Had Another Go

Had Another Go

Home › Forums › CAD – Technical drawing & design › Had Another Go

- This topic has 358 replies, 22 voices, and was last updated 19 February 2025 at 22:51 by

Nigel Graham 2.

-

AuthorPosts

-

8 January 2025 at 21:15 #775798

Andy Stopford

Participant@andystopford50521It looks like you’re making good progress, Nigel.

In “Traction Engine Design and Construction” G.F.A. Gilbert suggests full-size practise was to make the clearance volume 7 to 12% of swept volume, and the passage area 5 to 10% of the piston area (I can’t find the reference for the latter, so I might have got that from somewhere else).

Previous contributors to this forum have suggested that full-size proportions will correctly work with models.Of course, as you mention, actually fitting sensible sized walls, etc., between the passages can be a challenge at small scales – I’m currently wrestling with designing the very complicated steam ways for a Fowler Z7S – what looks like a decent wall thickness on the screen can turn out to be 0.5 mm or something ridiculous when you actually check what you’ve drawn!

8 January 2025 at 22:11 #775830Nigel Graham 2

Participant@nigelgraham2Neil – Impressive! 3D printed?

Andy – Thank you for that guidance. I’ll examine my dimensions so far. I’ve not yet done the metalwork – I want to make sure I remove the right swarf from the right places.

8 January 2025 at 23:53 #775849Charles Lamont

Participant@charleslamont71117One way to think about modelling this kind of internal detail is to construct it all, here the ports and passages, as a complete separate part and then use a boolian operation to subtract it from the cylinder. It is particularly useful when modeling cored holes – just model the core as a part in its own right and then subtract it from the body.

9 January 2025 at 07:08 #775858 JasonBModerator@jasonb

JasonBModerator@jasonbUnfortunately Nigel’s Atom does not have Boolian add/subtract ( only pro & Expert) though as you say good for coring complex shapes.

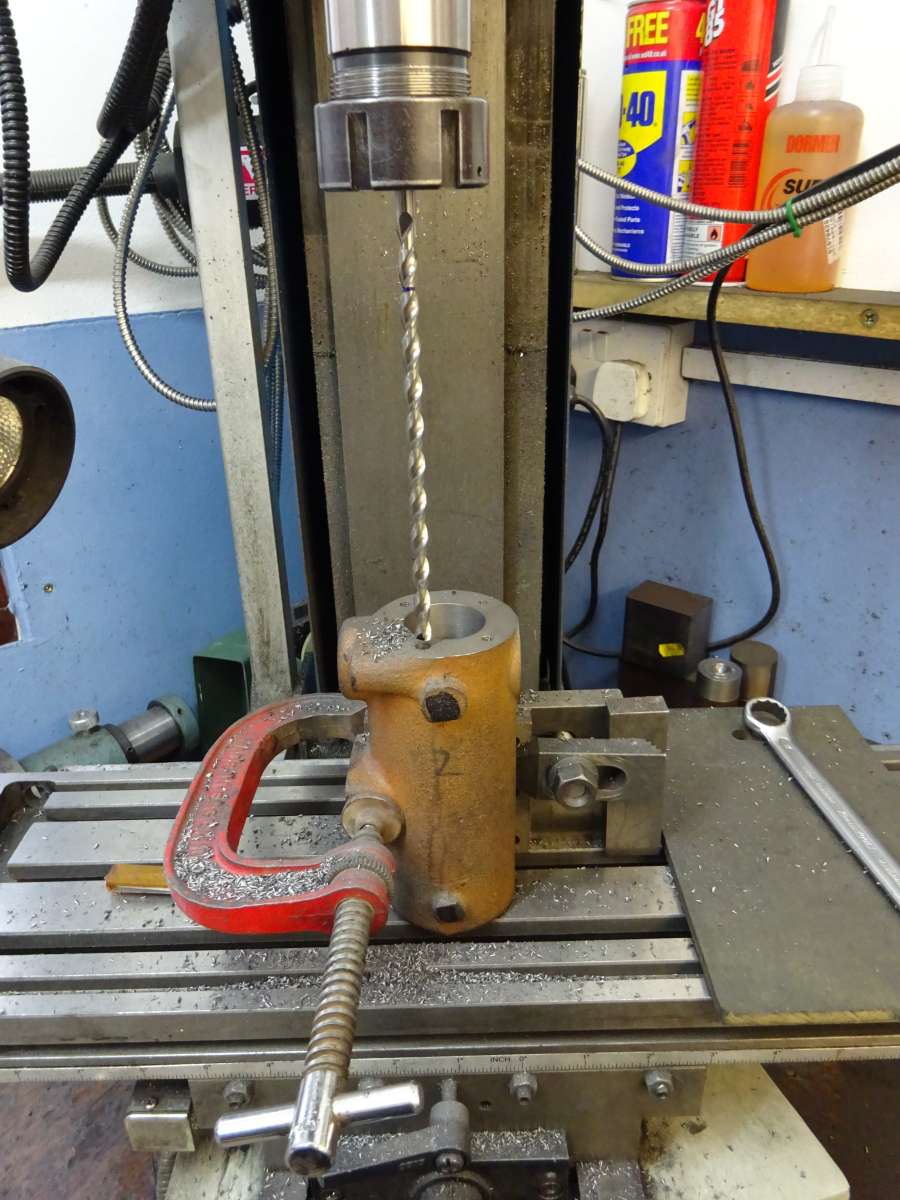

I quite often have to go with 1mm between cylinder and passage on the smaller engines so proportioning that to your larger engine should not be a problem. That cylinder in my post above only has 1mm between the two. As for some of the IC engines they can have some long water cooling passages, this one is about 120mm deep (mark near top of drill) and about 2.5mm wall left.

As for cross sections also consider the sizes of your inlet and exhaust pipes which may be where the restriction is smaller and also if your ports will be fully uncovered.

9 January 2025 at 16:45 #775977 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattNeil – Impressive! 3D printed?

Andy – Thank you for that guidance. I’ll examine my dimensions so far. I’ve not yet done the metalwork – I want to make sure I remove the right swarf from the right places.

A resin print, even with the Mage Pro I had to split it into three parts. The surface finish on resin parts is exceptional.

10 January 2025 at 01:01 #776130Nigel Graham 2

Participant@nigelgraham2Well, processes like that are not for the like of me but I am impressed by them and by the skill necessary to operate any CAD/CAM system from drawing to product.

…..

I turned away from wrestling with my cylinders for the moment, as I was beginning to become bogged down.

So tried to draw the wagon’s basic chassis, in Alibre Atom.

That proved too hard.

It is made from 50 X 25 X 25mm hot-rolled steel channel, close to scale overall as far as I could determine, though over-scale in thickness.

Easy to draw a near-enough section and extrude that to length. So far so good….

Rather than risking trying a cut-and-shut technique with my “welding” and the impossibility of producing a decent-looking result, I bent the longitudinal rails to their elongated ‘Z’-form with a narrow-gauge railway rail-bender. This gives rather vague turning-points but careful use of rule and clamped-on straight-edges determined them closely enough.

I tired two different approaches to drawing them.

For the first I drew one flange full-length, extruded to thickness, built the web to half-height (a battle itself, with three separate sections for the web), then mirrored it to the full section. Then discovered I’d “bent” it the wrong way!

Scrapped that attempt, and tried to Assemble it from three lengths of channel.

