Posted by Mick B1 on 28/04/2020 09:11:37:

Attitudes to Damascus barrels have varied with time. …

The original Damascus steel was made in the Near East between AD300 up until about 1750. The raw-material was Wootz Steel from India. Wootz and Damascus both have mythic qualities because in their time they were high-quality, and because we don't know exactly how they were made. Modern steel makers can easily get and hold high temperatures and pure materials, but how the ancients did it is unknown.

Damascus is made by repeated folding and forge welding a mix of different steel billets – the operation has to be done correctly several times, and is downright difficult in a primitive forge. Anyway, for about a thousand years, Damascus Steel was better than anything made in Europe. But it was rare, expensive, and much faked!

By the seventeenth century European steel-making had improved, mainly with the intent of producing good quality steel cheaply, rather than the best possible metal. The latter still depended much on the application of skill, expensive (pure) materials, and a lot of hard work. Steel made for the best sword blades was far more expensive than steel used to make working tools.

Technology moved on slowly, and for a long time steel was slowly made in furnaces producing up to a ton of steel per day, with lots of wasted heat. Then Mr Bessemer arrived with his converter, blasting out very good mild-steel hundreds of tons at a time, and using far less heat that traditional processes. Bessemer steel was far from perfect, but it could be used directly for structural purposes, and also as a pure raw-material for making tool and other quality steels. Most modern steel is made by an improved Bessemer-like technique, with some furnaces producing 13,000 tons of steel per day.

Damascus steel has an attractive characteristic pattern, which can be naively associated with 'quality'. Possibly a true sign of quality today, but far more likely it's cosmetic, done because it looks good, not for a technical reason.

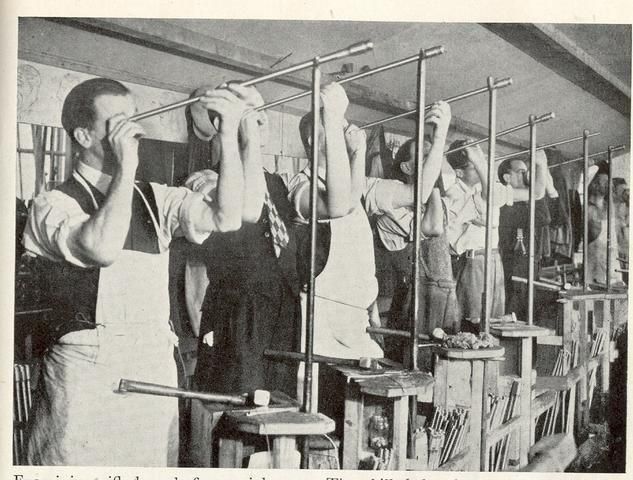

Hammer forging gun barrels is another example of a modern technique developed to reduce cost that also produces a superior product. Traditional rifle barrels went through several processes that inevitably left them with imperfections. Much inspecting and rejecting done! The final step with Lee-Enfield barrels was to hold them to the light and check internal reflections to see which way the barrel was bent. Any error was corrected by hitting the barrel with a mallet. Sounds crude, but it's an optical test that skilled men could use to correct unacceptable barrels to 'good' or 'excellent'. Sniper and competition barrels were selected from the best of the best.

Kaiser Wilhelm's Germany cheated by using machines to straighten their barrels!

And this method appeals to some:

Hammer forging removes the need for this and other labour intensive processes; the machine churns out consistently straight barrels, and they're stronger than the ordinary type. It's also possible to make them even tougher by forging from alloys that don't machine easily.

Dave

Edited By SillyOldDuffer on 28/04/2020 11:16:28

Brian H.