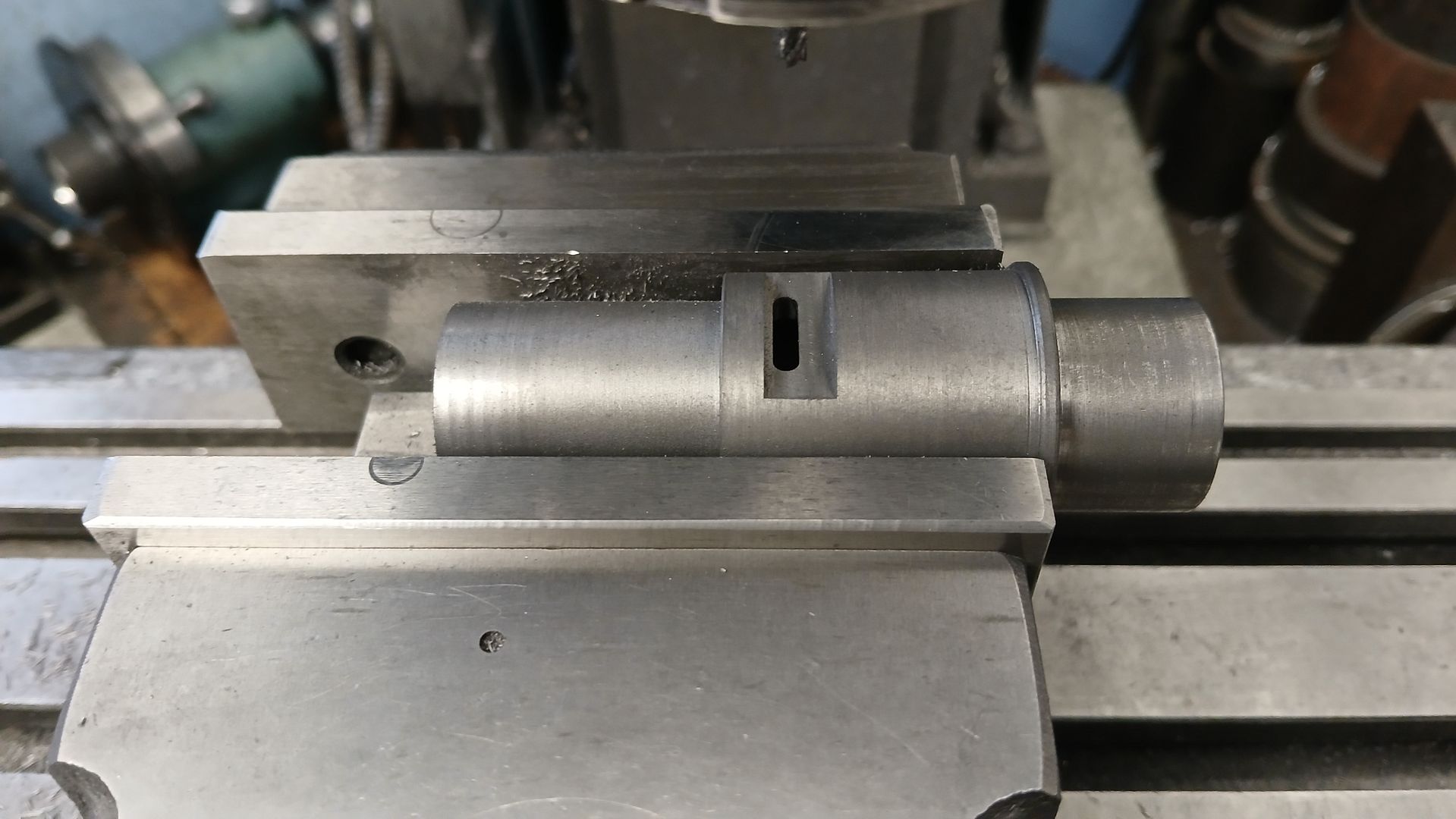

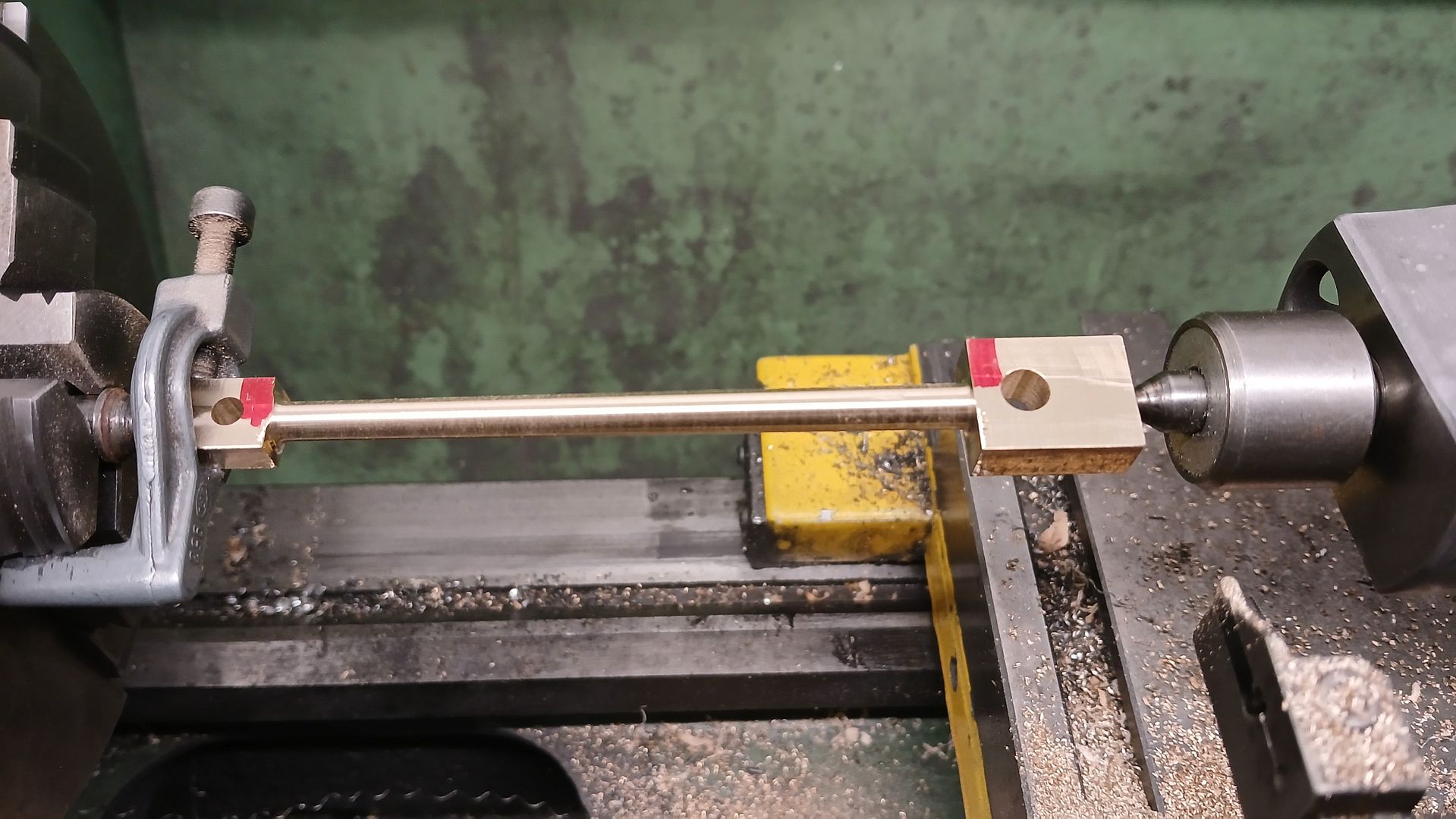

I then made a start on the liner, first roughing it down to 1mm over diameter which gave me a clean surface to hold while I turned the spigot that locates in the base.

At the same setting I bored the liner out to the required 22mm diameter.