I calculated the angles for the mating ends, and trimmed them. Angles not visible by eye.

The trouble is, I still can’t manage these planes and orientations. Despite all planning I cannot set the object on the right plane and often it faces the wrong way as it develops. Switching from model to sketch view gyrates it and the view planes wildly into any but the wanted way. Is it possible to rotate an object about its axis against fixed view planes?

One length didn’t seem to want to Save the end modifications, but eventually I had three pieces with their joint ends marked by little holes “drilled” through both flanges next to the joints. (Holes and joints not in the real rails.)

Then to try to assemble them…. More chaos. Each length of channel was a modified copy of the first so theoretically all on the same planes – probably the wrong ones, but at least the same wrong ones. The imported Parts still threw themselves everywhere, facing anywhere, at any attempt to control them. The Constraints menu, as baffling as ever, offered only Concentric constraints. The pop-up error messages were the sort comprehensible only to Alibre’s writers.

Then I realised that even if I had modelled the long rails successfully, I’d fail in “fitting” the cross-members.

Of the four, two are inside the tapering section of the chassis. The third further aft is at least inside the parallel section. When I measured their lengths and distances from the real rail ends, I forgot I cannot set objects to distance along featureless surfaces in a 3D CAD model.

The fourth, right at the back, spans the full outside width of the chassis, so presumably the rail ends should constrain it; but I’d failed to model the rails anyway.

I gave up and closed Alibre without saving the hopeless mess.

Being ambitious is always wrong. Having successfully, experimentally modelled a straight length of channel and mirrored it a set distance away, I thought the bent chassis rails would not be much harder. They proved extremely difficult as extruded single parts, and impossible as assemblies of three lengths of channel.

10 January 2025 at 07:17 #776141 JasonBModerator@jasonb

JasonBModerator@jasonbYes you can move things about to look at any angle, either both mouse buttons down and move the mouse. Or use the icons at the top to view from different angles. However the reason Atom move things about is so that when 2D sketching you are looking straight at the “paper” If you start moving things about it would be like resting the sid eof your head on the drawing board and then trying to draw.

Re Assemblies. Assemble the three parts and save that as an assembly. You then don’t have such a worry about adding the cross pieces to them as that can be done as a separate assembly just like the real thing.

I’ll have alook and see if I kept any of the parts from when I last showed how to do the chassis rails.

10 January 2025 at 08:06 #776149David Jupp

Participant@davidjupp51506Each length of channel was a modified copy of the first so theoretically all on the same planes – probably the wrong ones, but at least the same wrong ones.

Nigel – I might be reading too much into your words here, but if ‘modified copy’ means you copied the file and then edited it, that will cause problems when you put the parts into an assembly.

Don’t copy Atom3D files, instead open a file then ‘Save As’ from inside the software, to create a new file with the current content (you can edit this to modify, or you can do the editing prior to the Save As). If you have copied files – this can be fixed afterwards (message me if you need to know how).

Chassis rails with gentle bends – could be done as a single feature using Sweep, or it could be built up from straight extrudes, and revolves to do the bends.

As for ‘fitting cross rails’ – you can use geometry from one part in an assembly to help modify another, this is possible even in Atom3D. This is done using ‘Edit Here’ mode and using ‘Project to sketch’ to transfer (say) section profile of one member into a cut feature on end of another. This is in the Help file, I’m also happy to show in a screenshare.

Part at ‘wrong’ orientation in assembly – remember you can hold down the Shift key, and drag with the mouse to ‘free rotate’ a part in the assembly space into roughly the right orientation. Final positioning is best done with assembly constraints. There is also a ‘precise placement’ tool which lets you specify exact moves and rotations (access this from ‘component placement’ icon on the assembly ribbon).

10 January 2025 at 09:03 #776151 JasonBModerator@jasonb

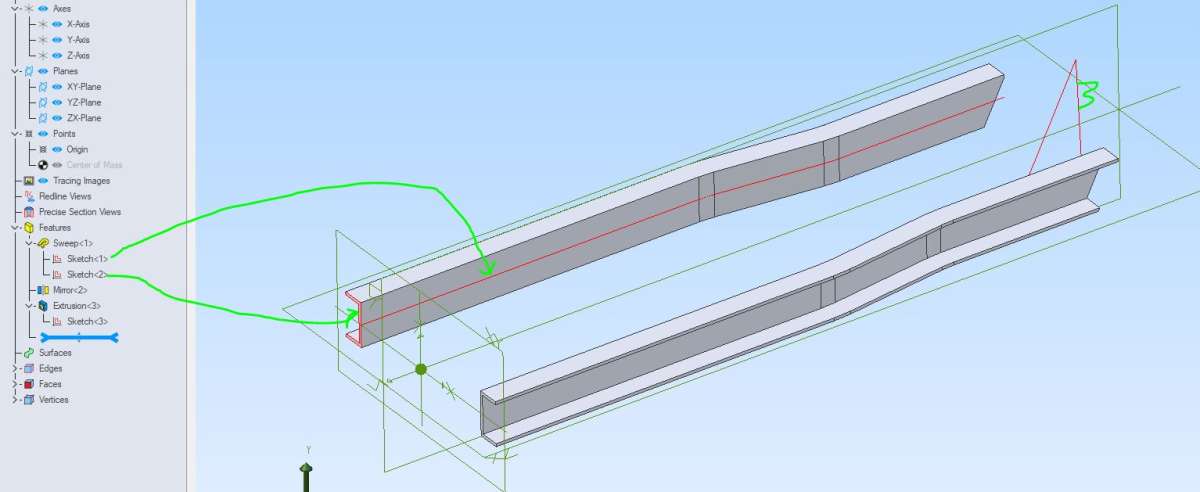

JasonBModerator@jasonbAs David said your lazy Z shape lends itself to a sweep of the basic C section along a sketch that can be the inside edge of a rail. Mirror to get the pair and then another sketch to do the angled cut at the front.

10 January 2025 at 09:48 #776156

10 January 2025 at 09:48 #776156Nigel Graham 2

Participant@nigelgraham2I did make the copies as independent files, because I thought, rightly or not, that you can’t create a set of separate parts on one Part drawing.

The bends in in the rails are gentle, going through only about 4º, of unknown radii, but very short accidents of the process. The bending-tool was a large screw pushing against the steel in a wide gap between two fixed arms, so there is no radius control.

The critical areas are all straight. For the one case where the bend starts behind a bracket bolted to the web, I made a stepped spacer to fill the gap. This was accidental as I could not possibly have predicted the bend forms, nor that the bracket’s eventual version would take the shape necessary and overhang the curve.

My plan was to draw one complete rail then make its fellow as a reflection, and I had worked out how to do that.

I wanted to be able to model that tapered area as that will hold the engine and transmission in the chassis, and I need work out how as the gears will be supported partly by one of the angled portions.

I suspect the full-size vehicles narrowed the chassis forwards of that and over a very short distance, so the front springs and the gear-frame are on the parallel parts of the chassis, but cannot see that from the photos. Nor think how the manufacturers would have done that, short of either pressing them hot, or cutting the rails into three straight parts and joining them in some way.

Anyway the upshot is more delays in the project that’s already taken far too long, and knowing I will probably never be able to create 3D CAD models of assemblies of two or more parts.

10 January 2025 at 10:38 #776170 JasonBModerator@jasonb

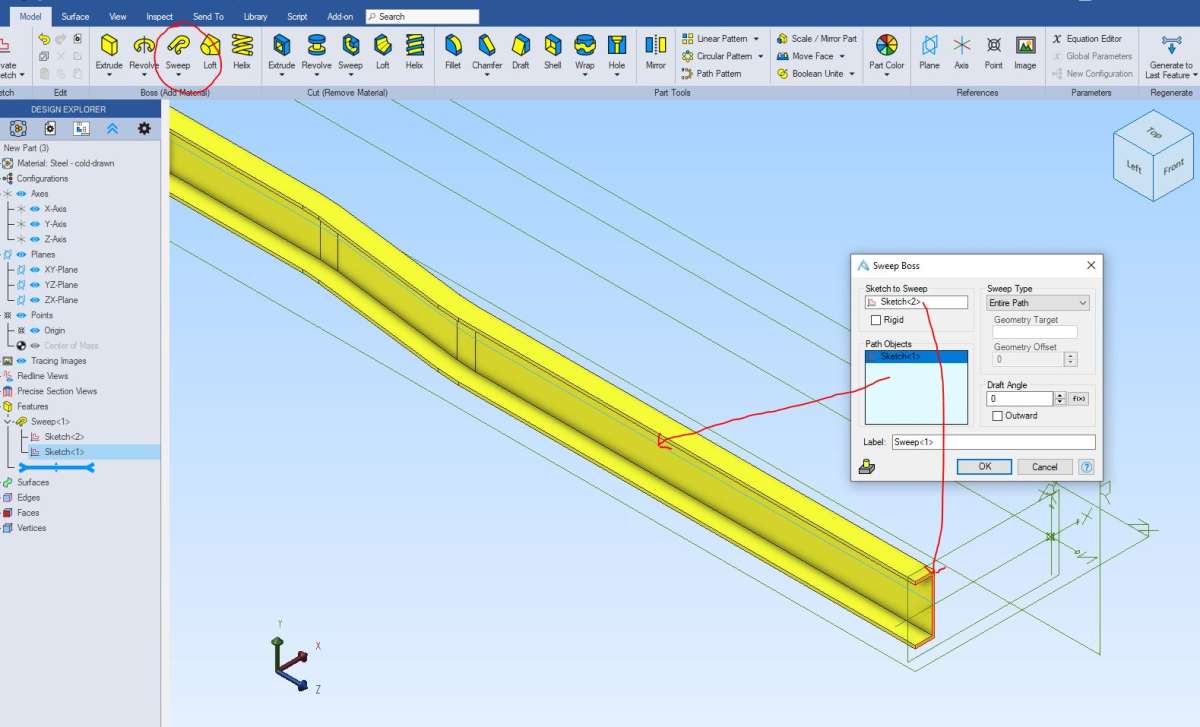

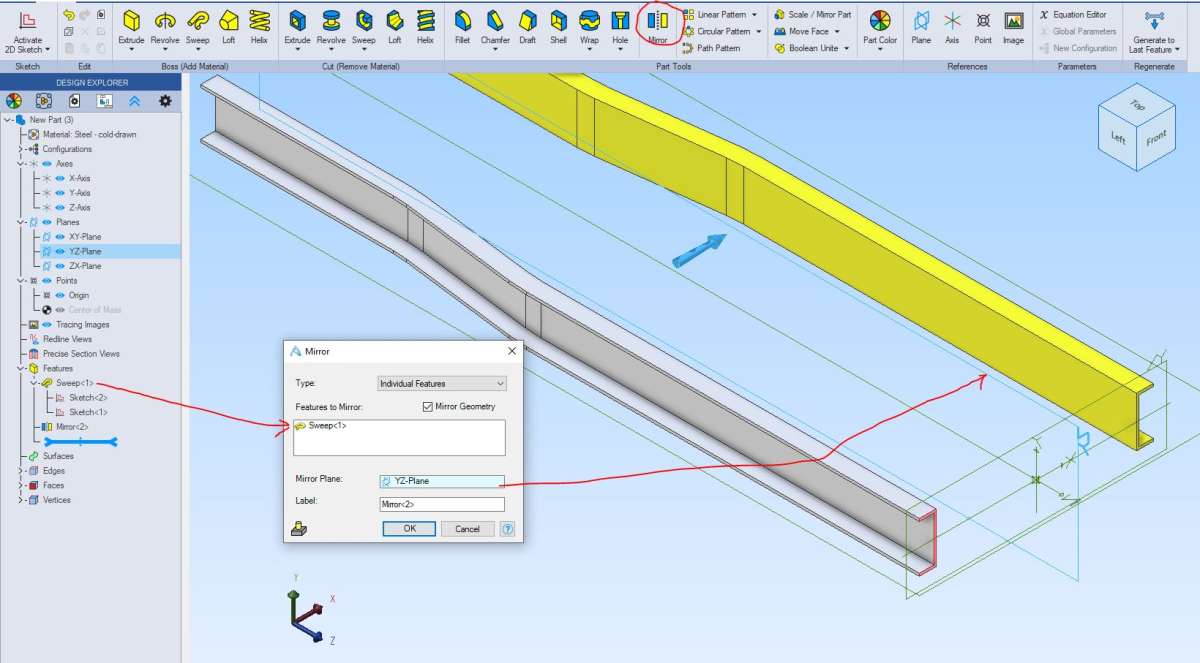

JasonBModerator@jasonb4 steps to a pair of chassis rails.

1. Select the

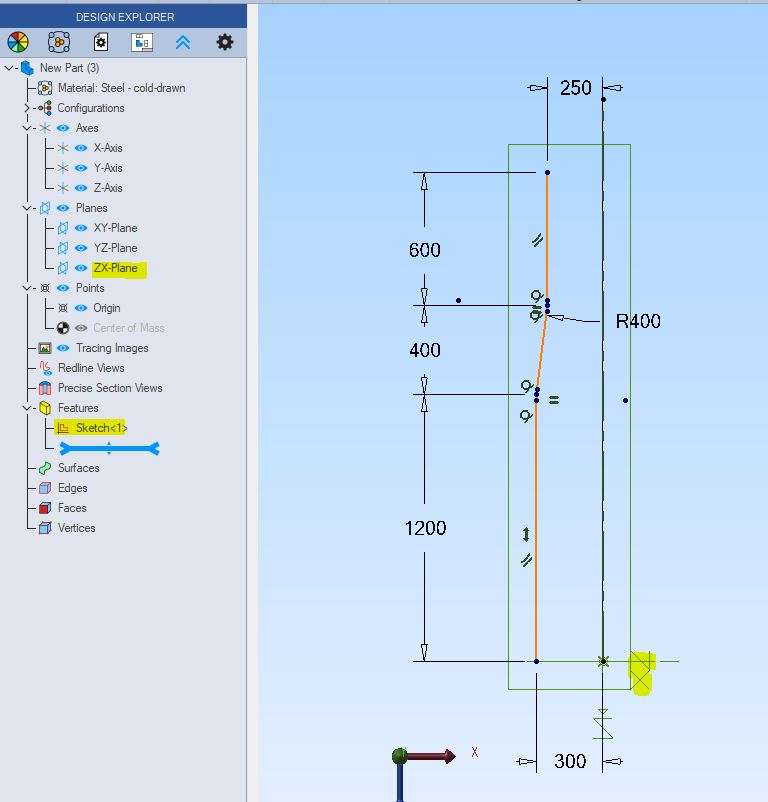

YZZX plane on the tree down the left of the screen and click “activate 2D Sketch. The axis and plane swill move on the screen but the orientation is looking at the top of the chassis, rear at the bottom of the screen, front at the top.Draw three lines to represent the rear, angled and front inner edges of the left hand rail. You can then dimension their lengths and the distance from the centre line of the chassis. I have just used random numbers but assuming at the rear there is 600mm between the two rails you can enter that dimension as 600/2 and it will then show it as the 300mm from ctr. This is an important dimension for future work. Don’t worry about the angle of the middle part it will sort itself out from the lengths and offsets of the straight parts.