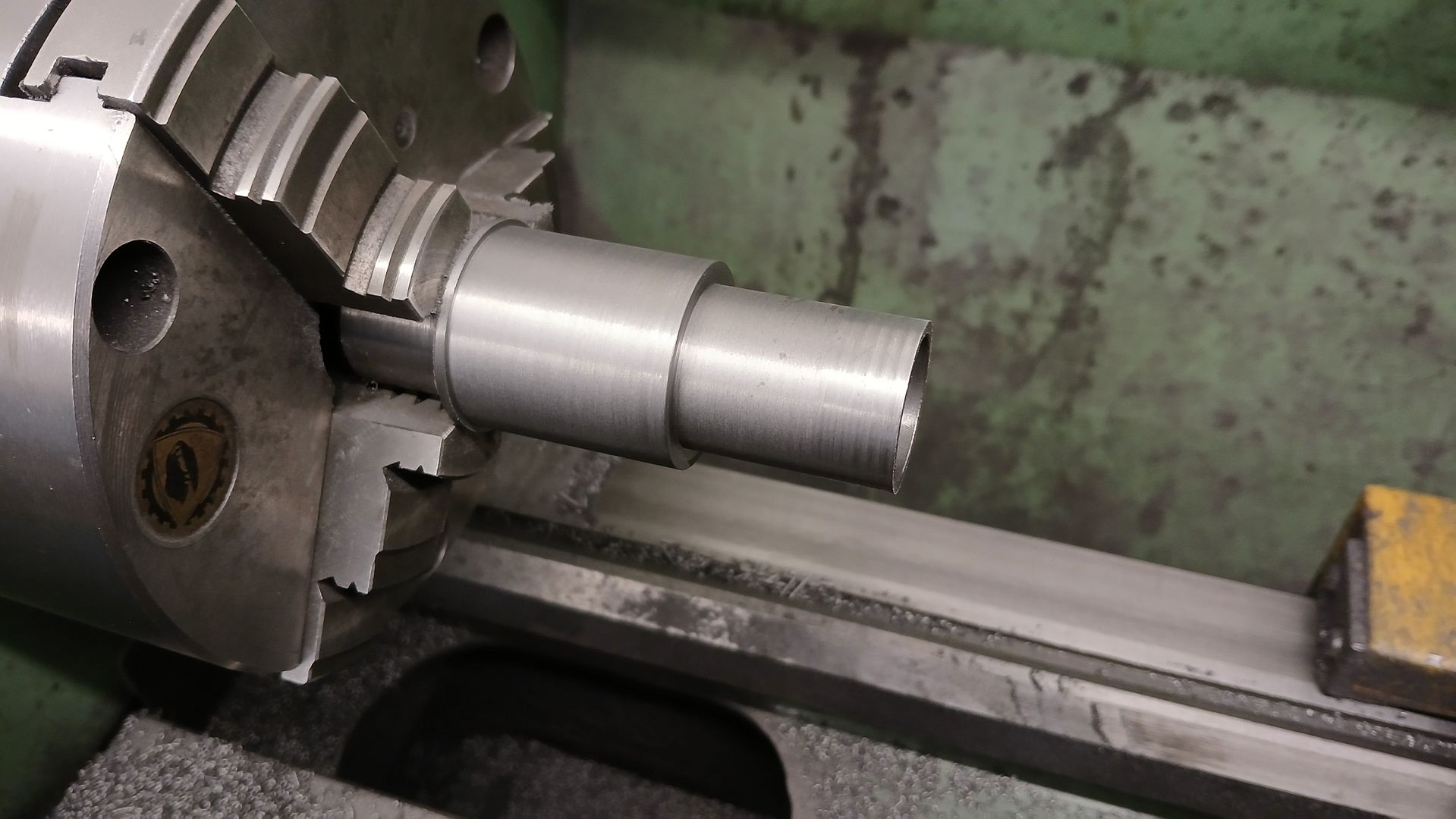

Then turned it round and did the 26, 33 and 35mm diameters using the cylinder to gauge the fits

JasonB.

JasonB.