If you want use the fillet tool to add some large radii to the bends but probably leave that off for now, you can go back and edit the sketch later to include them.

When you deactivate the sketch it will give a warning that it is not closed, this is OK as it is just a guide line so click ignore

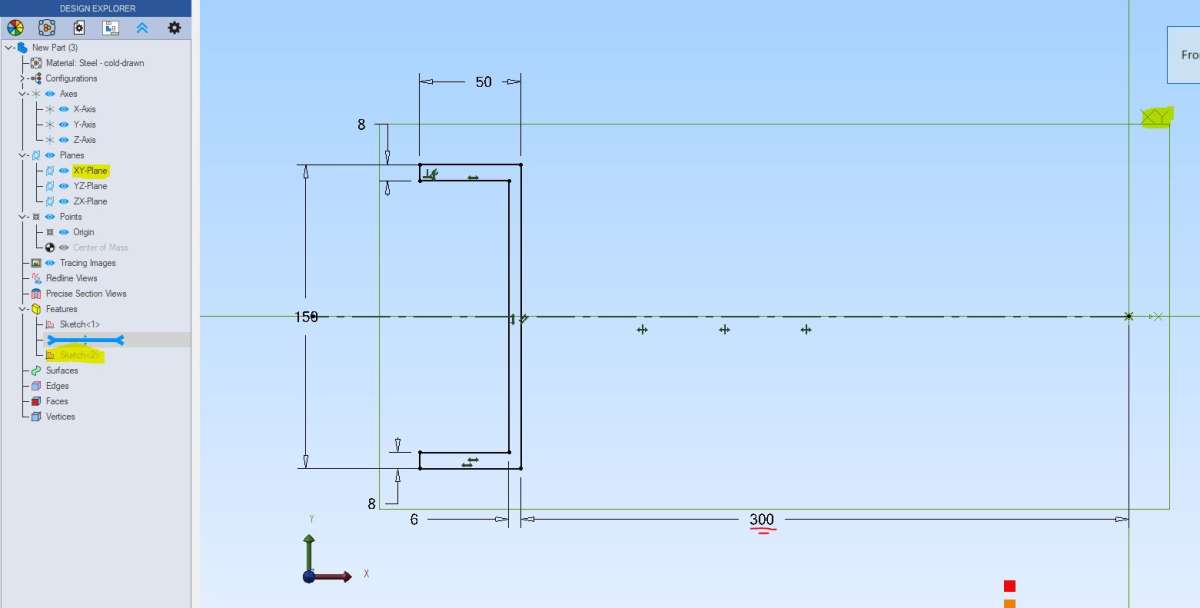

2. Click the XY plane, again the orientation will move about and leave you looking at the rear of the chassis. Sketch the C shape of the left hand chassis leg. I did a rectangle then added the three inner lines and trimmed the bit of rectangle to open up the C but any way will do. Symmetry tool set it equally above and below the mid line. It is important that you enter the same 600/2 or 300mm dimension so that in the next stage your guide line meets the inner edge of the C shaped sketch. You can then deactivate the sketch, should not get a warning on this one and you will see the two sketches in red meet each other.

3. Now rather than just do a straight extrude of that C shaped sketch we want it to follow the line of the first sketch. So select “sweep” my icons are a bit differently arranged but it is the same icon on yours. The sweep box will come up an dmay well already fill in some of the boxes but you want to click on sketch one as the path object and sketch 2 as the sketch to sweep

You could do the mrror in the assembly but may be easier here. Click the mirror icon, select the sweep as the item you want to mirror, you can click it from th eleft hand tree or simply click the part on the main screen. Select the central YZ plane a sthe one to mirror it in.

10 January 2025 at 10:47 #776173

10 January 2025 at 10:47 #776173David Jupp

Participant@davidjupp51506Nigel – perhaps I wasn’t clear. Using separate part files is not a problem, it is good. The problem comes if you copy files using standard Windows commands instead of using ‘Save as’ within Atom.

Example: You have made Left Rail and saved it – with the file still open use ‘Save as’ to make a new file Right Rail – you add a part scale/mirror in that file and save it. You now have Left & Right rails.

You must not make first file, then copy/paste & rename in Windows Files Explorer to make the second file – if you do that you’ll have 2 files with the same internal ID reference. When placed in an assembly, the software can’t differentiate them and that leads to chaos and random exchange of parts.

10 January 2025 at 11:11 #776187Chris Gunn

Participant@chrisgunn36534Nigel, I sympathise with your predicament, in struggling with the 3d cad. When I was working, I started with dos based 2D Generic cad, and got really fast at it, i was using it every day up until I retired. Then my old dos computer gave up the ghost, and I started to play about with a windows based cad, and found it more difficult. I put this down to having many more options, and the fact i was using it much much less frequently. Every time I had a go, I had a new learning curve, or may be remembering curve would be more accurate, before I produced anything.

Just bear in mind you don’t need 3D assembly drawings to produce your model, thousands of models/miniatures have been produced using 2D drawings. Get out in the workshop and make something instead of struggling with the cad. There are folks on here who use 3D cad all the time at work, and are good at it, so why wouldn’t they use it for their hobby too. I think it is much harder and time consuming to get good at it on a hobby basis alone. I am not sure if the reward is worth the effort.

Chris Gunn

10 January 2025 at 13:09 #776224 JasonBModerator@jasonb

JasonBModerator@jasonbI would agree that if you don’t regualary use it then it is harder the next time you come back to it. Nigel does seem to have had a go most days over the Xmas & new Year and the bits he has shown over the last week or so have shown he is making progress. I would suggest he tries to carry on with at least a couple of sessions a week, maybe just an hour each time.

I bought Alibre for hobby use and that is still what it gets most of it’s use for though it has been useful for work items too where a 3D image is a lot easier for may of my clients to understand than 2D elevations.

10 January 2025 at 13:49 #776243SillyOldDuffer

Moderator@sillyoldduffer…

Anyway the upshot is more delays in the project that’s already taken far too long, and knowing I will probably never be able to create 3D CAD models of assemblies of two or more parts.

I’m sad. Good progress all week, and now a collapse! My feeling is Nigel is trying to run before he’s learned to walk. Too intelligent, and by leaping ahead sets himself up to fail. I suggest:

- Do not attempt Assemblies before Parts have been mastered.

- Do not attempt advanced parts until basic parts have been subjugated.

- Do not attempt to learn 3D-CAD by modelling an advanced complex project like a steam tractor!

Therefore:

- Dump TurboCAD and use Alibre. Using two CAD packages more than doubles the learning load. Extremely confusing. Alibre preferred because it’s supported here.

- Spend a month doing nothing but model single simple parts. The goal is to become reasonably fluent before moving on, not producing anything practical. Centre-punch, cotton reel, cutlery, mug, screwdriver, bottle, ruler, tyre (without tread), unthreaded hex-headed bolt, cylinder head, cylinder block, girders, corned beef can (solid, then with empty interior), earth pin from a 3-pin plug, cannon barrel. Let the software do everything, do not organise files yourself, not yet! Nail planes, faces, constraints, views, XYZ, editing and other concepts. Be aware parts have to be modelled correctly, not just look OK on screen. Broken models cause severe CAD problems: fix at the earliest opportunity. Backtrack, don’t hope mistakes will self correct! Do not move on until able to model simple parts reliably.

- Complex parts next. Spend a few weeks learning advanced tools in outline. Although many are used infrequently, the operator needs to know what exists because primitives are difficult and error prone. Model a square church steeple, bent chassis rails, threaded holes and rods, helices (rifle the cannon barrel modelled earlier), curved pipes, mirrored parts, boolean operations, polar and linear patterns, and creating planes to cut at angles etc. Sections, transparency and other gizmos are worth exploring.

- Only after 3D parts are modelled reliably should assemblies be attempted. Assemblies are another learning challenge., and they depend on properly modelled parts. Learn by keeping it simple. For example, model the wooden part of a pencil as one part and it’s graphite core as a second, separate, part. Then assemble the graphite core inside the wood. Although simple, there are ways of getting it wrong. Practice with this and other simple two part alignments before attempting anything more difficult, like an engine. Once a single complex assembly is mastered, investigate assemblies of assemblies.

3D-CAD is very like real-world machining. If metal parts are wrong, they won’t fit together! Ditto, CAD parts. The advantage of CAD is errors can be detected and fixed without spending hours in the workshop cutting expensive metal into junk. But CAD has to be mastered, and it’s not pressing a few buttons!

Learning is a very personal process. As a youngster I preferred jumping in at the deep end: the challenge motivated me! Didn’t go well. After many painful failures I switched to learning basics first, far more productive. Problem was ignoring basics is building on sand.

Compromise allowed! Rather than follow my list of simple parts, Nigel might prefer to practise on his tractor’s simple parts. But at this stage I’d treat them as disposable, deliberately kept simple and used only to learn CAD. Knowing learner parts will go straight into the electronic scrap-box avoids complications. When the tractor is modelled later by a more experienced operator the parts can recreated quickly, and dependencies sorted. Any problems, go back into learning mode.

Dave

10 January 2025 at 14:03 #776245duncan webster 1

Participant@duncanwebster1Nothing wrong with building on sand, it’s a biblical old wives tale.

10 January 2025 at 15:32 #776284Weary

Participant@wearyI have been following this thread on and off for a while. Unfortunately I am going to take it a little off-topic as it is here to address the OPs specific issues – I apologise in advance – but I cannot assist him with those.

I too have TurboCad (18) & Alibre (Design v27), both for hobby use. I have had Alibre for just over a year & TurboCad (various versions) for over ten years. I have learnt a lot from this thread from those giving the OP direct assistance responding to his specific issues.

SillyOldDuffer,

Your exhortations above appears to be well intentioned but I would suggest useless to the OP. As I understand it the OP wants to carry-out his modelling now of parts etc., of direct and immediate interest and utility and learn the skills and commands necessary to do-so ‘on the job’. This is an entirely legitimate and commonly practised learning/teaching method.

From my experience there are hundreds of hours involved in following the basic learning schedule that you suggest. Even if he uses small parts of his project as the basis of learning. And all that before the OP even draws a single line of what he actually wants. In my experience learning those skills using just the Alibre videos and perhaps written resources without a mentor is extremely challenging. The issue is that it is by no means obvious what has gone wrong when a command or constraint fails to perform as anticipated. I have also found that the videos do not match my version of Alibre in some details so adding to the confusion and some commands appear to be fairly random in their application. To take just one very basic example: The ‘edit’ command, one of the most fundamental requirements, is actually quite difficult to actuate quite often! And with no clues as to why that may be the case. In my experience this sort of ‘failure’ appears quite often when one is a casual user. I fully understand and sympathise with the OPs frustration.

Some of your ‘simple parts’ that you suggest modelling are to my mind (extremely) complex, & vice-versa for some of your ‘simple’ parts.

I would not recommend the OP ‘Dump TurboCad’. OP appears familiar with it and I can assure you that it is actually a lot easier to manipulate than Alibre and far more ‘intuitive’. He might find using Alibre ‘sketching’, by which I mean 2D mode a lot easier as it is (of course) very similar to TurboCad, and then trying to ‘extrude’, create planes, & etc., from there rather than trying to work directly in 3D contrary to what has been suggested/recommended in this thread. In my experience a lot of the Alibre 3D needs a basic or initial 2D drawing on a plane or surface anyway. I have also found it useful to maintain notes in an index book of various command & operations, as they are soon forgotten, especially those that are rarely performed. Whilst I do use Alibre for my ‘hobby use’ I would not recommend it to the casual user as in my (experience-based) opinion it is far too demanding of learning-time and challenging to learn unsupported if one is using it simply as a means to an end. Others may have a different experience/opinion of course. I cannot comment on nor compare with any other 3D CAD.

I’m afraid that I cannot give the OP direct suggestions or help but only wish him luck. I’m sure that with perseverance he will prevail if he wishes to do-so. Those posters who are responding directly to specific issues are fulfilling a very useful role. I thank them for their efforts as they have been useful to me too.

Phil

10 January 2025 at 22:02 #776396Nigel Graham 2

Participant@nigelgraham2Thankyou Phil.

Well summarised!

TurboCAD was the first genuine CAD make at sensible prices for private buyers, and regularly advertised in ME and MEW. The UK agent, Paul (‘The CAD’) Tracy, also had a sales stand at our exhibitions.

I suspect he became overtaken commercially by Fusion 360, Alibre Atom and a version of SolidEdge, fairly similar to each other and quite different from TurboCAD. Those upstarts look easier to use than TurboCAD and in some, but no means all, respects perhaps they are; probably because their basic versions are far less powerful and versatile than TurboCAD’s. Then ME & presumably MEW mysteriously dropped the IMSI product – I assume because Alibre’s publisher gave MEW magazine an “Atom” tutorial series and a sales offer to readers.

It seems to me that the “hobby” or “student” editions of those 3D-first types are much more stripped versions of their fully-professional selves, than is the case for TurboCAD’s most basic variant, the “Deluxe”. Even that is very powerful, probably sufficient for many professional users – oh, and it will let us draw proper architectural drawings for our workshops, too.

Becoming frustrated by TurboCAD being so hard for me to learn – and disheartened further by the beautiful pictures on its Users’ Forum gallery – I tried its rivals as seemingly simpler. I did not like Fusion’s “in your face” approach and apparent paucity of decent tutorial material. Siemens’ SolidEdge literature seemed for professionals moving from one CAD system to another. On the other hand, Alibre did come with that introductory series in MEW. Though trying to set up a subscription did not go to plan, creating a big gap in the editions I bought. Subsequently I did obtain the series, on modelling a scribing-block.

.

So I now had two, rival CAD makes living in my computer….. Actually some of the TurboCAD Users’ Forum denizens have at least two if not three, but they really are experts who must have found them easy to learn.

Why keep two, even though their files are not really compatible?

For reasons you hint at, really.

Alibre (and its own-type rivals) assume only ever creating 3D models from which to derive the 2D, dimensioned elevations drawings more useful in the workshop. However, as you point out and I found, creating an Assembly, or general-arrangement, is a huge step up from modelling individual Parts.

TurboCAD lets you choose, rather grudgingly, 2D only or the 3D-first way. So I can draw general-arrangements directly, in 2D, relatively easily. The other systems make that far, far more difficult… probably too difficult for me.

The drawback is the files’ incompatibility, with only two formats in common; so drawing the GA in one and the parts in the other means drawing everything twice, albeit that the GA normally needs only parts’ outlines.

There are two real traps and I think they are what Jason has in mind.

One is the sheer volume of material to learn: effectively twice what sticking to one system demands. I believe we all have finite capacity and levels for learning anything, so cramming two sprawling CAD methods into the same small lump of brain is a tall order. No-one can be a polymath. It’s like a soprano rehearsing Brunnhilde’s part in The Ring “cycle” while also on tour with Tristan & Isolde! Though to be fair to her, her abilities in her own field are orders of magnitude higher than any of mine in my fields, could ever have been.

The other, I learnt long ago, is of thinking in one system while using the other. Your brain needs keep them as separate as the computer does. For example, TurboCAD and Alibre both use Constraints, but they might not be similar in function, let alone operation. Their work-planes systems are very different. TC has the more roundabout ways to set up printing, and to derive elevations from models. On the other hand, TC’s 2D mode is relatively simple, for full-power CAD; and allows partial and geometrical constructions beyond Alibre Atom’s remit.

I think I manage this division rather better than some credit me for. I struggle to use both makes of CAD fully, but because CAD is very hard to learn, not because I use both (not at the same time!)

I agree Alibre Atom is not easy to learn – nor is any major software. No, tutorial publications are not necessarily as helpful as they might be. They are a start but most are rote-exercises, not explanations. They don’t warn of the traps and how to identify and correct mistakes for which the “Undo” button is inadequate. So you don’t learn how to avoid the mistakes in future.

Some Alibre tutorial authors hardly help by giving you images of their own screens with that bizarre black background to all the annotations. Screen-grabs of small icons and labels are hard to read at the best of times, without that presentation.

.

I am pleased you found some of the posts useful too!

I am very grateful for the help many have given me, but I do struggle with something I should find quite easy by now and be using practically, as I bought it for.

If I made a mistake at all, though, it was not in trying to learn CAD. It was in thinking first SolidEdge (which I abandoned rapidly) and then Alibre Atom would be easier to learn and so more suitable for me than TurboCAD, to do essentially the same thing. I would have been better sticking with TurboCAD ‘Deluxe’ even if I never learnt its formidably powerful 3D mode for more than very simple, single items. The only advantage is that Alibre Atom is the more popular here so seeking help is easier.

11 January 2025 at 11:55 #776486Charles Lamont

Participant@charleslamont71117I don’t see any problem in using more than one CAD system.

I started with Turbocad in 1996, but by 1998 I was migrating to AutoSketch (AS) which I had started using at work and which at the time was much better.

When designing something I rarely do much in the way of pencil sketches because I very soon want to have dimensions and to see an assembly cross section. I still do most of my thinking in 2D in AS. There are currently over 1500 AS drawings on my PC. With more than 25 years invested in it, I am very comfortable with it, I will probably continue to use it for as long as I can still run it.

However, I am conscious that AS has been unsupported for many years and it may cease to function before I do. Mainly for that reason I started with OnShape (OS) as a potential alternative (while it was still in beta (they even implemented a couple of my improvement requests)). I also wanted to learn how to do 3D anyway.

I sometimes design from scratch in 3D, but generally don’t. I use OS more to see how things look and to prompt a rethink where something does not look right. There is also satisfaction to be had in working out how to get it to do something awkward. I currently have an almost complete OS model of John Wilding’s English Regulator, and the next challenges are to hang the weight and engrave the dial. I don’t yet very often produce drawings from OS, but I think I may well do so more often in future.

So I have no problem with using both, and for rather different purposes.

11 January 2025 at 12:16 #776495SillyOldDuffer

Moderator@sillyolddufferI have been following this thread on and off for a while.

Much more to this story than this thread, Nigel’s been struggling with 3D-CAD for years! Many problems come up again and again – hundreds of posts. The chassis rail problem, answer provided again here by Jason, was explained a few years ago, but for some reason it didn’t stick. Looking at the whole, I detect persistent across the board misunderstandings, not a few simple mid-project glitches.

Your exhortations above appears to be well intentioned but I would suggest useless to the OP. As I understand it the OP wants to carry-out his modelling now of parts etc., of direct and immediate interest and utility and learn the skills and commands necessary to do-so ‘on the job’. This is an entirely legitimate and commonly practised learning/teaching method.

Trouble is Nigel’s been trying for years and ‘on-the-job’ training has failed miserably. Read all his CAD posts!

From my experience there are hundreds of hours involved in following the basic learning schedule that you suggest. Even if he uses small parts of his project as the basis of learning. And all that before the OP even draws a single line of what he actually wants.

Correct, which is why I said ‘Spend a month doing nothing but model single simple parts.‘ No shortcuts.

In my experience learning those skills using just the Alibre videos and perhaps written resources without a mentor is extremely challenging. The issue is that it is by no means obvious what has gone wrong when a command or constraint fails to perform as anticipated. I have also found that the videos do not match my version of Alibre in some details so adding to the confusion and some commands appear to be fairly random in their application.

Yes difficult, Nigel desperately needs a mentor. Not being obvious isn’t a surprise – all of the 3D-CAD packages I’ve learned have that characteristic. Picking up on subtle danger signs is part of the learning. A command that suddenly greys out or produces an unexpected result, maybe a crash, often means an earlier basic step has been missed. CAD software rarely issues helpful error messages: being a stupid program, it obeys until the model is so badly damaged that it can’t implement the operators last order. Learning FreeCAD, I crashed repeatedly until realising I wasn’t quite following all the rules. Once I understood, FreeCAD stopped crashing! Ditto Fusion360 and SolidEdge. What Weary says next might be an example of an early error caused by a learner mistake coming home to roost, my bold:

… The ‘edit’ command, one of the most fundamental requirements, is actually quite difficult to actuate quite often! And with no clues as to why that may be the case. In my experience this sort of ‘failure’ appears quite often when one is a casual user. I fully understand and sympathise with the OPs frustration.

Indeed, and poor Nigel suffers badly. Such failures are fixed by learning how to drive, meaning the user cannot stay casual!

…

Some of your ‘simple parts’ that you suggest modelling are to my mind (extremely) complex, & vice-versa for some of your ‘simple’ parts.

Like as not. And I advise learners to grip them before moving on. Learners who can’t create ‘simple’ models will struggle with anything complicated. Nigel is well into ‘complicated’, partly because his Steam Tractor is a difficult object, partly because he keeps leaping ahead.

I would not recommend the OP ‘Dump TurboCad’. OP appears familiar with it and I can assure you that it is actually a lot easier to manipulate than Alibre and far more ‘intuitive’.

Again, read all of Nigel’s posts. Whilst he’s cracked a sub-set of TurboCAD, much of it remains a mystery. My dump suggestion isn’t because TurboCAD is rubbish. It’s because TurboCAD ‘ways and means’ keep bleeding into Alibre, which is different, causing confusion and mayhem! In my opinion swapping between two distinctly different complex CAD tools causes Nigel more trouble than it’s worth. Whether or not TurboCAD is ‘far more intuitive’ is in the eye of the beholder, I found it didn’t suit me! More importantly, Nigel hasn’t mastered it: if he had, no need for him to learn Alibre.

He might find using Alibre ‘sketching’, by which I mean 2D mode a lot easier as it is (of course) very similar to TurboCad, and then trying to ‘extrude’, create planes, & etc., from there rather than trying to work directly in 3D contrary to what has been suggested/recommended in this thread.

Does Alibre support that? FreeCAD, Fusion and SolidEdge don’t. (Unless I missed it!) Doesn’t help grasp 3D-modelling as a concept either, and that’s essential later.

In my experience a lot of the Alibre 3D needs a basic or initial 2D drawing on a plane or surface anyway. I have also found it useful to maintain notes in an index book of various command & operations, as they are soon forgotten, especially those that are rarely performed.

Correct!

Whilst I do use Alibre for my ‘hobby use’ I would not recommend it to the casual user as in my (experience-based) opinion it is far too demanding of learning-time and challenging to learn unsupported if one is using it simply as a means to an end.

Nigel isn’t a casual user! He’s modelling a full size steam tractor from very incomplete information, and it’s a complex object built from many complex parts that have to fit together. This is seriously advanced work requiring considerable time and effort. Could be done by making 2D drawings, balsa mock-ups, ang experimental parts, but that’s even more work, with lots of chicken and egg problems to solve. 3D-CAD saves a lot of time and effort, because everything is simulated on a computer and is relatively easy to change compared to physical objects. Only problem with 3D-CAD is learning it, which is difficult and time consuming. None of the 3D-CAD tools I’ve learned are toys.

…

Those posters who are responding directly to specific issues are fulfilling a very useful role.

Up to a point! Given Nigel’s history, I perceive his problem isn’t “how do I do this particular thing in Alibre?“, it’s “what to do when 3D-CAD basics aren’t fully understood?“.

I thank them for their efforts as they have been useful to me too.

Me too! Got two new ideas from this thread!

Phil

I have huge respect for Nigel’s efforts but 3D-CAD isn’t working. Rather than help, 3D-CAD has become an obstacle. I ask ‘what is Nigel doing with 3D-CAD that makes it so difficult?’

In principle, when engineering projects hit problems, it’s best to step back, identify the issues, change as necessary, and have another go. In Nigel’s case, ‘on the job’ and ‘in at the deep end’ learning haven’t delivered. Why not? I suggest the problem isn’t Alibre, it’s Nigel’s approach to learning 3D-CAD. Self-teaching is difficult, all to easy to miss important steps out, get the wrong end of the stick, pick up bad habits, and become thoroughly confused.

A few posts back I went so far as to suggest doing the job with 2D-drawings, because Nigel does them with aplomb. Loses all the power-assist features offered by Alibre, but that’s no loss if Nigel can’t get Alibre to work for him.

How about a collaboration; Nigel finds a partner to do the CAD work, freeing him to tackle the practical problems whilst the partner does 3D. Anyone available?

Dave

12 January 2025 at 01:05 #776638Nigel Graham 2

Participant@nigelgraham2To answer your question, what I am “doing with CAD” is only trying to learn to use it to a vaguely useful level.

I have NEVER blamed it for me finding it hard! Any more than I blame the lathe when I make a part too small – even though that can happen through wear and play in the machine.

I find CAD difficult, but have never been able to learn anything easily, quickly and beyond a limit specific to subject.

I do NOT mean the subject imposes the limit. I mean one’s mental barriers or capacity limits individual to the subject and self, so higher in some subjects in some people than in others.

Whatever the physiology, they are unpredictable, impassable and immutable. Once I reach my limit in a subject, I cannot exceed it, but can lose what knowledge I had gained. Worse, they are not linear or regular, so I may find a given part of the subject fairly easy but others of theoretically similar severity, impossible.

For example, I gained a Grade ‘A’, GCE A-Level in Geology, via evening-classes. Yet cannot learn Mathematics beyond the GCSE Level I also gained as an adult student – despite its volume and technicality being far shallower than the old GCE O-Level I attempted full-time at school. That is not the “fault” of Mathematics, but of my Nature.

In a Fifth-Form school report my maths teacher remarked on my large gaps in basic understanding that I need fill. Well, he never told me that. Anyway, he helped only the intelligent ones who liked the subject and found it easy, and he regarded anyone like me as idiots. All I knew then, and still, is that I could not and cannot learn maths – which may be relevant here, for although CAD does not expect me to be a mathematician, it may expect a similar mind.

Very different here on this Alibre-based forum, and on the TurboCAD Users’ Forum, where many people have tried to help me although I have to say they also sometimes mis-interpret me.

That shows in comments about me trying to use CAD for a complicated project before being a CAD expert. Not quite. I wanted to learn CAD enough to help my model-engineering generally, but obviously could not have predicted finding it so hard, nor my natural limits for it. I can use CAD for drawing some components no harder than the level of the tutorial exercises, so tend to use them as CAD exercises with a practical use. Once I know my limits, I can stay within them – well, I have no choice.

That cylinder-block illustrates this. I found it very difficult to draw just in its basic form, and had to create that cut-away image so I can develop the internal passages by manually editing a print. Similarly, I cannot draw the chassis in Alibre Atom 3D; only by direct 2D elevation drawings not in Alibre’s remit.

.

On which, once again, I do not think in TurboCAD when using Alibre, or vice-versa! They do the same things but in very different ways. My Myford 7 and Harrison L5 lathes will both cut threads – but one demands knowing how to manipulate its gearbox, and the other demands calculating and physically swapping gears.

TurboCAD lets me create 2D drawings directly, too difficult to do via 3D models. That’s important for complicated components or umpteen-part assemblies I could never model in 3D in either system. On the other hand I can use Alibre to draw single, simple parts via its 3D-first method.

In a way they complement each other despite file-type incompatibility: one will let me do what I can’t in the other; but this is not fully reciprocal and I could not use either to its full potential.

Alibre Atom overall seemed simpler to learn, and everyone else on here so praised it or its similar-class rivals. It isn’t simpler, just different; but everyone else also found CAD easy to learn irrespective of its make.

.

One or two here say I am “intelligent”. I take it as a compliment, but it bleakly amuses me. Various people over the years have said it; even claimed I was “very intelligent” when a lad. No, I was only ever of “average intelligence”, probably less. However you try to define and measure – or just guess – such an elusive, subjective, individual, natural characteristic.

.

I am afraid I take it your last suggestion is in jest. For making accessories for a Myford 7, or re-drawing old, published model plans, fair enough. For a project like mine, no. An “external” designer would need be not only a CAD expert but also know the work so far, built with no original drawings, very few new ones, and very many revisions and corrections.

12 January 2025 at 07:01 #776640 JasonBModerator@jasonb

JasonBModerator@jasonbSo back to getting some bits drawn, have you had another go at those chassis rails like I showed? Spend the time you took on that long reply to Dave’s even longer post practicing with Alibre.

Have a go and if something goes wrong just take a screen shot and post it here rather than deleting.

Your other two methods of drawing the part were also quite viable so again if you want to try those do so and if it fails save and post a screen shot. Even if it does not help you there are others following and learning.

12 January 2025 at 09:59 #776665 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133So back to getting some bits drawn […] Have a go and if something goes wrong just take a screen shot and post it here rather than deleting.

Your other two methods of drawing the part were also quite viable so again if you want to try those do so and if it fails save and post a screen shot. Even if it does not help you there are others following and learning.

Speaking as one of those others … Yes, Please !

MichaelG.

12 January 2025 at 12:45 #776711Nick Wheeler

Participant@nickwheelerYour other two methods of drawing the part were also quite viable so again if you want to try those do so and if it fails save and post a screen shot. Even if it does not help you there are others following and learning.

It’s worth trying the other methods, as they are all the virtual equivalents of different fabrication methods – model using a sweep is the same as using heat to shape a single piece rail; modelling three separate but joined pieces is how you would weld it together. Neither would be done by you calculating the joining angles, as the computer can do it for you. In fact it can do it far more precisely than you can, which saves you time and effort later on. This is another reason how designing in CAD can save you lots of time and effort when actually making the part(which is the only bit in the process that matters) as you will already have thought through some of the problems. It’s quicker, easier and wastes less material than discovering any problems half way through mangling an expensive piece of metal…

12 January 2025 at 14:10 #776727Nigel Graham 2

Participant@nigelgraham2Jason –

I have printed your instructions for when I feel able top try again, as a better (and more permanent) way to follow them than trying switch back and forth between windows.

Nick –

Wouldn’t “Sweep” treat the entire section as a double bend? That would not be correct, and give me more headaches trying to locate components on them. For the channel is straight between short curves with very vague end-points and unknown radii.

The bender had a simple pad as moving “die” and square blocks as fixed ones, not radiused grooves as on a pipe-bender, so the steel followed material-physics and chalk-lines on the floor.

I could not see any other way than to draw the thing as straight bits cut and welded, by trimming their ends by angle. I should have trimmed both ends of only the angled piece, and by the full 4º angle, not all four mating ends by half-angles. The way the parts swung around made it impossible to see which end was which as the cut-off was invisibly small on the screen, so I added those “free” holes to indicate them.

Making the beam as if welding a 3/16″ thick flange along a dog-legged strip five-feet long by one-inch wide, proved impossible. If it fits the drawing window the web is only a line on the screen. If I enlarged it to see each section of the web edge-on, I could not control how it reacted to the clusters of thick red lines and big black dots. It always plumped for the wrong ones. Then when I finally created very long, very narrow rectangles, they either overlapped each other, producing an error; or were slightly short as if sawn through.

I started to think to Hell with trying to draw it at all realistically, but as either a very thin edge-on strip (web with no flanges to screw anything to), or solid 2 X 1 inch bar.

I had recognised the intrinsic advantages of CAD as you say even, before I first bought it.

I knew firstly it is far quicker, easier and more accurate to create and edit electronic drawings than on paper. Secondly, I realised it facilitates verifying the design before cutting any metal.

It doesn’t take over the house either, as an industrial A0 drawing-board does!

This assumes managing to learn to use it fully though. If I can’t draw complete assemblies or complicated parts only the first advantage helps me, and then only to a limited extent.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Pattern Makers Vice

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 4

- 4

-

2 July 2025 at 06:13

Speedy Builder5

-

Motor won’t start

Started by:

Rowan Sylvester-Bradley in: Beginners questions

- 6

- 6

-

1 July 2025 at 23:52

noel shelley

-

Meddings MF4 Manual

Started by:

Richard Kirkman 1 in: Help and Assistance! (Offered or Wanted)

- 10

- 20

-

1 July 2025 at 23:42

JohnF

-

Speed camera

Started by:

David George 1

in: The Tea Room

David George 1

in: The Tea Room

- 14

- 16

-

1 July 2025 at 23:25

Nigel Graham 2

-

J&S grinder – belt which way ?

Started by:

gerry madden in: Manual machine tools

- 5

- 6

-

1 July 2025 at 22:53

Chris Crew

-

IME Watchmakers lathe

Started by:

Greensands in: Manual machine tools

- 11

- 16

-

1 July 2025 at 21:41

Dave S

-

Request for a Slot to be Milled in a Shaft

Started by:

James Alford in: Help and Assistance! (Offered or Wanted)

- 9

- 18

-

1 July 2025 at 21:03

bernard towers

-

Bearing boxes for ball race

Started by:

Paul McDonough in: Beginners questions

- 9

- 17

-

1 July 2025 at 21:02

Paul McDonough

-

Twin Engineering’s heavy mill/drill quill removal

Started by:

Martin of Wick in: Manual machine tools

- 7

- 9

-

1 July 2025 at 20:51

Martin of Wick

-

The Stevenson Trophy – Entries Invited

Started by:

Neil Wyatt

in: Website Announcements

Neil Wyatt

in: Website Announcements

- 1

- 2

-

1 July 2025 at 18:44

Neil Wyatt

Neil Wyatt

-

The Bradford Cup – Nominations Wanted

Started by:

Neil Wyatt

in: Website Announcements

Neil Wyatt

in: Website Announcements

- 1

- 2

-

1 July 2025 at 18:41

Neil Wyatt

Neil Wyatt

-

FreeCAD v1.0 tutorials

1

2

3

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 12

- 54

-

1 July 2025 at 18:31

Speedy Builder5

-

Haining vertical dairy engine boiler.

Started by:

apprentice in: Beginners questions

- 2

- 2

-

1 July 2025 at 18:26

JasonB

JasonB

-

All things Beaver Mill

1

2

…

8

9

Started by:

Robert James 3 in: Manual machine tools

- 43

- 208

-

1 July 2025 at 18:22

Charles Lamont

-

Dial test indicator vs Dial indicator

Started by:

martian in: Workshop Tools and Tooling

- 17

- 24

-

1 July 2025 at 16:59

Clive Foster

-

Help for DIY lathe build.

1

2

Started by:

moogie in: Help and Assistance! (Offered or Wanted)

- 16

- 32

-

1 July 2025 at 15:21

David Senior

-

Firth Valve Gear

Started by:

Andy Stopford in: Traction engines

- 9

- 18

-

1 July 2025 at 12:59

Nigel Graham 2

-

M type top slide conversion??

Started by:

jimmyjaffa in: Beginners questions

- 7

- 11

-

1 July 2025 at 11:35

David George 1

David George 1

-

Offen screw type telescopic gauge.

Started by:

Graeme Seed in: Workshop Tools and Tooling

- 4

- 9

-

1 July 2025 at 10:41

Graeme Seed

-

2 Machine lights

Started by:

modeng2000 in: Workshop Tools and Tooling

- 2

- 6

-

1 July 2025 at 08:57

Dalboy

-

New member looking for help

Started by:

manfromthemist

in: Introduce Yourself – New members start here!

manfromthemist

in: Introduce Yourself – New members start here!

- 11

- 24

-

1 July 2025 at 08:19

Juddy

-

Wiring up a single phase AC motor with 4 wires

Started by:

ell81 in: Beginners questions

- 6

- 8

-

30 June 2025 at 19:49

Howard Lewis

-

New (old!) member

Started by:

iansoady in: Introduce Yourself – New members start here!

- 3

- 3

-

30 June 2025 at 19:30

Howard Lewis

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 178

-

30 June 2025 at 12:58

Paul Kemp

-

High strength 4mm steel?

1

2

Started by:

iansoady in: Materials

- 20

- 31

-

30 June 2025 at 10:55

JohnF

-

Pattern Makers Vice

-